Metal component 3D printing device and method under microgravity environment

A metal component, 3D printing technology, applied in the field of 3D printing, can solve the problems that cannot be directly applied to the field of 3D printing in space, cannot effectively realize microgravity vacuum forming, and the phenomenon of gas thermal convection failure, etc., to improve the forming efficiency and forming accuracy. , the structure is simple, the effect of feedback is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

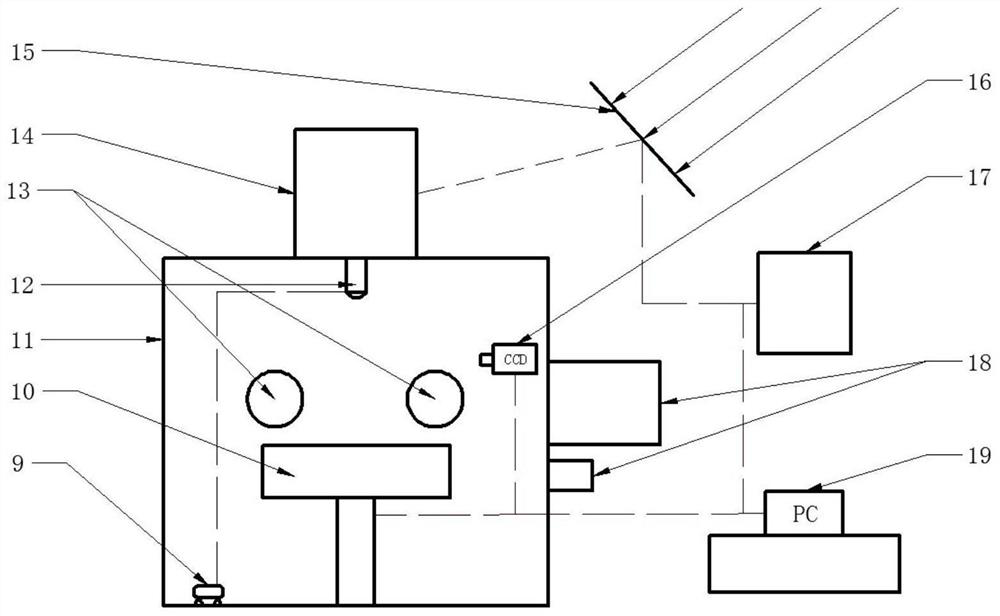

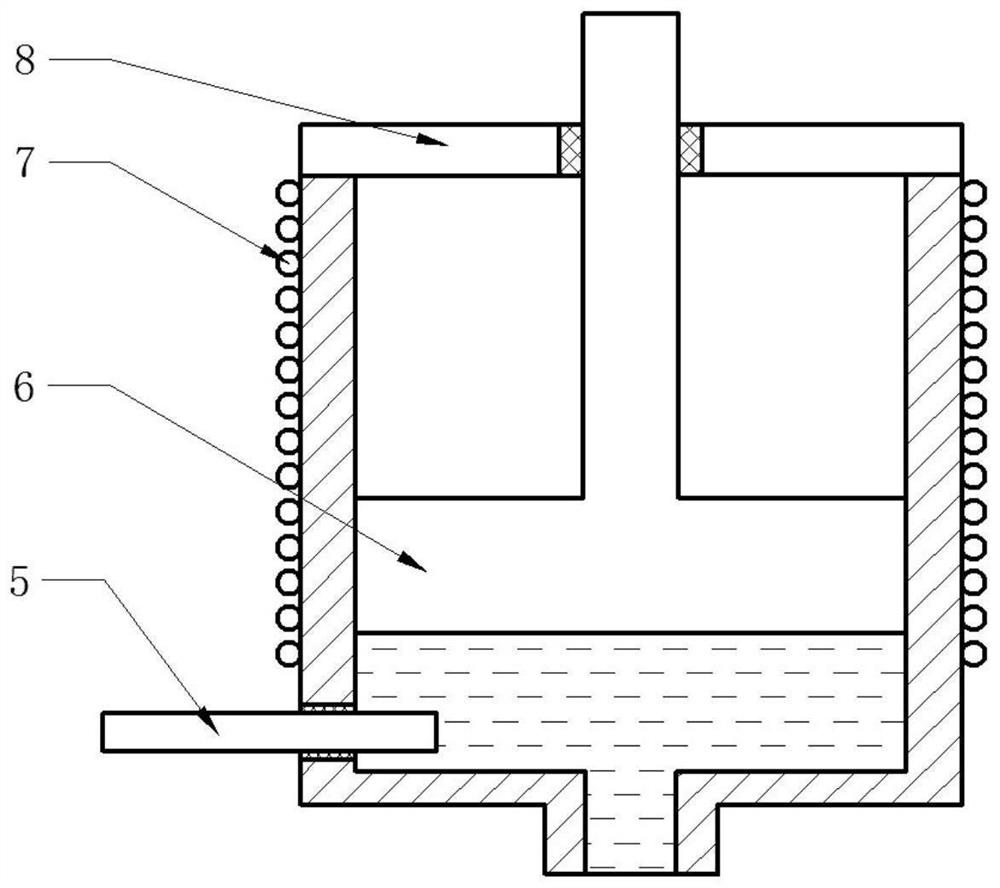

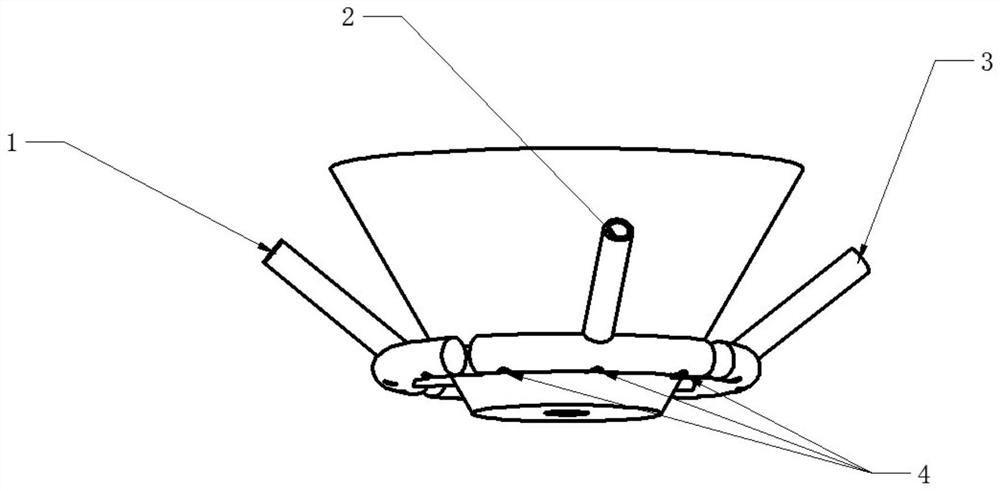

[0030] Such as figure 1 As shown, a metal component 3D printing device in a microgravity environment includes a sealed forming cavity 11, a metal melting unit 14 is installed on the top of the sealed forming cavity 11, and the printing nozzle 12 of the metal melting unit 14 is located in the sealed forming cavity 11 Inside, the sealed forming cavity 11 is provided with a translation platform 10 and a graphics acquisition device 16, the translation platform 10 is located below the printing nozzle 12, and the graphics acquisition device 16 is used to obtain the forming image on the translation platform 10, and the outer ring of the printing nozzle 12 is provided with Cooling device, the side wall of the sealed forming cavity 11 is provided with a pick-up bin 18 . In this application, the sealing and forming cavity 11 is used to form a printing sealing cavity, and a cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com