Method for arranging microwave emitters on outer peripheral surface of rotary kiln body

A microwave transmitter and microwave generator technology, which is applied in the direction of rotary drum furnace, lighting and heating equipment, electric furnace heating, etc., can solve the problem of low thermal efficiency utilization rate of microwave generator, unsuccinct thermal efficiency, unreasonable position setting and line direction and other problems, to achieve the effect of simple and orderly layout, improve thermal efficiency utilization, and avoid injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

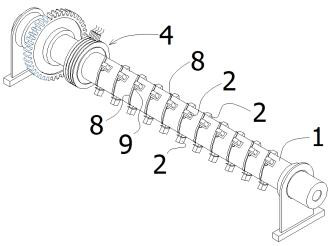

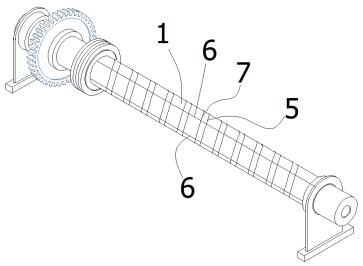

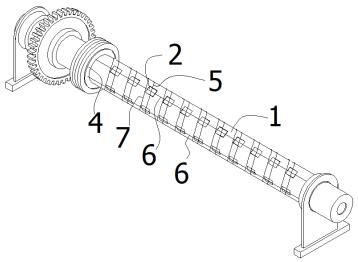

[0030] Such as figure 1 , 3 As shown, a method of arranging a microwave transmitter on the peripheral surface of a rotary kiln body is to arrange a plurality of wave feed ports 2 on the outer peripheral surface of a cylindrical kiln body 1, and to install wave feed ports 2 on each wave feed port 2 that can follow the kiln The microwave generator 3 that the body 1 rotates is set on the kiln body 1 at the same time, the power receiving device 4 that can accept the external power supply under the working condition of the kiln body rotating, and the power line connecting the power receiving device 4 and the microwave generator. The power line is a general term for one neutral line and one to three live lines. In this case, the power cord includes a neutral wire and three live wires. In this way, by installing the microwave generator 3 directly on the wave fee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap