Intelligent laser edge trimmer and edge trimming process

An edge trimmer and laser cutting technology, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of low casting quality and processing efficiency, cutting product safety, and inability to deal with abnormal shapes, etc., to achieve improved processing Effect quality and efficiency, reduce the initial investment cost, improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The application will be described in further detail below in conjunction with the accompanying drawings.

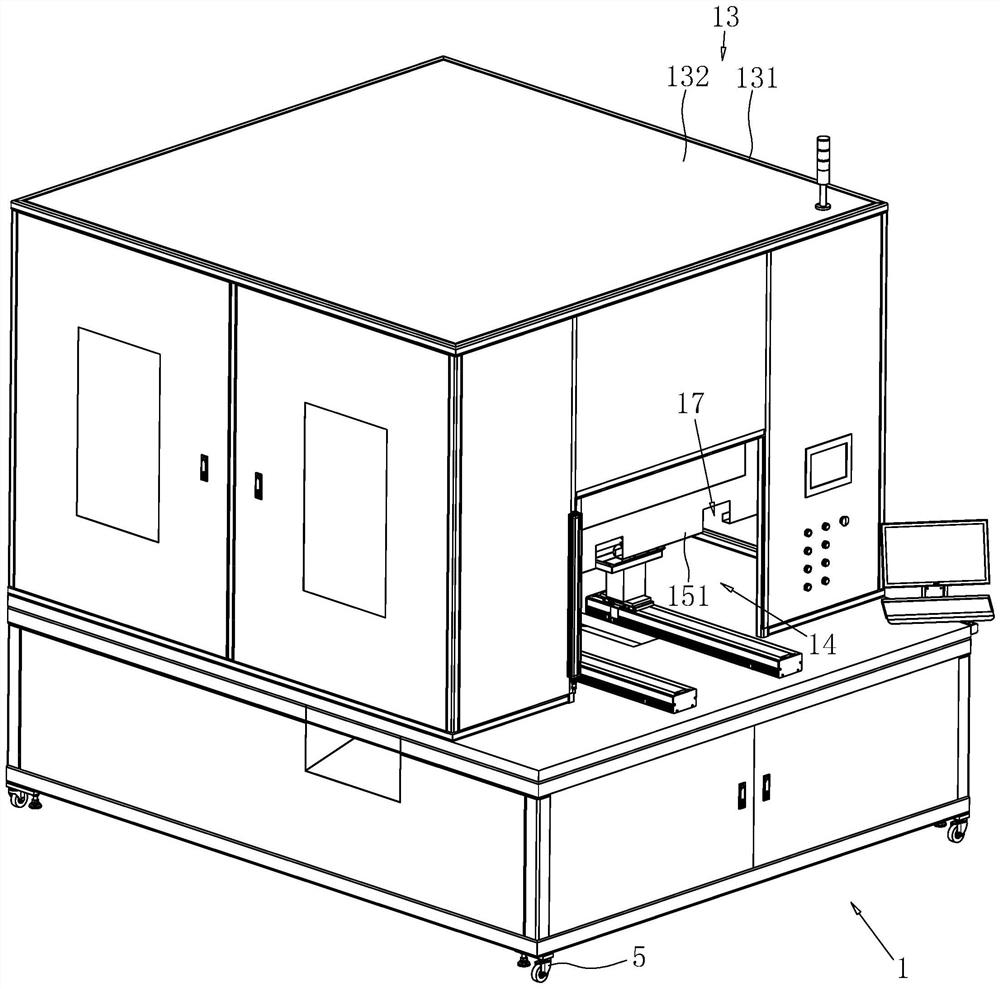

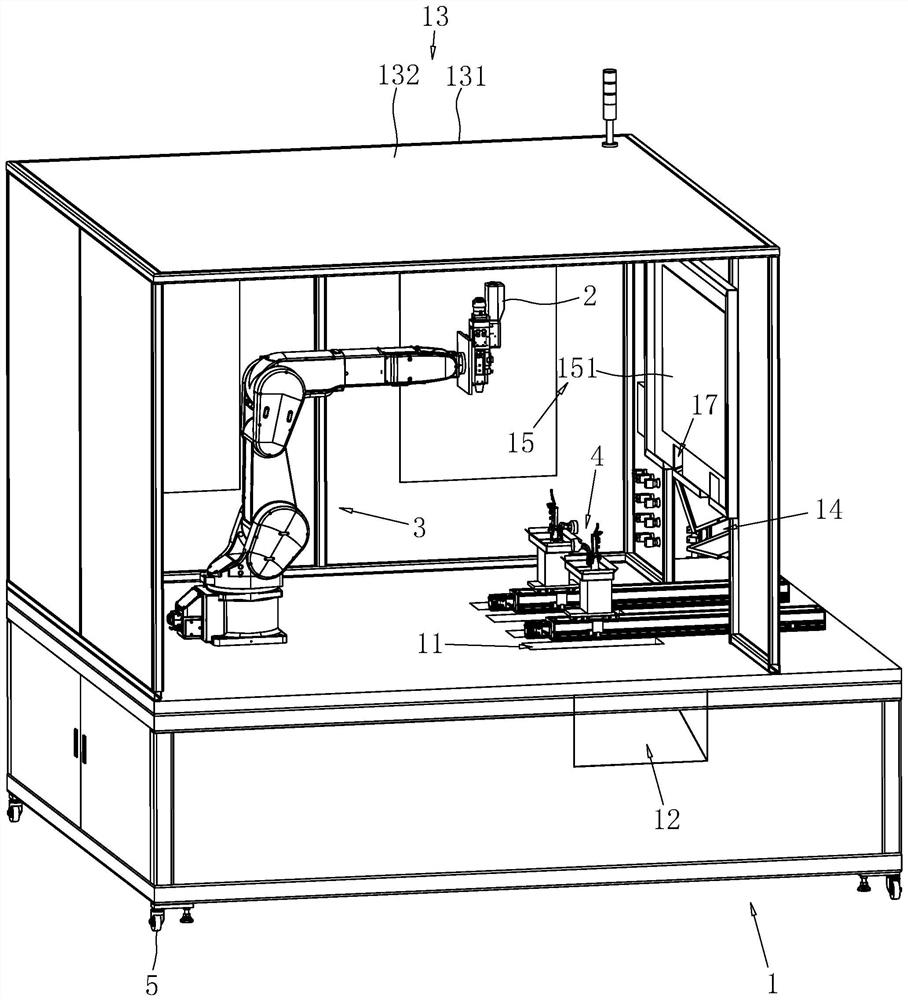

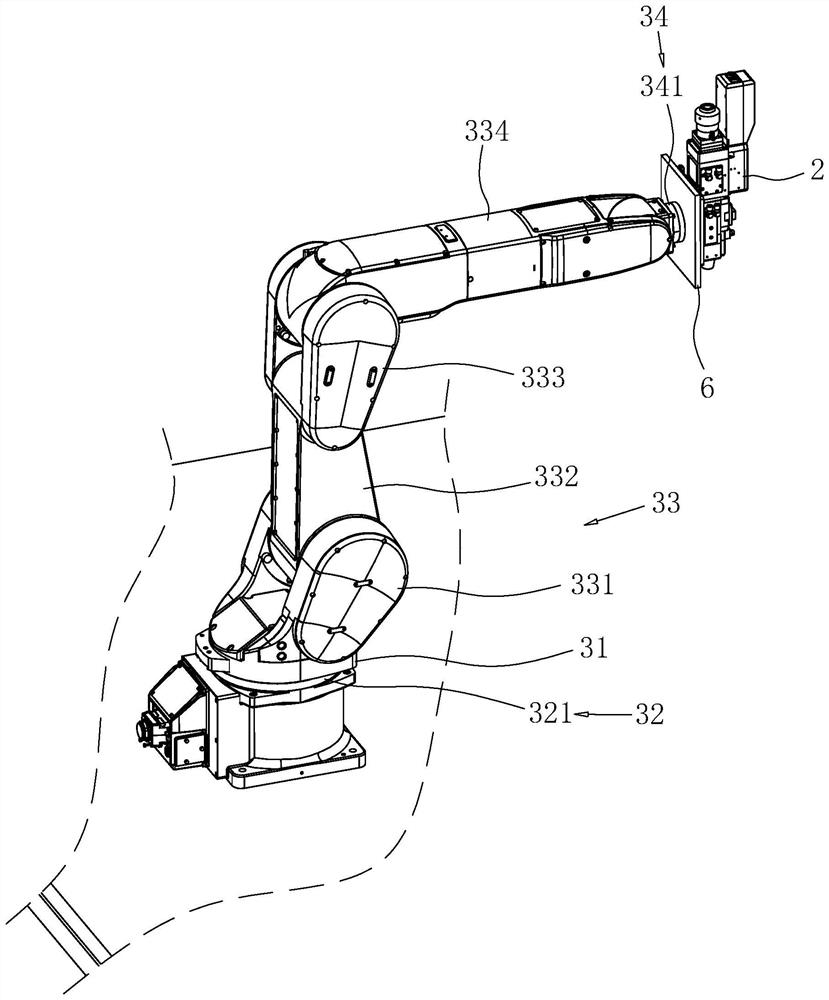

[0037] The embodiment of the present application discloses an intelligent laser edge trimmer. refer to figure 1 with figure 2 , the intelligent laser edge trimming machine includes a body 1, on which a laser cutting knife 2 for cutting 8 scraps of castings is arranged. The laser cutting knife 2 is a known technology, and will not be introduced here. The activity is arranged on the body 1, and the body 1 is provided with a driving device 3 for driving the laser cutting knife 2; the body 1 is provided with a fixing device 4 for fixing the casting 8; for the convenience of adjusting the position of the body 1, the body 1 The bottom is provided with universal wheel 5.

[0038] When processing the casting 8, the casting 8 is fixed on the machine body 1 through the fixing device 4 first, and then the laser cutting knife 2 is driven by the driving device 3 to cut the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com