Sowing device for seedling raising of early indica rice breeding small material

A seeding device, the technology of early indica rice, applied in the field of seeding device for early indica rice breeding small material seedlings, to achieve the effects of avoiding mixing, improving seeding efficiency, and improving seeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

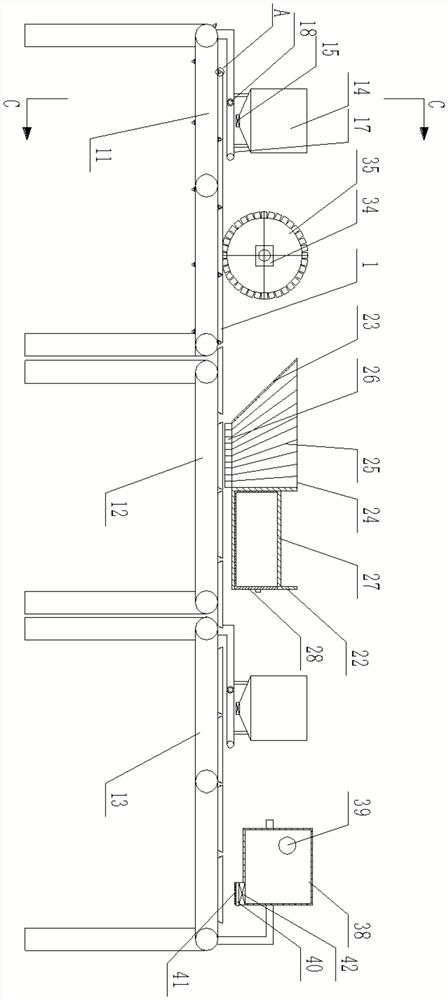

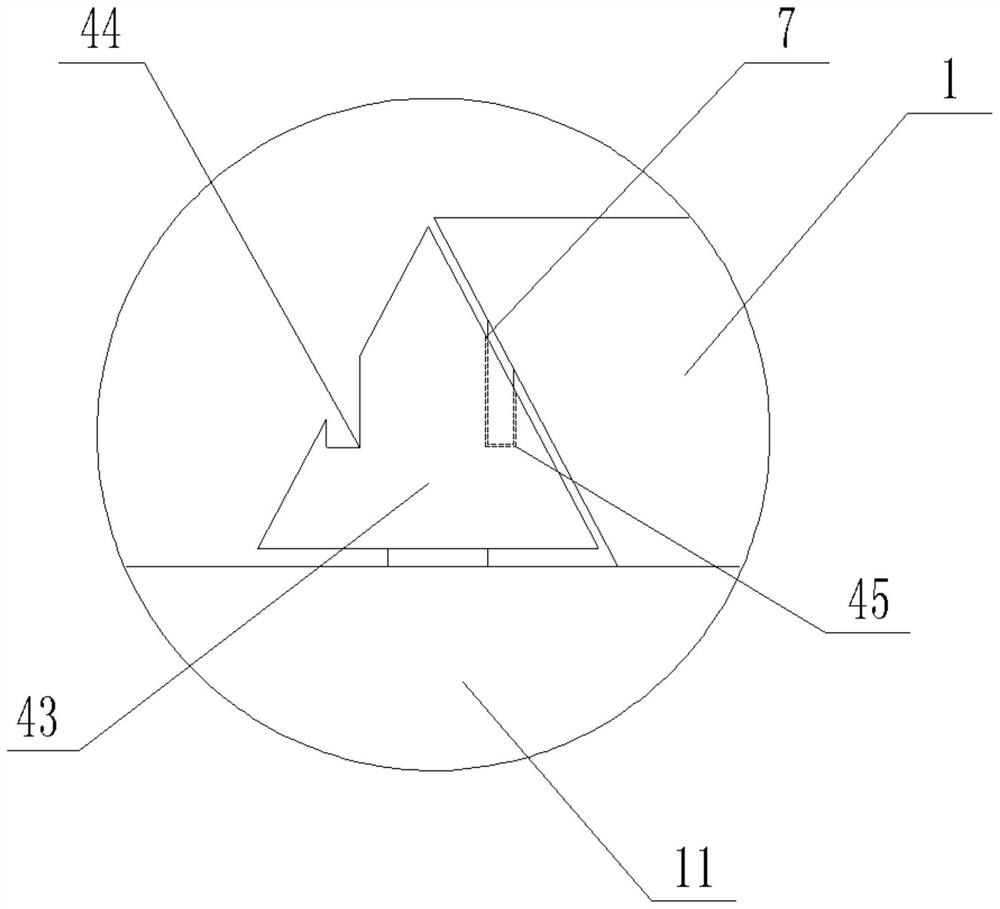

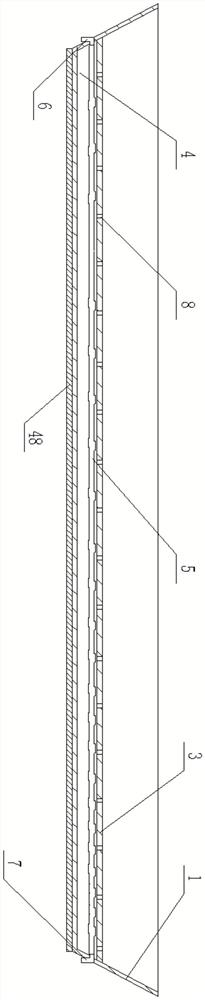

[0043] refer to Figure 1-7 as well as Figure 9 , the present invention provides a kind of sowing device for seedling raising of small materials for early indica rice breeding, comprising a seedling raising tray 1, a transmission mechanism, and a sowing mechanism;

[0044] The inner wall of the seedling-raising tray 1 is detachably connected with several partitions, and the outer wall of the seedling-raising tray 1 is provided with an error-proof component; the partitions divide the interior of the seedling-raising tray 1 into several planting areas. The number of plants and the number of planting plants are placed in a separate planting area in order to avoid mixing;

[0045] The transmission mechanism is installed on the ground through a fixed bracket. The transmission mechanism is used to transmit the seedling raising tray 1. The transmission mechanism is provided with a number of guide components that are detachably connected with the error-proof components. With this ar...

Embodiment 2

[0065] refer to Figure 8 The difference between this embodiment and Embodiment 1 is that the top of the hopper 14 is open, and a mounting plate is fixedly connected to the opening, and a third motor 46 is fixedly installed on the mounting plate, and the output shaft of the third motor 46 is installed through the plate, and is connected with the mounting plate through a bearing, the bottom of the output shaft of the third motor 46 extends into the soil discharge port, and the output shaft of the third motor 46 is fixedly connected with an auger blade 47;

[0066] So set, the third motor 46 drives the auger blade 47 to output the soil in the hopper 14 to the soil conveyor belt 17 while stirring, so as to realize the quantitative discharge of soil, and the control of the discharge speed can be realized by adjusting the rotating speed of the third motor 46, and the operation Convenient and high drainage efficiency.

Embodiment 3

[0068] refer to figure 1 , Figure 9-12 The difference between this embodiment and Embodiment 1 is that a plug-in board is provided on the seedling raising tray 1, and a labeling paper is detachably connected to the plug-in board. In the plug-in board, the labeling of the seedling tray 1 is realized, and the labeling can be changed at will after recycling, and the operation is simple;

[0069] The quantity of movable spacer 10 is preferably 20, and 20 movable spacers 10 and fixed spacer 9 are divided into 20 planting areas in the seedling-raising tray 1 (for example, in No. 1# seedling-raising tray 1, be divided into 1-1, 1 -2, 1-3, 1-4...), the first lead-out pipe 6 is set as the front end of the transportation, the second lead-out pipe 7 is the rear end, and the numbered papers of some seedling raising trays 1 are successively 1#, 2#, 3#, 4#, 5#..., the sequence of 1#-3# seedling tray 1 is as follows Figure 12 In this way, when the same early indica rice species 21 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com