MXene quantum dot sensitized poly (diallyldimethylammonium chloride) modified indium zinc sulfide photocatalyst as well as preparation and application thereof

A technology for sensitizing polydiallyl dimethyl ammonium chloride and photocatalyst, which is applied in the fields of composite materials, photocatalytic technology and sustainable development of environment and energy. To wait for the problem, to achieve the effect of strong cycle stability, low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

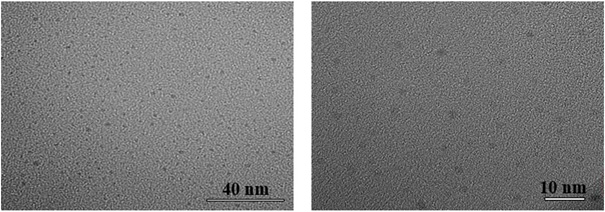

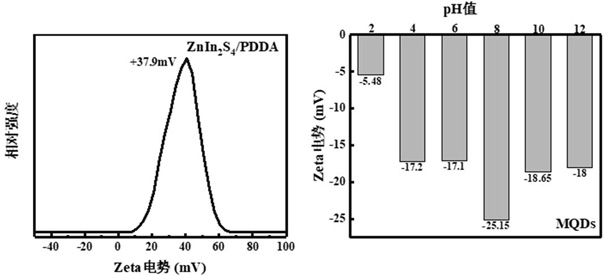

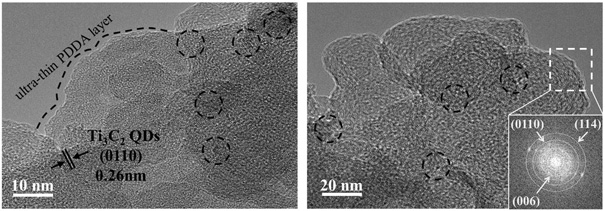

[0028] ①Add 1.5 mmol of Zn(CH 3 COO) 2 2H 2 O and 3 mmol InCl 3 Add 250 mL of deionized water and stir for 30 minutes. Subsequently, excess thioacetamide (TAA, 8 mmol) was added to the above solution and stirred for 30 minutes. The mixed solution was then heated to 95 °C for 5 h with vigorous stirring. After cooling to room temperature, the orange precipitate was collected by centrifugation and washed several times with deionized water to obtain ZnIn 2 S4 Nanosheets.

[0029] ② Dilute 2.0 g of Ti 3 AlC 2 The powder was immersed in 40 mL of 48% hydrofluoric acid and stirred continuously at 60°C for 20 hours. The obtained powder was then washed several times with deionized water, centrifuged at 3500 rpm for 10 min to recover the powder particles, and dried under vacuum at 60 °C. The obtained powder was then placed in 80 mL of deionized water, and ultrasonicated for 30 minutes under nitrogen protection. The pH of the mixed solution was adjusted to 9 with ammonia water, ...

Embodiment 2

[0034] ①Add 1.5 mmol of Zn(CH 3 COO) 2 2H 2 O and 3 mmol InCl 3 Add 250 mL of deionized water and stir for 30 minutes. Subsequently, excess thioacetamide (TAA, 8mmol) was added to the above solution and stirred for 30 minutes. Then the mixed solution was heated to 95 °C for 5 h with vigorous stirring. After cooling to room temperature, the orange precipitate was collected by centrifugation and washed several times with deionized water to obtain ZnIn 2 S 4 Nanosheets.

[0035] ②Add 2.0g Ti 3 AlC 2 The powder was immersed in 40 mL of 48% hydrofluoric acid and stirred continuously at 60°C for 20 hours. Then the obtained powder was washed several times with deionized water, centrifuged at 3500 rpm for 10 minutes to recover the powder particles, and dried under vacuum at 60 °C. The obtained powder was then placed in 80 mL of deionized water, and ultrasonicated for 30 minutes under nitrogen protection. The pH of the mixed solution was adjusted to 9 with ammonia water, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap