Intelligent belt tension constant keeping device and method

A technology of intelligent belts and holding devices, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as reducing labor intensity of employees, low monitoring efficiency, and accelerating belt damage, so as to reduce labor output and work High reliability and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

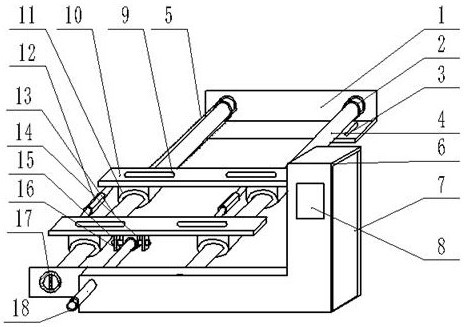

[0033] An intelligent belt tension constant maintaining device includes a motor sliding base and a constant tension maintaining mechanism. The motor sliding base includes a motor base, a sliding rod, and a driving screw. The drive motor base makes reciprocating linear motion on the slide bar.

[0034] The constant tension maintaining mechanism includes a motor, a drive sprocket, a first sprocket, a drum, a gravity bucket, a second sprocket, and a third sprocket.

[0035] The drive sprocket is set on the output shaft of the motor, the first sprocket is connected to the drive sprocket through a chain, and the first sprocket and the second sprocket are coaxially arranged with the drum; the gravity bucket is hooked to the drum by winding the drive rope; The third sprocket is arranged at the end of the driving screw rod.

[0036] The third sprocket is connected to the second sprocket through a chain transmission; wherein, the first sprocket and the second sprocket are one-way spro...

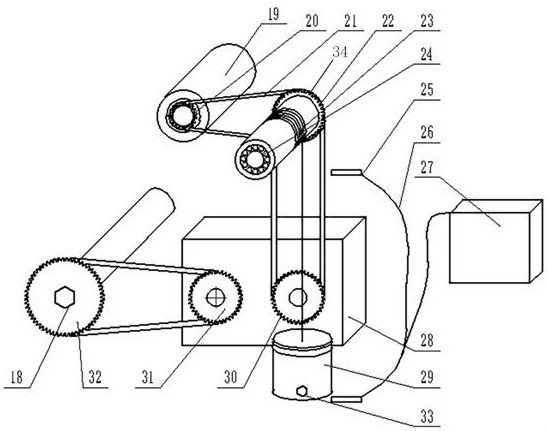

Embodiment 2

[0038] An intelligent belt tension constant maintaining device also includes a torque amplification box, the torque amplification box is provided with an input sprocket and an output sprocket; the input sprocket is connected to the second sprocket; the output sprocket is connected to the second sprocket Three-sprocket drive connection.

[0039] There is a gear set inside the torque amplification box. Using the principle of leverage, the torque transmitted from the second sprocket to the input sprocket is amplified and transmitted to the output sprocket, so as to achieve the effect of producing a large tensioning torque with a small input torque.

Embodiment 3

[0041] An intelligent belt tension constant maintaining device also includes a motor controller and a position sensor, the position sensor is connected to the motor controller, and the position sensor includes an upper limit position sensor and a lower limit position sensor; the upper limit position sensor is arranged on the The upper limit position of the gravity barrel, the offline position sensor is set at the lower limit position of the gravity barrel.

[0042] The motor controller has functions such as motor start and stop, motor speed regulation, etc., and is used to control the motor.

[0043] The position sensor is a proximity position sensor, which is used to sense the position of the gravity barrel and transmit the switch signal to the motor controller at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com