High-precision oil-electric hybrid electro-hydraulic servo numerical control bending machine

An electro-hydraulic servo and bending machine technology, applied in the field of CNC bending machines, can solve the problems of ordinary hydraulic systems such as large noise, long time spent, and low energy utilization, and achieve accuracy and applicability. Strong, comprehensive practicality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

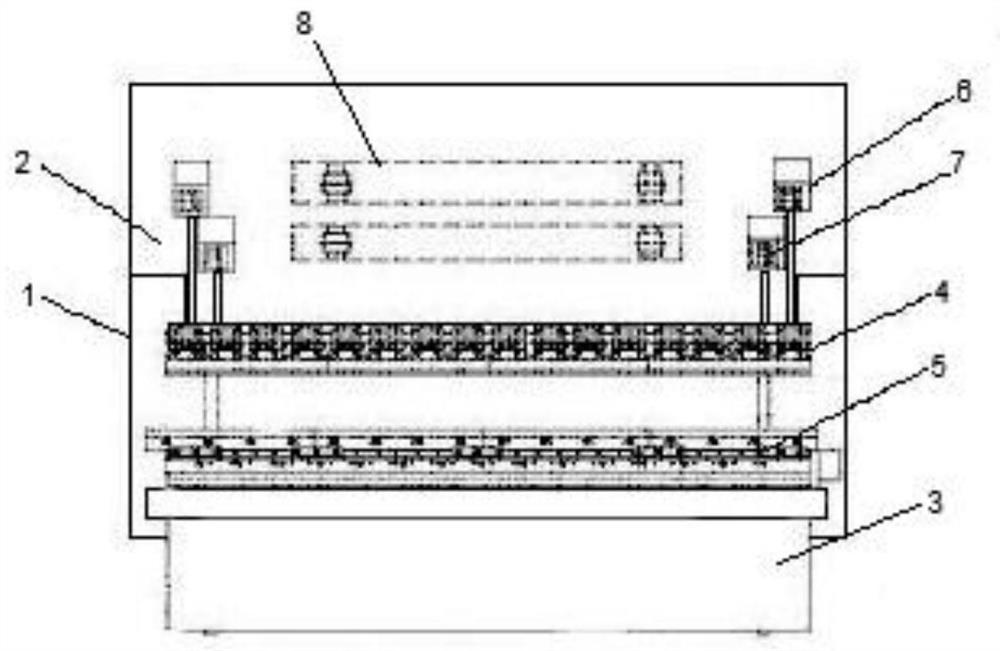

[0037] A high-precision oil-electric hybrid electro-hydraulic servo CNC bending machine, comprising a bending machine body 1, a movable mounting plate 2 is slidably connected to the upper part of the front side of the bending machine body 1, and a worktable is arranged at the lower part of the front side of the bending machine body 1 3. The upper die 4 and the lower die 5 are respectively installed on the movable mounting plate 2 and the worktable 3. The upper die 4 is connected with a tool for bending, and the lower die 5 is connected with a positioning tool suitable for the bending tool. groove;

[0038] The body 1 of the bending machine is equipped with a multiple drive device for driving the upper die 4 to move up and down. The multiple drive device includes a first oil cylinder 6 and a second oil cylinder 7. The output ends of the first oil cylinder 6 and the second oil cylinder 7 are connected by oil pipes The output rod, which is connected with the upper die 4, is used ...

Embodiment 2

[0045] Based on the oil-electric hybrid electro-hydraulic servo CNC bending machine proposed in Example 1, further,

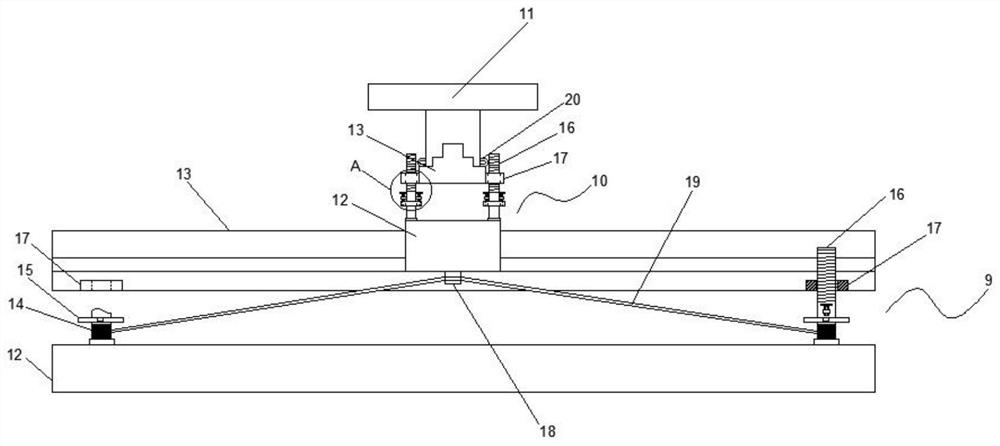

[0046] The rear side of the bending machine body 1 is installed with a material stopper mechanism, including a first linear guide rail 9 arranged along the depth direction of the bending machine body 1, and a second linear guide rail 10 arranged along the length direction. On the worktable 3, the second linear guide rail 10 is slidably arranged on the first linear guide rail 9, and the second linear guide rail 10 is slidably provided with a stopper platform 11 for the interference support of the workpiece.

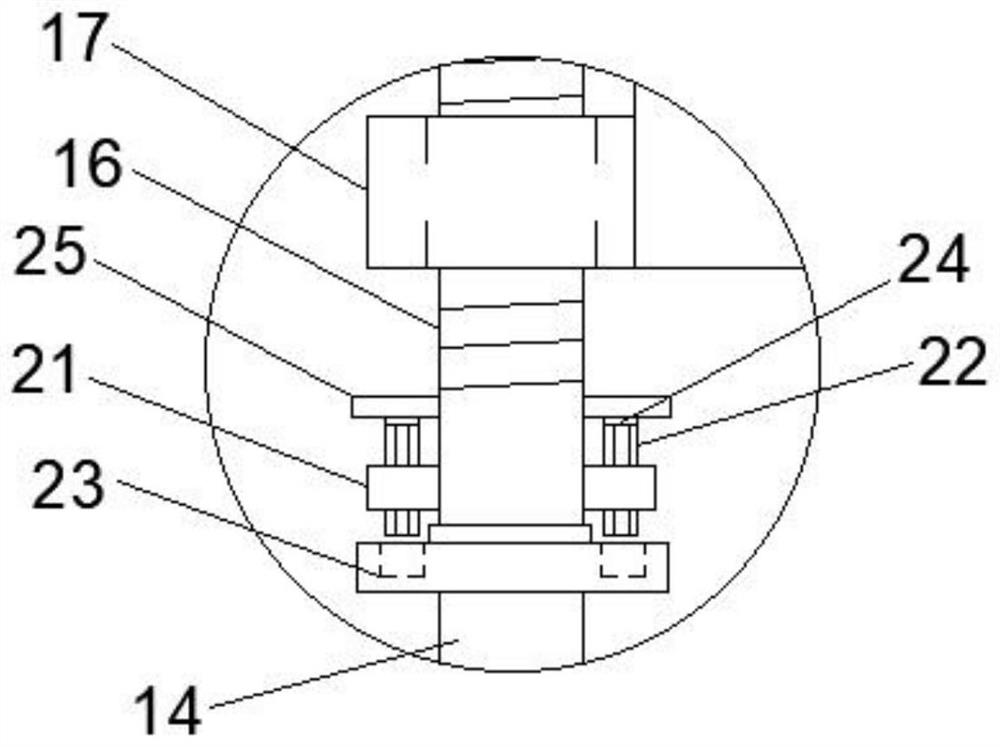

[0047] Further, the first linear guide rail 9 and the second linear guide rail 10 are composed of a base plate 12 and a slide rail plate 13. A shaft column 14 is rotatably installed around the top of the base plate 12, and the upper end of the shaft column 14 is provided with a top plate 15. The top plate 15 The upper end is rotatably installed with a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com