Slit coating die head

A technology of slit coating and die head, which is applied to the device and coating of the surface coating liquid, which can solve the problems of holes and uneven thickness of the film, achieve efficient elimination, solve the problem of holes in the film, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

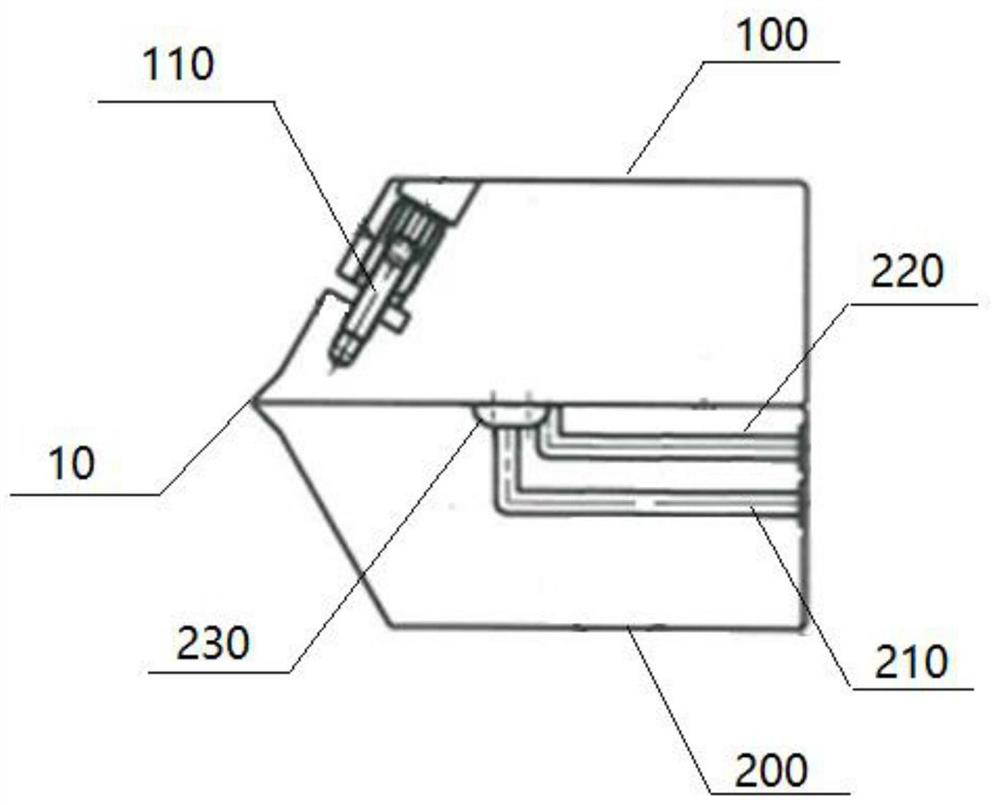

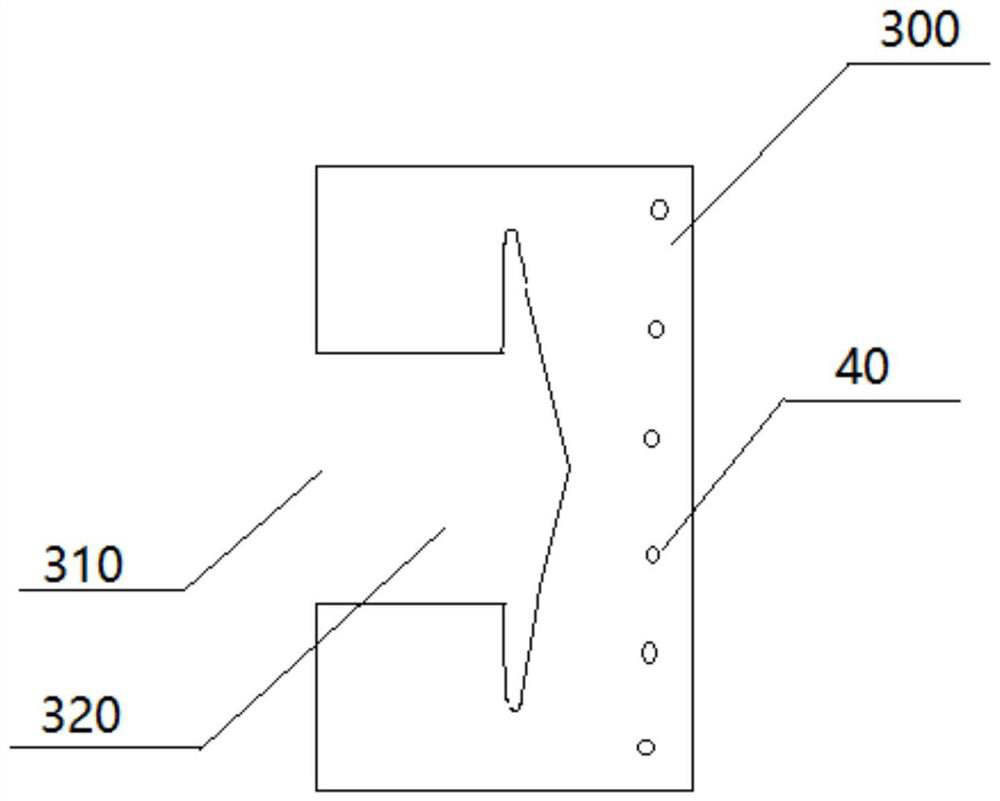

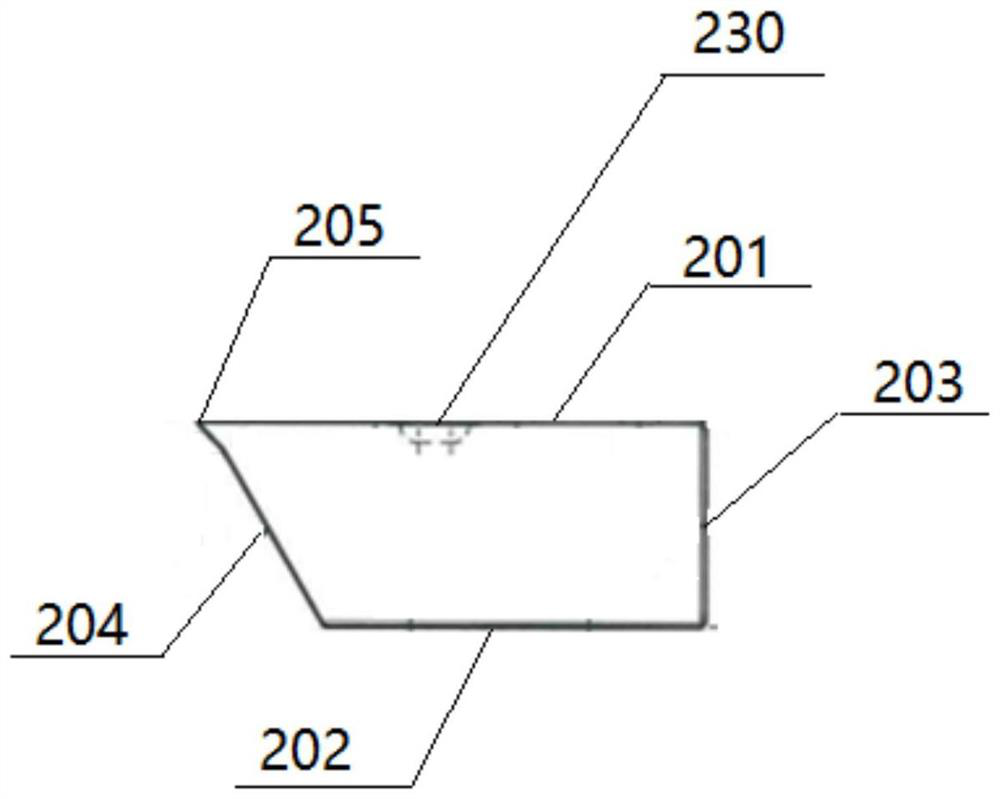

[0067] figure 1 It is a schematic diagram of a section of a slot coating die of the present invention. figure 2 It is a schematic diagram of a gasket of a slot coating die of the present invention. image 3 It is a schematic side view of the lower die of a slit coating die of the present invention. Figure 4 It is a schematic front view of a slit coating die of the present invention.

[0068] Such as Figure 1 ~ Figure 4 As shown, the slot coating die head includes an upper die 100 , a lower die 200 , a gasket 300 between the upper die 100 and the lower die 200 and a two-way switch.

[0069] The lower mold 200 is provided with at least one feed channel 210 , at least one exhaust channel 220 and a material cavity 230 . The exhaust channel 220 is located above the feed channel 210 . The exhaust passage 220 and the feed passage 210 communicate with the material chamber 230 respectively. The feeding channel 210 is used for feeding the coating liquid. The exhaust channel 22...

Embodiment 2

[0080] Except following structure, all the other are identical with embodiment 1:

[0081] Slot dies also include connection blocks and adapters. The connection block is disposed on the positioning and fastening surface 203 , and the connection block is provided with connection holes corresponding to the feed hole 211 and the exhaust hole 221 . The conversion joints are respectively arranged on the connection holes. The two-way switch is connected with the conversion joint corresponding to the exhaust hole, and is used for controlling the opening and closing of the exhaust passage 220 .

Embodiment 3

[0083] Except following structure, all the other are identical with embodiment 2:

[0084] The slit coating die head also includes buckles and beading. Buckles are respectively provided on the first side and the second side of the upper mold 100 and the lower mold 200 . The bead is arranged between the buckle and the first side, and the bead is also arranged between the buckle and the second side, for sealing both sides of the outlet 10 of the slit channel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com