Preparation method of artificial turf

A technology of artificial turf and artificial turf, which is applied to textiles and papermaking, roads, and pavement details, etc. It can solve problems such as shedding, loosening of artificial turf, and damage to the structure of woven artificial turf, so as to prevent loosening and falling off and improve service life. , The effect of increasing water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

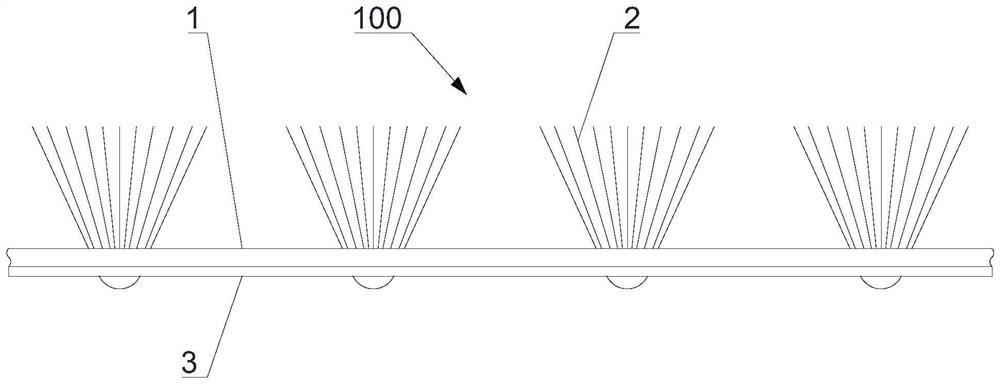

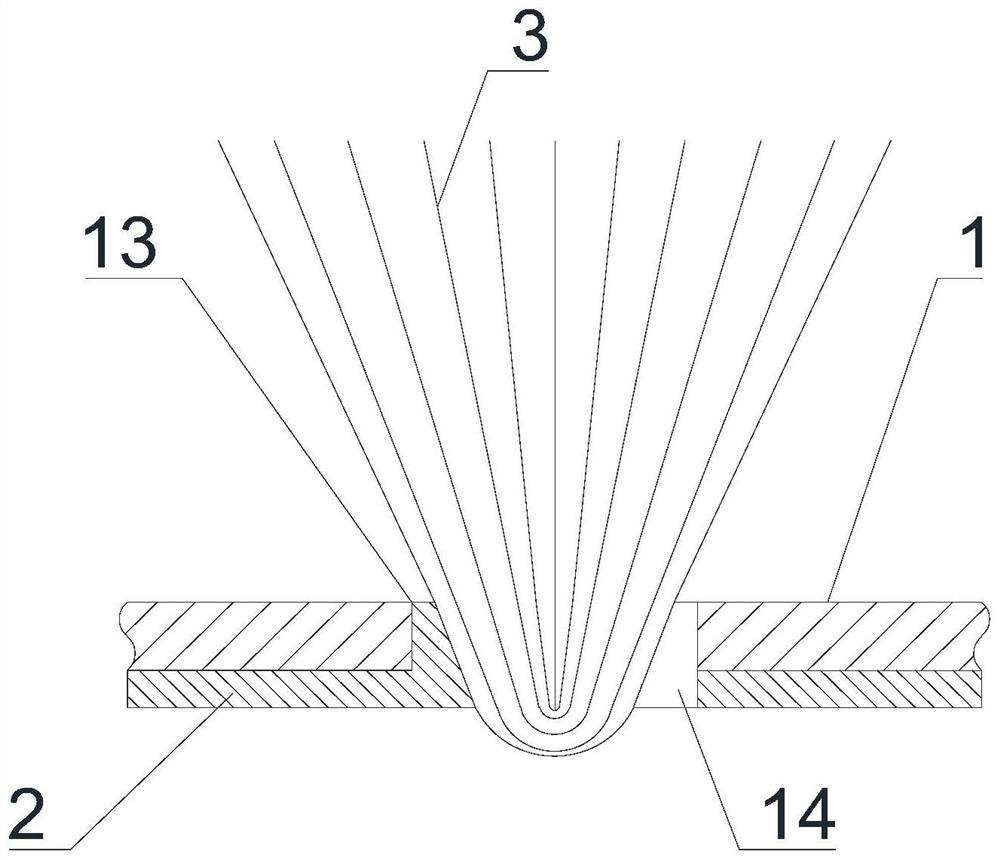

[0034] The present invention also provides a method for preparing the artificial turf 100, comprising the following steps:

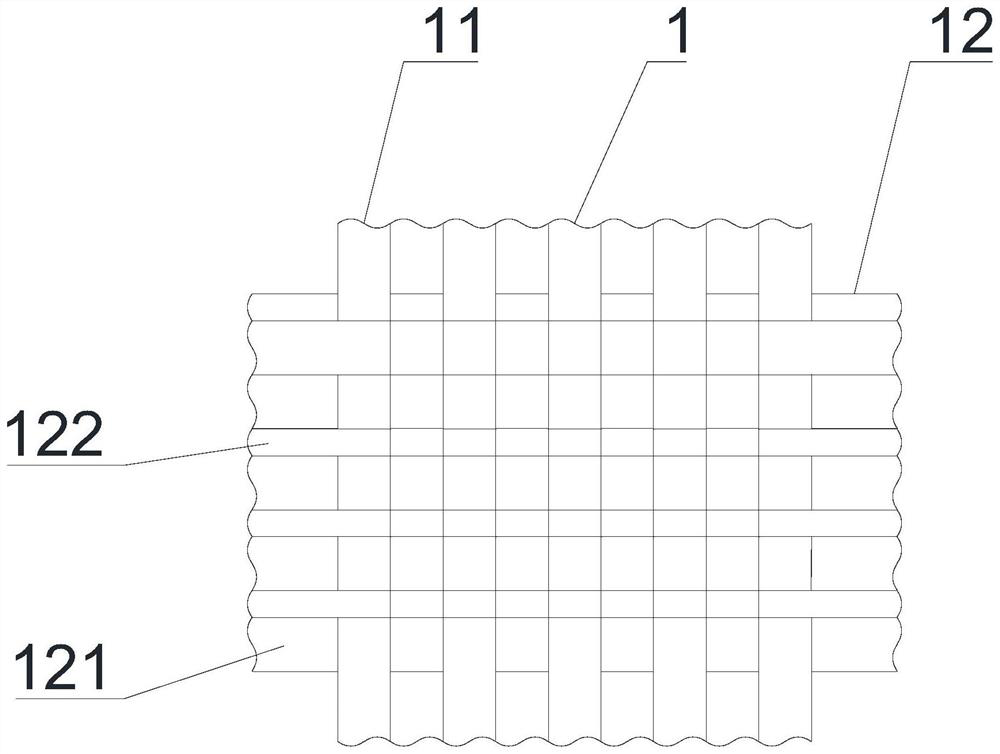

[0035] (1) Select the warp thread 11 and the weft thread 12 , place the warp thread 11 and the weft thread 12 on a knitting machine for weaving, shaping, and rolling to obtain the base fabric 1 .

[0036] (2) Put the pellets in the wire drawing machine, add drawing liquid into the wire drawing machine, control the drawing temperature to 100-150°C, and the shrinkage ratio to 0.90-0.98, and carry out wire drawing treatment on the mixed pellets through the wire drawing process, winding, Shape, curl, and obtain artificial grass silk 2.

[0037] (3) The artificial turf silk 2 prepared in step (2) is tufted and implanted on the base cloth 1 prepared in step (1) by a tufting machine, and the tufting machine perforates a plurality of pinholes 13 on the surface of the base cloth 1 , the adhesive is coated on the surface of the base cloth 1 by scraping or roller ...

Embodiment 1

[0040] The preparation method of the artificial turf of the present embodiment comprises the following steps:

[0041] (1) Selecting the warp thread and the weft thread, placing the warp thread and the weft thread on a knitting machine for weaving, setting the shape, rolling up, and obtaining the base fabric.

[0042] (2) Put the polyethylene pellets in the wire drawing machine, add drawing liquid to the wire drawing machine, control the drawing temperature to 100°C, and the shrinkage ratio to 0.90, and carry out wire drawing treatment on the mixed pellets through the wire drawing process, winding, shaping, Roll it up to get artificial turf.

[0043] (3) The artificial turf silk prepared in step (2) is tufted and implanted on the base cloth prepared in step (1) by a tufting machine, the adhesive is coated on the surface of the base cloth, and the The base cloth is blown by an air blowing device at an air pressure of 1 MPa, and after the adhesive is cured, it is rolled up and ...

Embodiment 2

[0045] (1) Selecting the warp thread and the weft thread, placing the warp thread and the weft thread on a knitting machine for weaving, setting the shape, rolling up, and obtaining the base fabric.

[0046] (2) Put the polypropylene pellets in the wire drawing machine, add drawing liquid to the wire drawing machine, control the drawing temperature to 110°C, and the shrinkage ratio to 0.92, and carry out wire drawing treatment on the mixed pellets through the wire drawing process, winding, shaping, Roll it up to get artificial turf.

[0047](3) The artificial turf silk prepared in step (2) is tufted and implanted on the base cloth prepared in step (1) by a tufting machine, the adhesive is coated on the surface of the base cloth, and the The base cloth is blown with air pressure of 2 MPa by the air blowing device, and after the adhesive is cured, it is rolled up and packaged to obtain artificial turf.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com