Groove type heat collection field oil injection adjusting system and oil temperature adjusting method

A technology of regulating system and regulating method, which is applied to solar heating systems, solar collectors, solar collector controllers, etc., can solve problems such as difficulty in regulating the temperature of the hot oil outlet, difficulty in balancing the flow of branches, and ineffective utilization. , to reduce the risk of local medium overheating, increase the utilization rate of new energy, and slow down the rate of deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

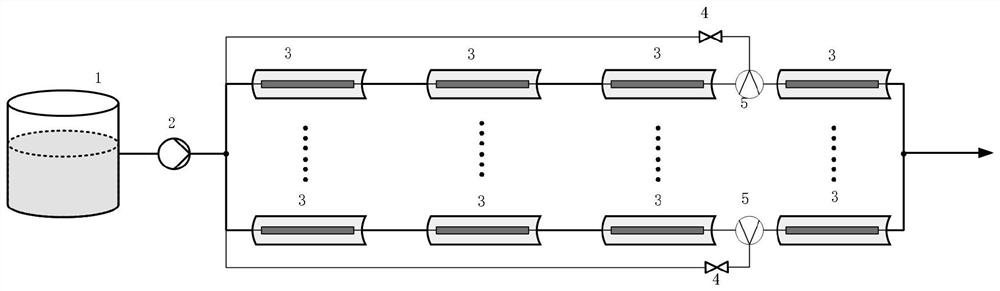

[0025] figure 1 It is the embodiment 1 of a trough heat collecting field fuel injection regulation system. The system includes an oil tank 1, an oil pump 2, a heat collector 3, a flow regulating valve 4, an injector 5, and corresponding pipelines and auxiliary equipment.

[0026] The oil tank 1 and the oil pump 2 are connected through pipelines, and multiple heat collectors 3 are connected in series to form branches. After multiple branches are connected in parallel, the oil pump 2 is connected to each branch in parallel through pipelines; The heat transfer oil flows through all the heat collectors in the branch in sequence. There are multiple branches connected in parallel in the heat collection field. Thermal field; the pipeline at the outlet of the oil pump 2 is connected to the flow regulating valve 4 through a separate pipeline; the flow regulating valve 4 is connected to the fuel injector 5 through a pipeline; the fuel injector 5 is installed at the connection between t...

Embodiment 2

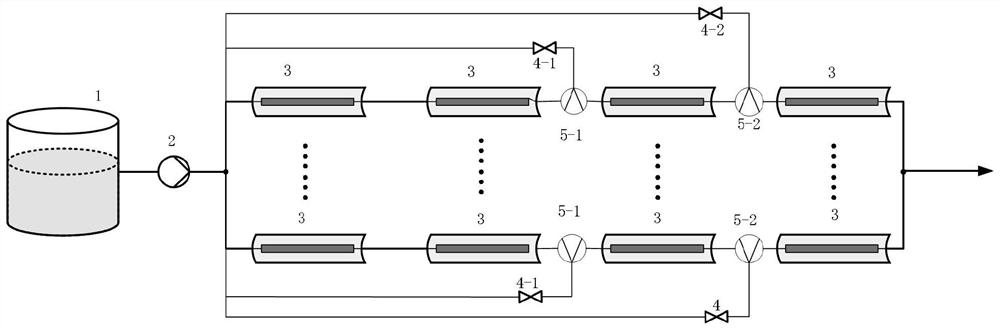

[0031] figure 2 It is the embodiment 2 of the oil temperature regulating method of the trough heat collecting field fuel injection system. The system includes a fuel tank (1), an oil pump 2, a heat collector 3, a primary flow regulating valve 4-1, a primary fuel injector 5-1, a secondary flow regulating valve 4-2, and a secondary fuel injector 5- 2 and the corresponding pipelines and ancillary equipment.

[0032] The oil tank 1 is connected to the oil pump 2 through pipelines, and multiple heat collectors 3 in series form a branch circuit, and the heat transfer oil flows through all the heat collectors in the branch circuit in sequence. The heat conduction oil in the branch circuit is heated by the branch circuit of the heat collector and then gathers in the pipeline to flow out of the heat collecting field; the oil pump 2 is connected to the parallel branch circuit through the pipeline; the pipeline at the outlet of the oil pump 2 is connected with the primary flow regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com