Novel water-cooling welding gun

A water cooling and welding torch technology, applied in welding accessories, welding rod characteristics, welding equipment, etc., can solve the problem of poor nozzle cooling effect and other problems, and achieve the effect of ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention are clearly and completely described below.

[0035] Embodiments of the invention:

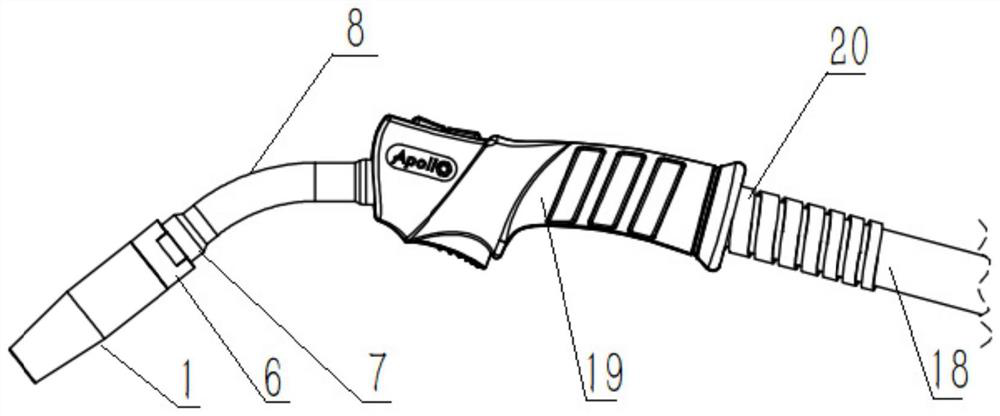

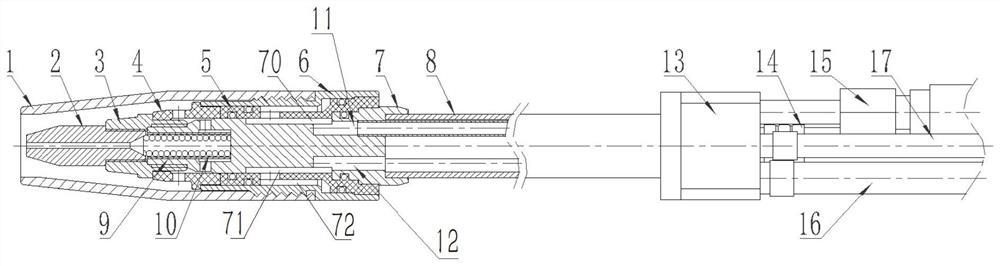

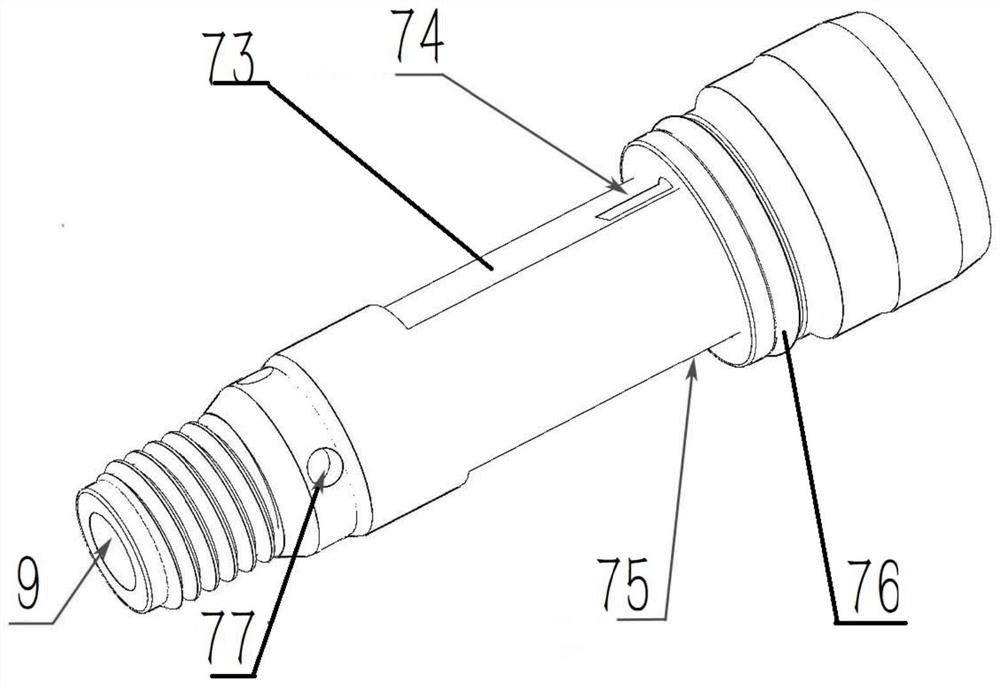

[0036] Such as Figure 1-2 As shown, a new type of water-cooled welding torch includes a gun nozzle 1, a conductive tip 2, a conductive tip seat 3, a water cooling jacket 5, a nozzle seat 6, a neck seat 7, a torch neck outer tube 8, a gun cable outer tube 18, a handle 19, And spiral steel belt protective cover 20.

[0037] The end of the welding workpiece in the welding torch is set as the left end, and this is used as the direction reference for the description.

[0038] The water cooling jacket 5 is set on the gun neck seat 7, the nozzle seat 6 is set on the water cooling jacket 5, the nozzle 1 is set on the nozzle seat 6, the conductive tip seat 3 is set on the left end of the gun neck seat 7, and the conductive tip 2 is connected On the contact tip seat 3, the contact tip 2 is located at the inside of the nozzle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap