Box type filter

A cartridge filter and filter element technology, applied in membrane filter, fixed filter element filter, filtration separation, etc., can solve the problems of filter medium damage, small mechanical strength, leakage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

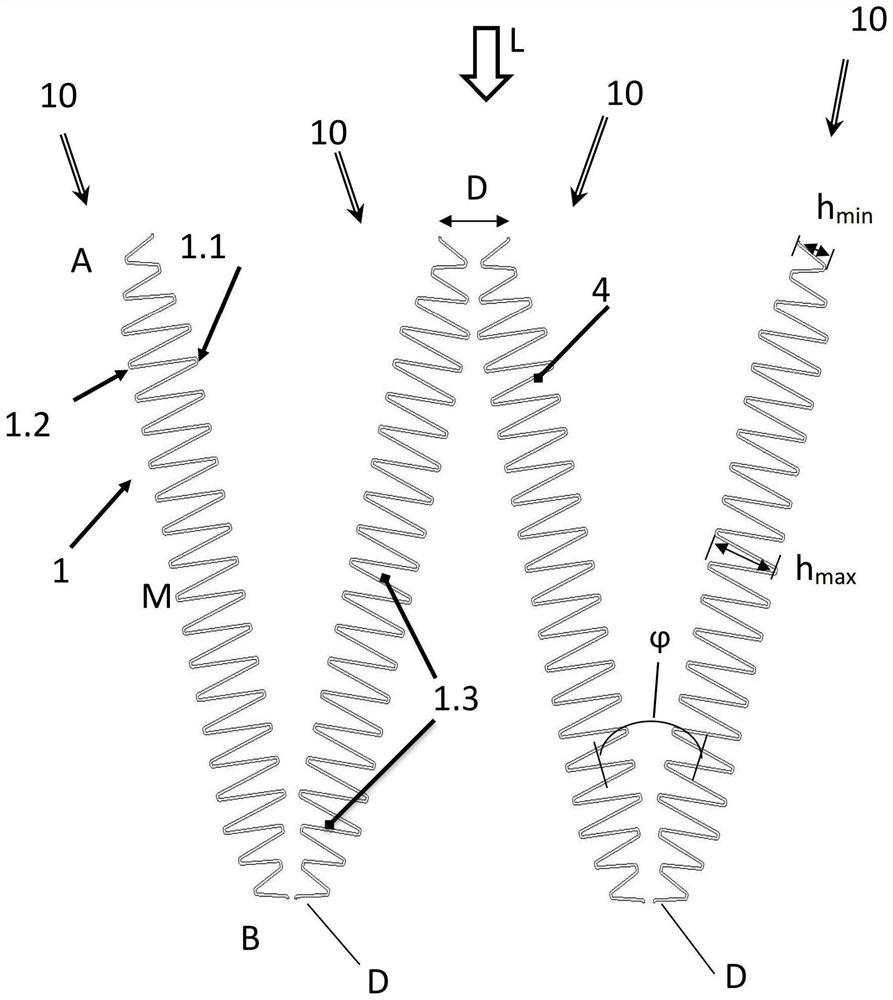

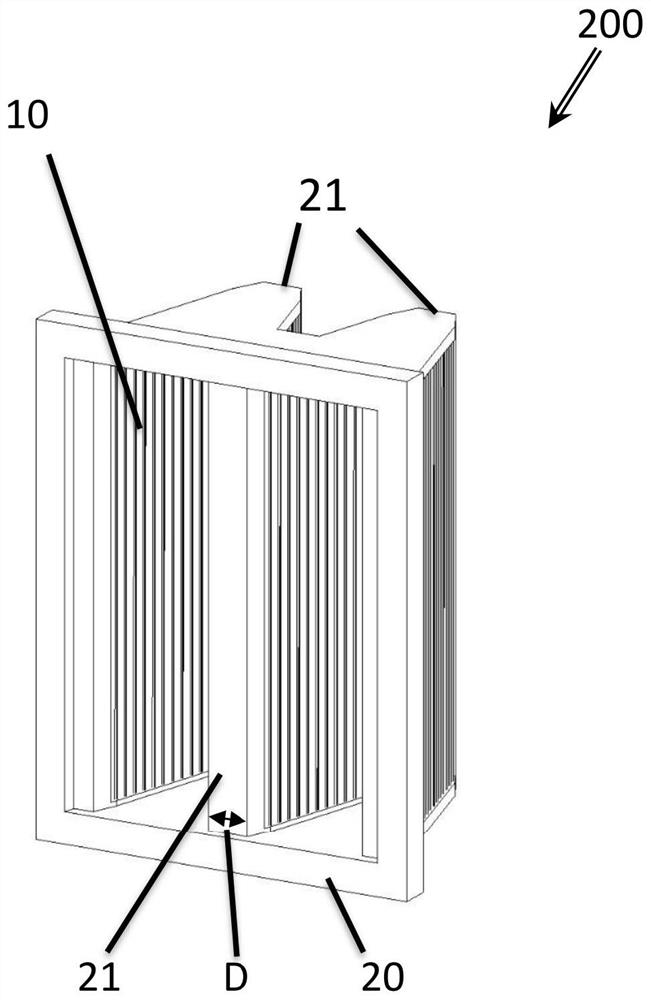

[0026] exist figure 1 Four filter elements 10 for a filter 200 according to the invention are shown in . The corresponding filter element 10 is provided with folded structures 1 on its surface. Compared to known pleated filter elements, the filter medium 4 of the filter element 10 is provided with a special pleated structure 1 .

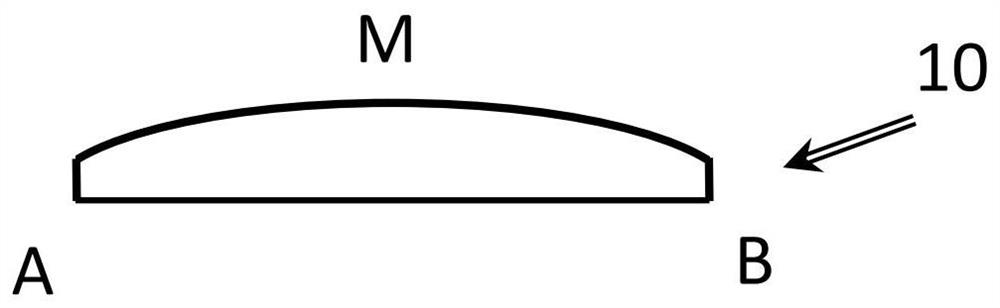

[0027] The filter element 10 has a folded structure 1 forming a plurality of fold peaks 1.1 and a plurality of fold valleys 1.2. Fold structure 1 is not the known notebook fold structure (Leporello-Faltung) or uniform zigzag fold structure (Zick-Zack-Faltung), which are also commonly referred to as pleats And there are rectangular folding sections 1.3 of exactly the same size. In contrast, the fold structure 1 is embodied as a special fold structure 1 , so that fold surfaces or fold sections 1 . 3 of different dimensions are produced. In this case, the folded structure 1 is such that the height h of the filter element in the edge regions A, B mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com