Composite film for photocathode protection and its preparation method and application

A technology of photocathode and composite film, which is applied in the direction of electrolytic inorganic material plating, coating, etc., can solve the problems of unsatisfactory photoelectrochemical cathodic protection effect, inability to transfer photogenerated electrons quickly, and ineffective use of solar energy, etc., to achieve the goal of expanding light Effects of absorption utilization efficiency, high-efficiency photocathode protection, and low conduction band potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

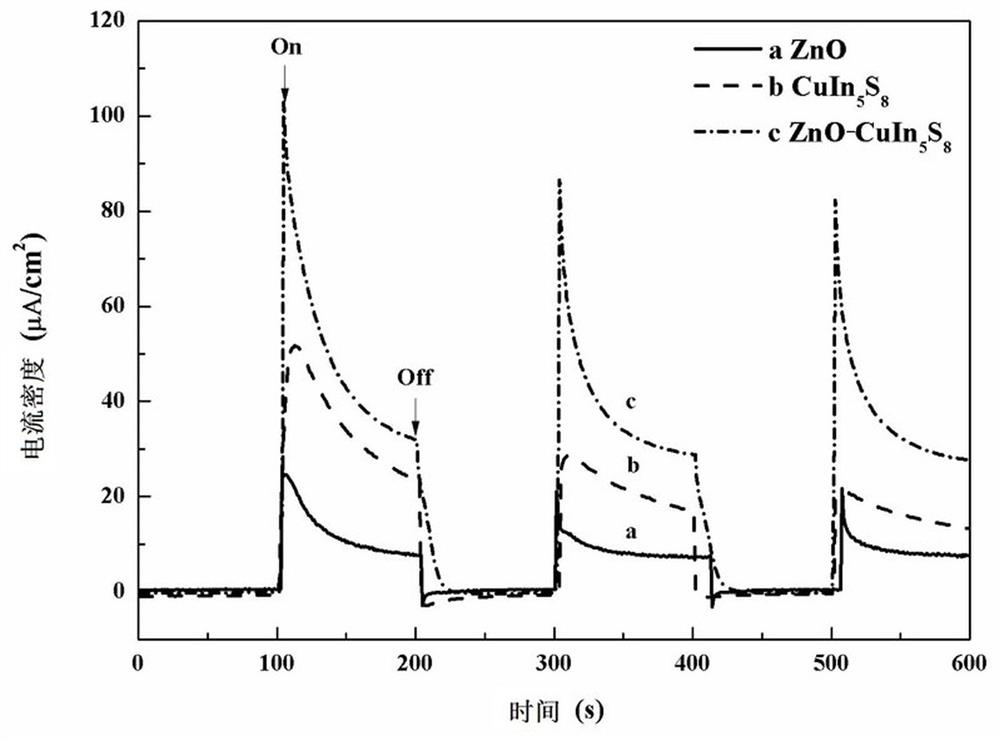

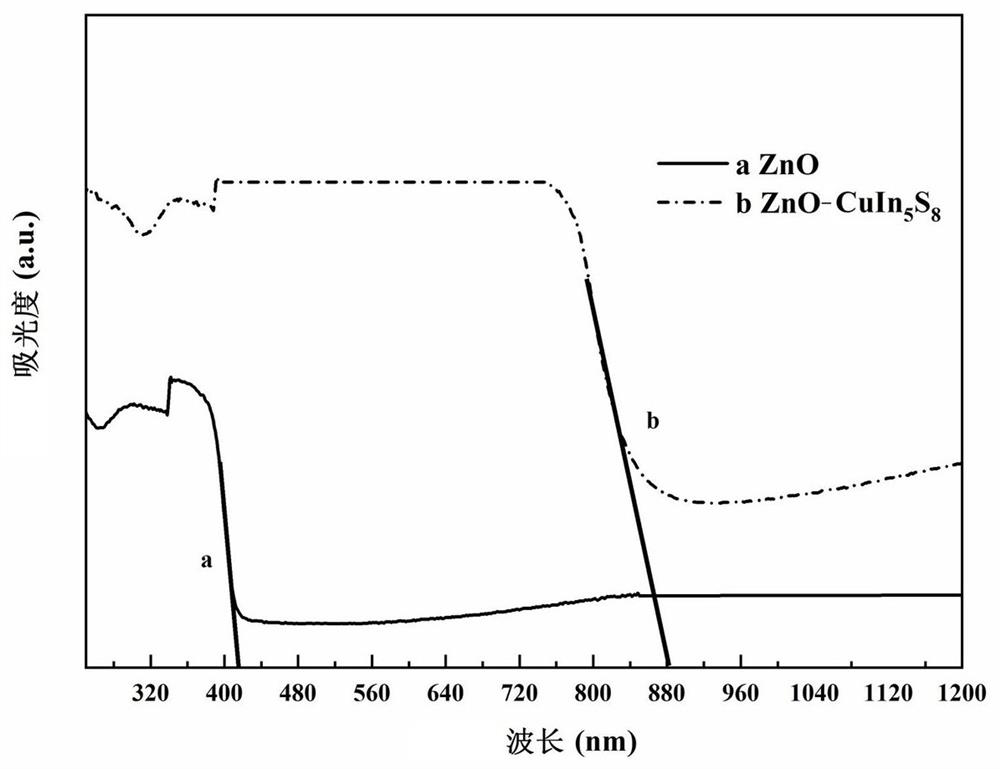

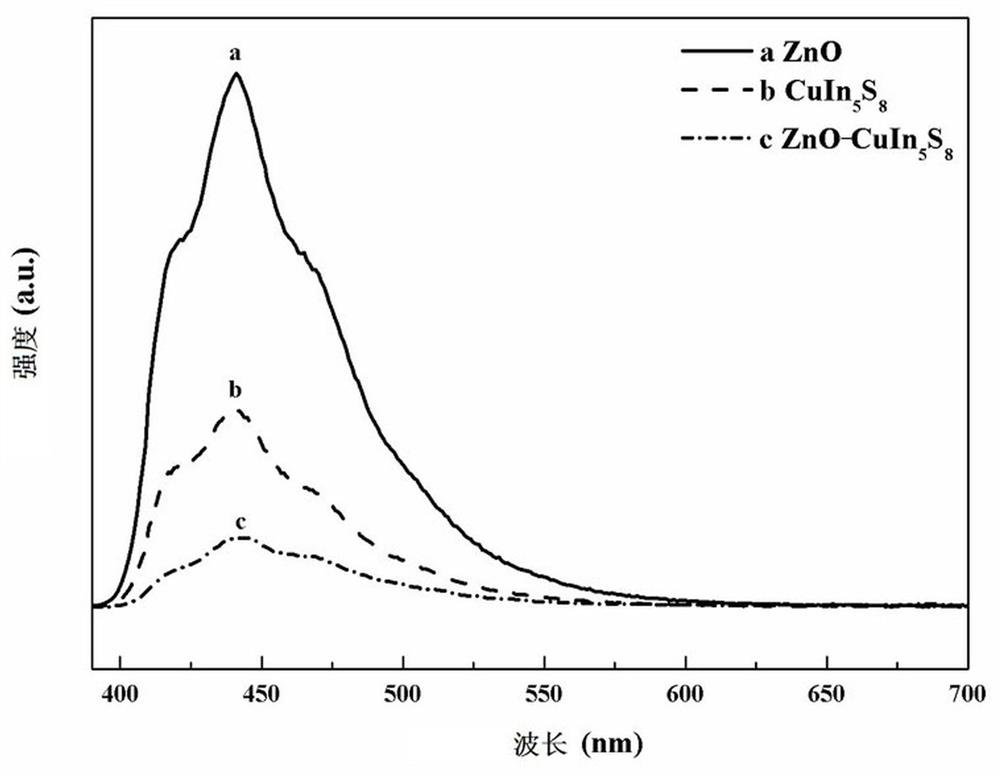

[0033] The present invention aims at the unsatisfactory problem of the photoelectrochemical cathodic protection effect existing in the semiconductor material that the current photocathode protection photoanode adopts, and provides a kind of preparation method of the composite film that is used for photocathode protection, comprises the following steps:

[0034] (1) cleaning and acid-treating the conductive glass; (2) depositing ZnO nanowires on the surface of the conductive glass obtained in step (1) by electrodeposition; (3) depositing ZnO nanowires on the surface of the ZnO nanowires by hydrothermal method deposited CuIn 5 S 8 , resulting in ZnO-CuIn 5 S 8 The composite membrane is the composite membrane used for photocathode protection.

[0035] In a preferred embodiment of the present invention, the cleaning includes sequentially placing the conductive glass in the first solution, the second solution, the third solution and the fourth solution to perform ultrasonic clea...

Embodiment 1

[0054] 1. The ZnO-CuIn used for photocathode protection in this embodiment 5 S 8 The preparation method of composite membrane may further comprise the steps:

[0055] (1) Before the hydrothermal reaction experiment, it needs to be thoroughly cleaned. The purpose is to improve the adhesion between the film and the glass. Put the ITO conductive glass into the aqueous solution containing detergent, the ethanol solution of NaOH, the acetone and in a beaker of deionized water, and ultrasonically cleaned for 10 minutes to clean it. Then soak in dilute hydrochloric acid with pH = 1 for 2-3 minutes to make the surface adsorb a large amount of H + , rinsed with deionized water and dried at 60°C for later use.

[0056] (2) Add 500mmolL to the electrolytic cell -1 The mixed solution of zinc sulfate and KCl is adjusted to pH = 1 with sulfuric acid to obtain an electrochemical deposition solution. A three-electrode system is used, with the ITO conductive glass obtained in step (1) as ...

Embodiment 2

[0064] 1. The ZnO-CuIn used for photocathode protection in this embodiment 5 S 8 The preparation method of composite membrane may further comprise the steps:

[0065] (1) Before the hydrothermal reaction experiment, it needs to be thoroughly cleaned. The purpose is to improve the adhesion between the film and the glass. Put the FTO conductive glass into the aqueous solution containing detergent, the ethanol solution of NaOH, and the ethanol in order. and a beaker in deionized water, and ultrasonically cleaned for 20 minutes to clean it. Then soak in dilute hydrochloric acid with pH = 6 for 2-3 minutes to make the surface adsorb a large amount of H + , rinsed with deionized water and dried at 100°C for use.

[0066] (2) Add 1molL to the electrolytic cell -1 The mixed solution of zinc acetate and NaCl was adjusted to pH=1.5 with sulfuric acid to obtain an electrochemical deposition solution. Using a three-electrode system, the FTO conductive glass obtained through step (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com