Reciprocating piston type compressor

A technology of reciprocating pistons and compressors, which is applied in piston pumps, liquid displacement machinery, mechanical equipment, etc., and can solve the problems of large volume of reciprocating piston compressors, difficulty in carrying and storing, poor use of compressors, and gas compression degree Insufficient and other problems, to achieve good work efficiency, good air tightness, large gas compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

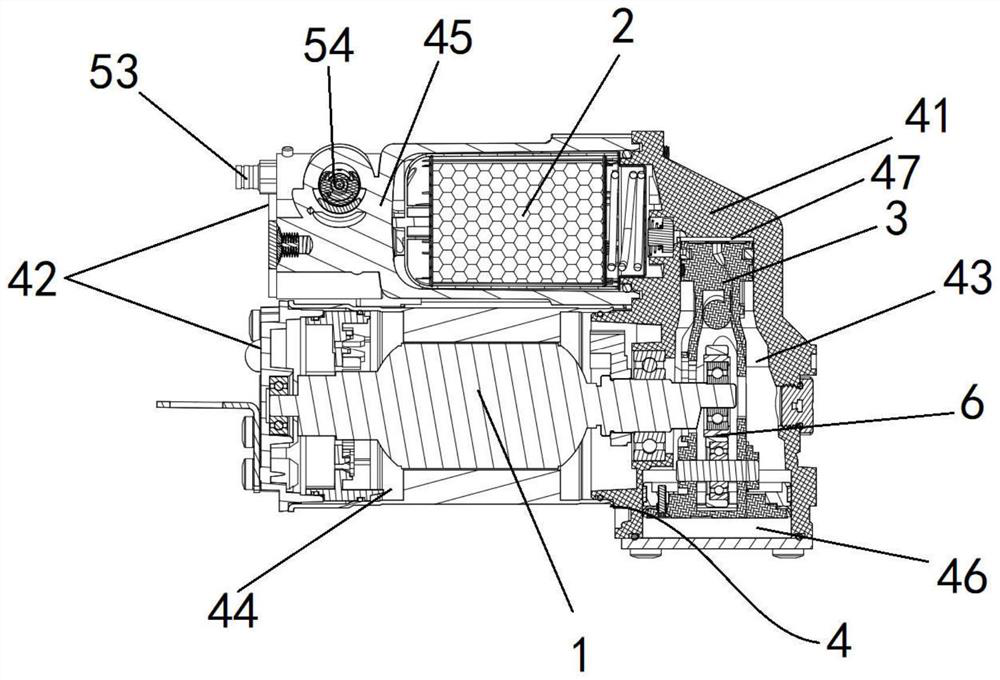

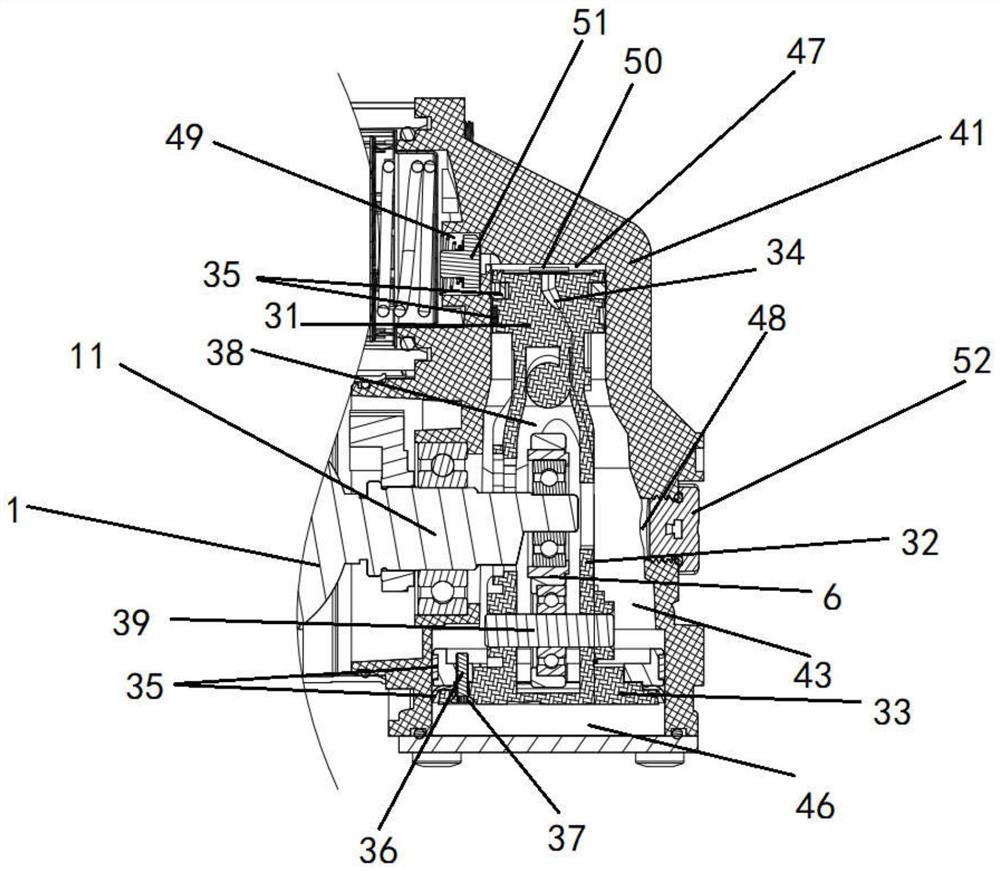

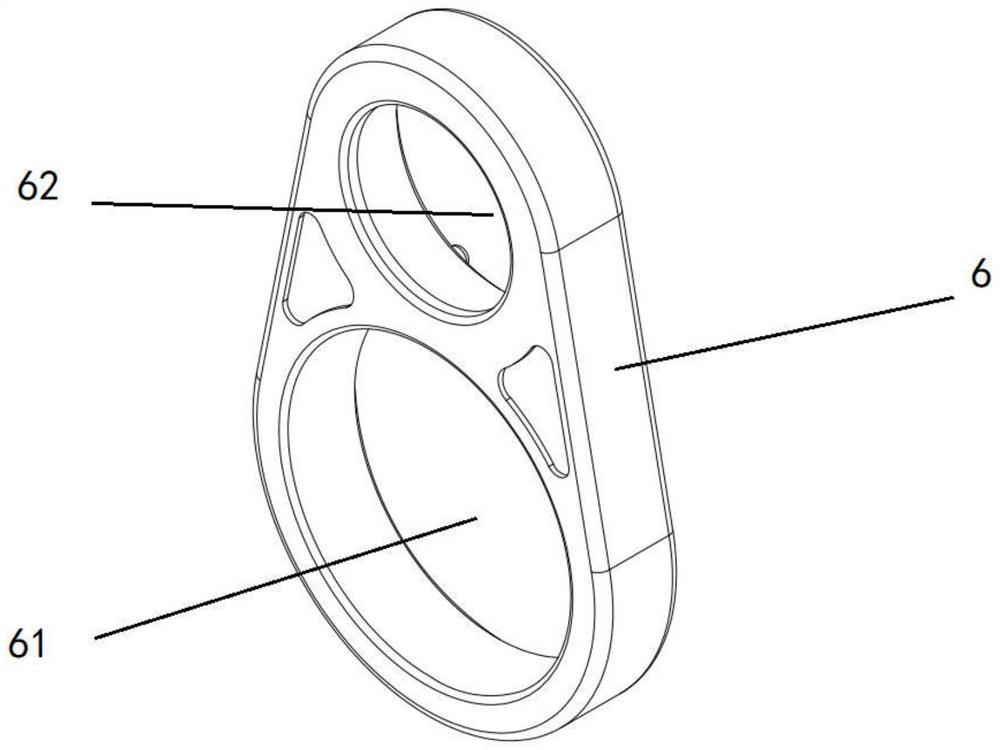

[0035] like Figure 1-6 As shown, a reciprocating piston 3 type compressor includes an eccentric motor 1, a dryer 2, a piston 3 and a compressor housing 4; the compressor housing 4 includes a compression cylinder 41 and an assembly housing 42, and the compression housing The body is provided with a compression space 43, and the assembly housing 42 is provided with a motor assembly space 44 and an exhaust space 45; the eccentric motor 1 is provided in the motor assembly space 44, and the piston 3 is provided in the compression space 43 for reciprocating motion. The dryer 2 It is arranged in the exhaust space 45; the motor assembly space 44 and the exhaust space 45 communicate with the compression space 43 respectively, and the eccentric shaft 11 of the eccentric motor 1 enters the compression space 43 and is connected with the piston 3; the piston 3 includes a piston head 31, a piston Connecting rod 32 and piston base 33, described piston head 31 and piston base 33 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com