Shock absorption and noise reduction mechanism of water feeding pump

A technology for water supply pumps and noise reduction, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids. It can solve problems such as sound pollution and high noise of water pumps, so as to prolong the service life and reduce rigid impact. and friction, improving the efficiency of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

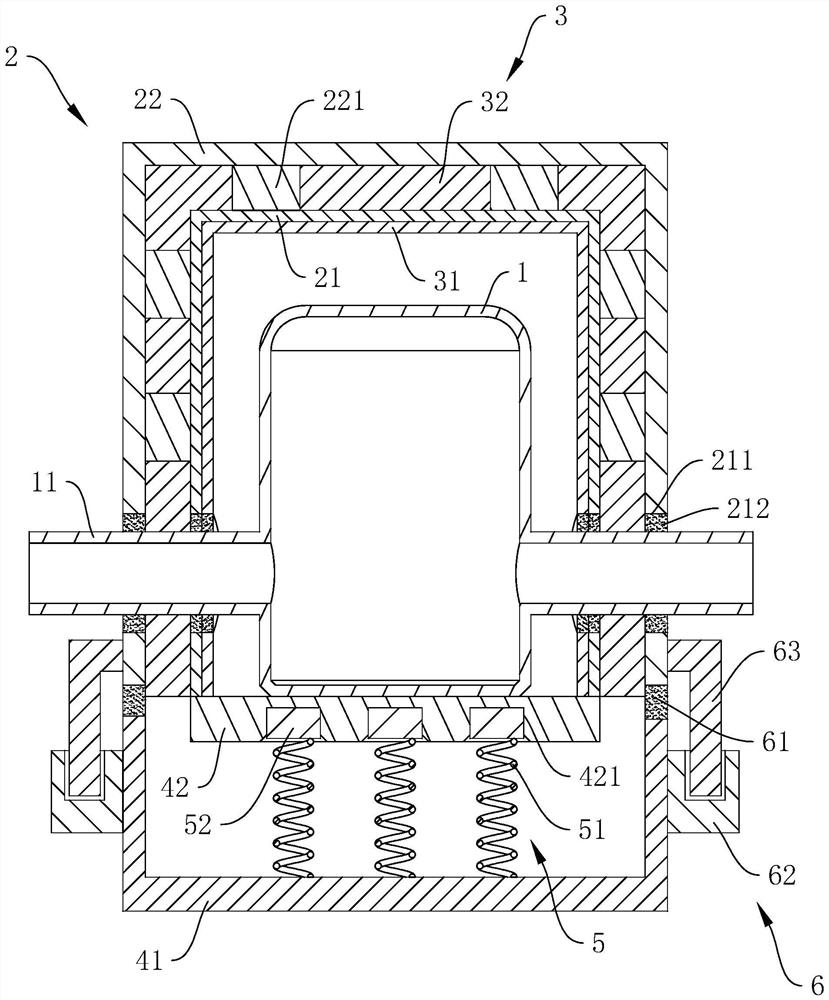

[0034] Contraction below figure 1 Further detailed description of the present application.

[0035] The present application example discloses a shock absorbing noise reduction mechanism for a water pump.

[0036] A shock absorbing mechanism of a water pump includes a housing 2 disposed on the pump body 1 and the lower opening, and both the pump body 1 are connected to the water pump 11, and the housing 2 is opened on both sides of the casing. The perforation 211 passes through the water pipe 11, and the housing 2 is provided with an acoustic wave diffused from the sound wave generated by the pump body 1, and the pump body 1 is provided with a base 4, and the pump body 1 and the housing 2 are mounted. On the base 4, a damper body 1 is provided between the pump body 1 to a buffer shock absorbing action between the pump body 1 and the base 4.

[0037] The pump body 1 generates a vibration at operation, and the damper assembly 5 functions on the pump body 1 to reduce the noise generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com