Small hardware fitting defect detection algorithm based on machine learning

A machine learning and defect detection technology, which is applied in the direction of optical defect/defect, instrument, calculation, etc., can solve the problems of inaccurate defect detection and complicated detection process, and achieve complete removal, fast noise reduction, brightness and color Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

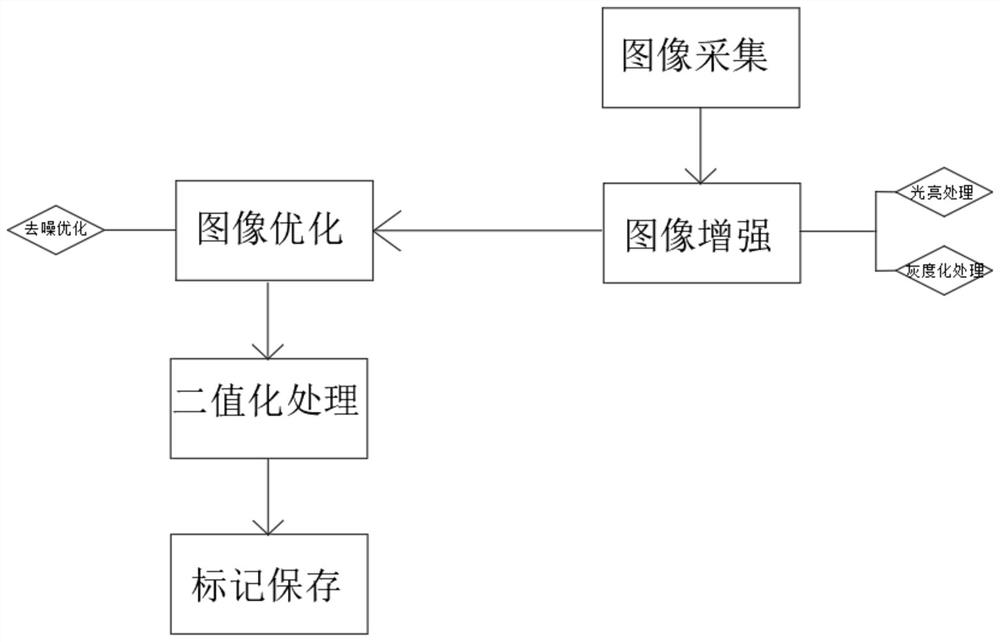

[0038] Such as figure 1 As shown, the embodiment of the present invention provides a machine learning-based small hardware defect detection algorithm, including the following steps:

[0039] Sp1: Image acquisition: select a suitable light source, adjust the distance between the tested fittings and the light source, and collect images of the tested fittings;

[0040] Sp2: Image enhancement: correcting the illumination of the collected image to enhance the collected image;

[0041] Sp3: Image optimization: de-noise the enhanced image, and combine with the 3D block matching algorithm to optimize and de-noise again;

[0042] Sp4: Binarization processing: the processed image is binarized, and the processed image is divided into a spot image and a background image;

[0043] Sp5: mark preservation: compare the detected image with the original image, and carry out mark preservation.

Embodiment 2

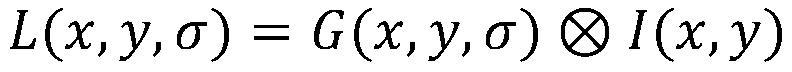

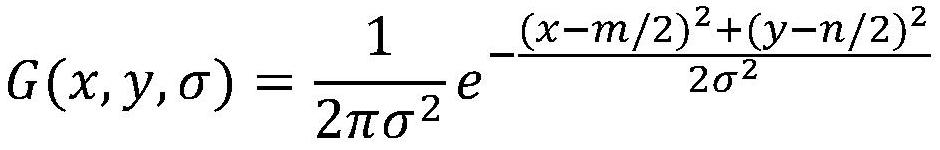

[0045] Such as figure 1 As shown, the secondary light tube is the selected light source, and the secondary light tube is composed of 80-120 light-emitting diodes arranged equally. The light-emitting direction of each secondary tube is 120°. position, the industrial digital camera is the image acquisition device of the tested fittings, which collects the images of the tested fittings, evaluates the light component of the collected image, obtains the expression of the light component, and uses the two-dimensional gamma function to perform automatic calculation according to the distribution characteristics of the light. Adaptive adjustment, and the image is processed by image grayscale to increase the value of the value of the image illumination component after the image is collected, I is the collected image, (x, y) is the coordinate of the image pixel, G(x, y, σ) is a Gaussian function, L(x,y,σ) is the scale space of the image, is the convolution operation;

[0046]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com