Chemical catalytic furnace with high sealing performance

A chemical catalysis and sealing technology, applied in the field of catalytic furnaces, can solve the problems of adding different types of catalysts, unable to continue to add catalysts, etc., and achieve the effect of improving the catalytic effect and improving the catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

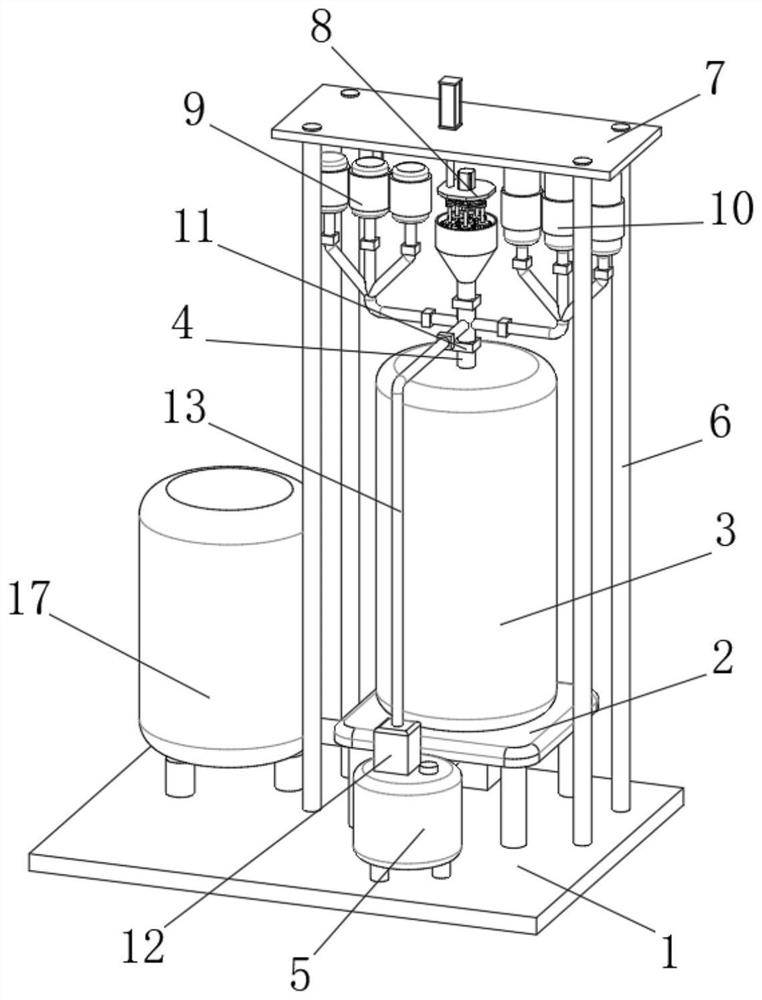

[0032] see Figure 1-8 , the present invention provides a technical solution:

[0033] A chemical catalytic furnace with high airtightness. When the device is in use, solid, liquid or gaseous catalysts are respectively added into the catalytic tube 4 through the solid catalyst adding mechanism 8, the liquid catalyst adding mechanism 9 or the gaseous catalyst adding mechanism 10, and catalyzed The tube 4 is installed in the catalytic furnace 3, and the catalytic furnace 3 is fixedly connected to the surface of the base 1 through the installation platform 2, so that the catalytic furnace 3 can be fixed and operated in a safe and stable environment, and the bottom surface of the installation platform 2 is fixedly connected with The heating furnace 14, the heating furnace 14 is connected with the fuel tank 17 installed on the base 1 through the fuel pipe 16, the heating furnace 14 can be operated for a long time through the fuel tank 17, and the continuous operation of the heating...

Embodiment 2

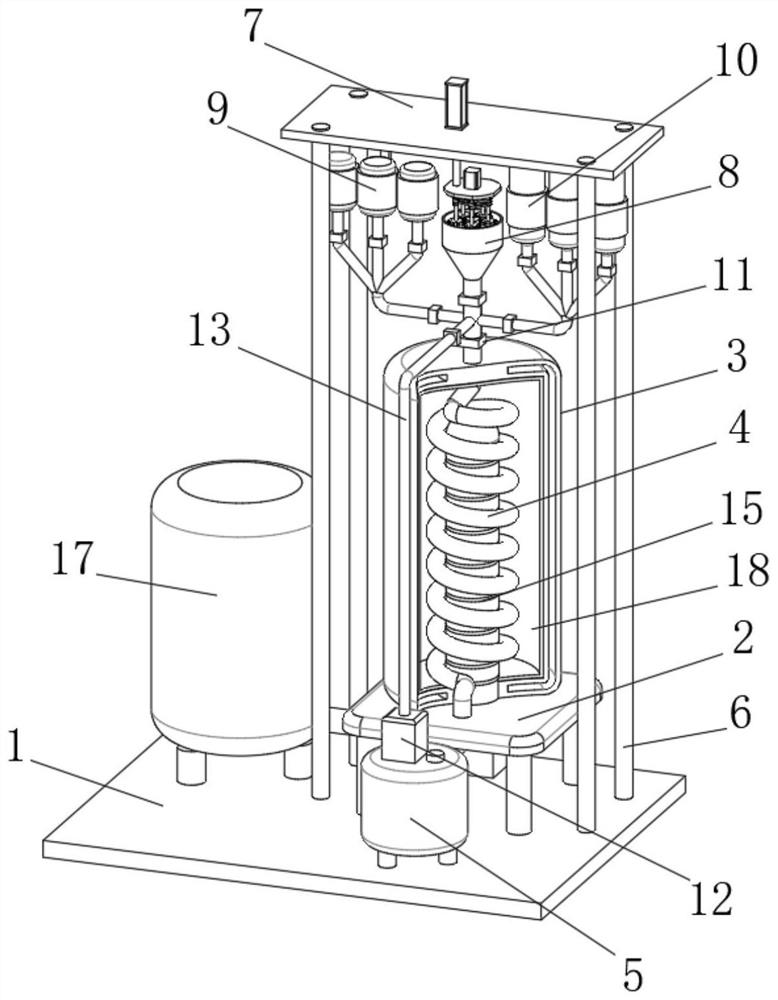

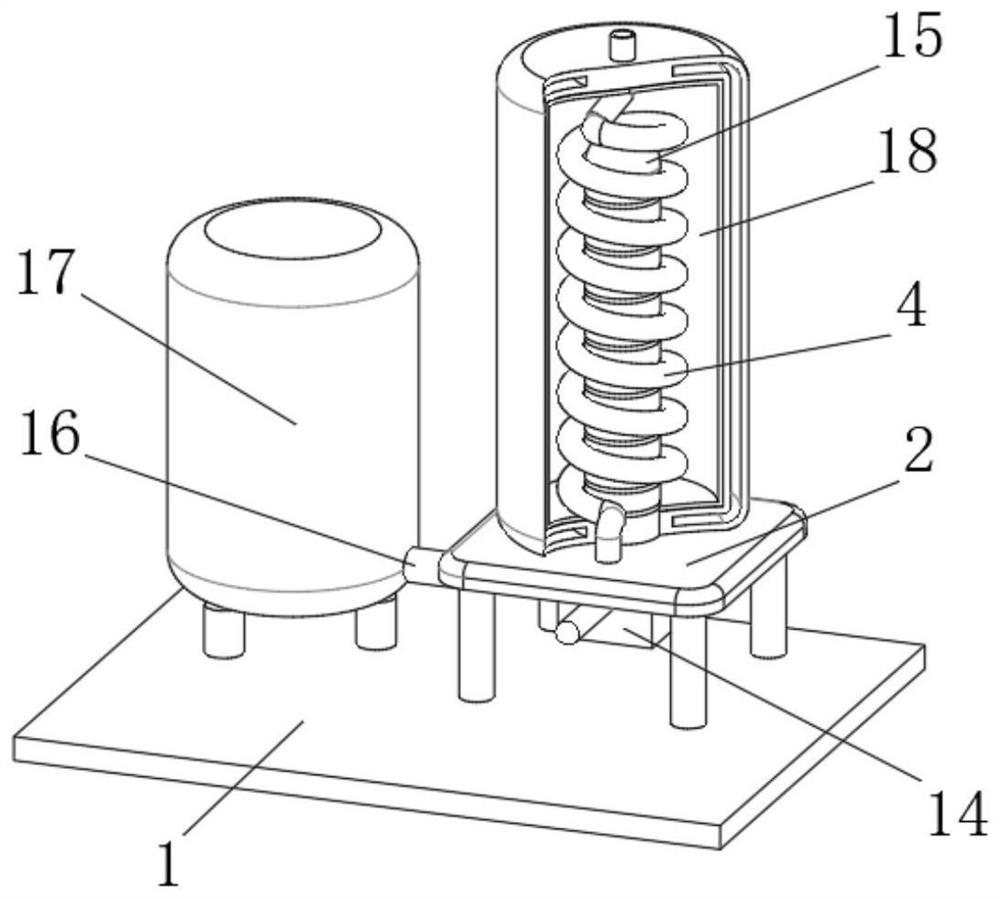

[0038] see Figure 1-8, on the basis of Embodiment 1, the present invention provides a technical solution:

[0039] A chemical catalytic furnace with high sealing performance. A pump body 12 is installed inside the waste gas barrel 5. A return pipe 13 is hollowly connected above the pump body 12, and the return pipe 13 is hollowly connected with the upper part of the catalytic pipe 4. The return pipe 13 The connection with the catalytic tube 4 is located above the electromagnetic valve 6 11, and the inside of the return tube 13 is equipped with a heating furnace 14, so that the solid catalyst adding mechanism 8, the liquid catalyst adding mechanism 9, and the gaseous catalyst adding mechanism 10 flow into the catalytic tube 4. After the catalyst is added for one catalysis, the exhaust gas may not be fully catalyzed. When the heating furnace 14 is turned on, the exhaust gas is pumped from the return pipe 13 into the exhaust gas barrel 5 again through the pump body 12, and refil...

Embodiment 3

[0042] see Figure 1-8 , on the basis of Embodiment 2, the present invention provides a technical solution:

[0043] A chemical catalytic furnace with high airtightness, solid catalyst adding mechanism 8, liquid catalyst adding mechanism 9 and gaseous catalyst adding mechanism 10 are all installed on the mounting plate 7 installed above the fixedly connected mounting frame 6 on the base 1, solid catalyst adding Mechanism 8 comprises the hydraulic cylinder 81 that is installed on the mounting plate 7 and the inlet 812 that is installed on the catalytic tube 4, can add solid chemical position in the catalytic tube 4 through the inlet 812, and the upper installation of hydraulic cylinder 81 There is a telescopic rod 82, and the bottom end of the telescopic rod 82 runs through the mounting plate 7 and is fixedly connected with a lifting platform 83. The hydraulic cylinder 81 drives the telescopic rod 82 to slide up and down connected to the lifting platform 83, so that the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com