Rescheduling method for flexible job shop

A flexible operation and rescheduling technology, applied in control/adjustment systems, instruments, comprehensive factory control, etc., can solve problems such as untimely scheduling of flexible operation workshops, and achieve the effect of accurate selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The technical scheme that the present invention solves the problems of the technologies described above is as follows:

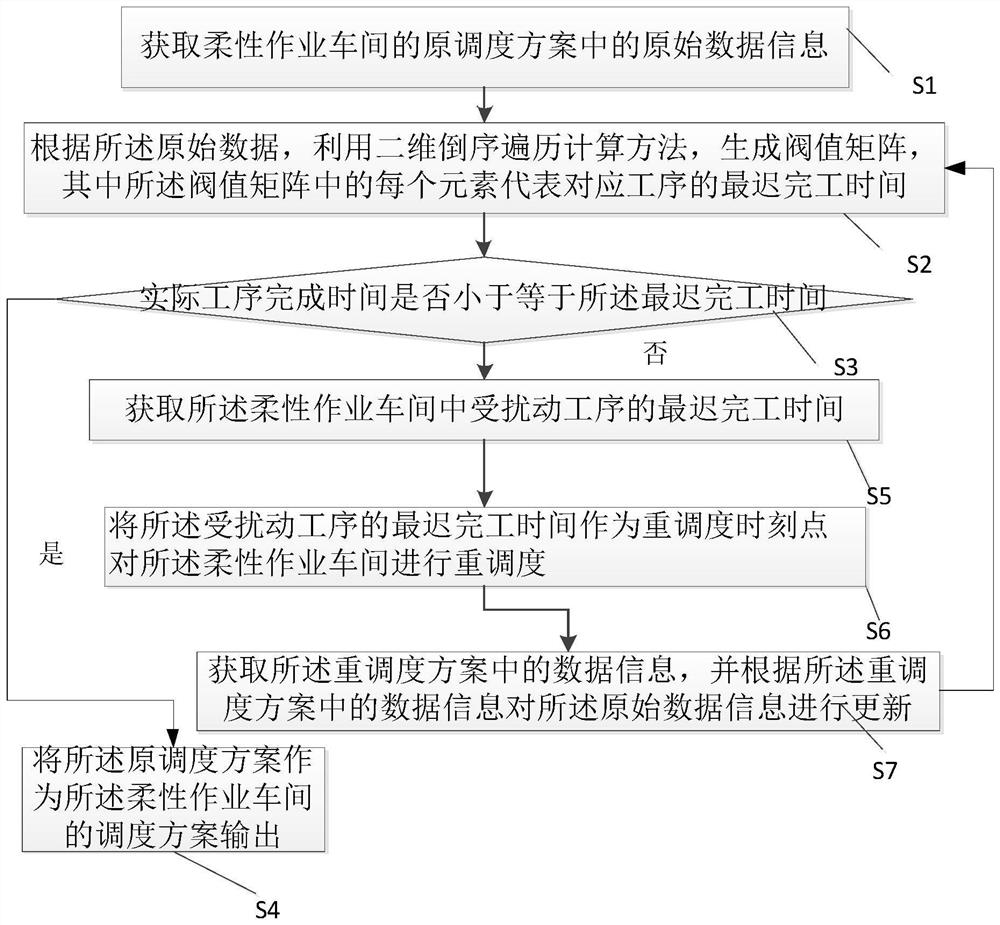

[0056] The present invention provides a rescheduling method for a flexible job shop, referring to figure 1 As shown, the rescheduling method includes:

[0057] S1: Obtain the original data information in the original scheduling plan of the flexible job shop;

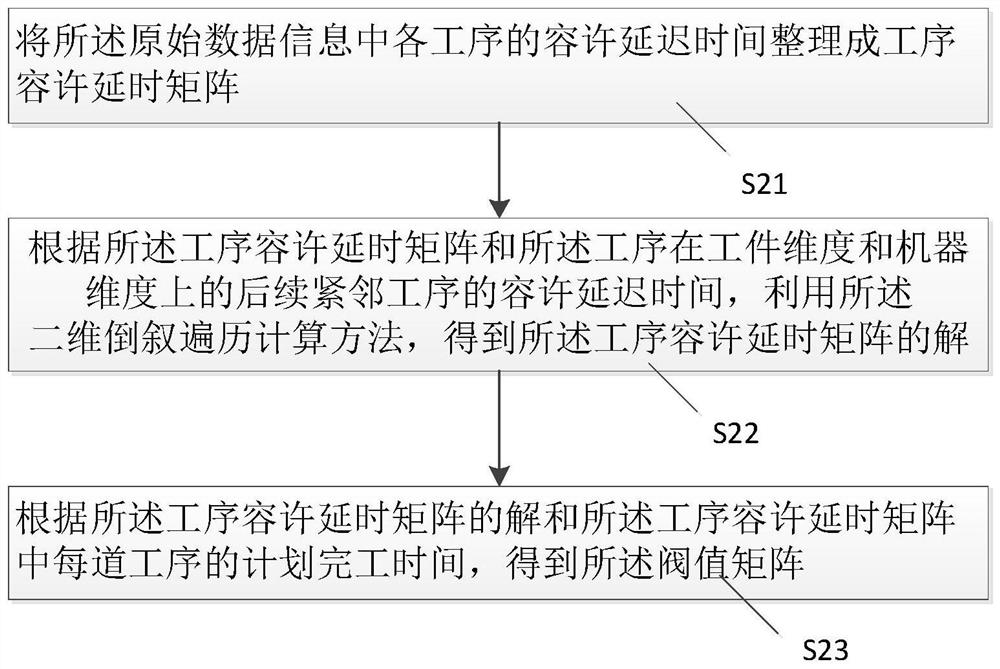

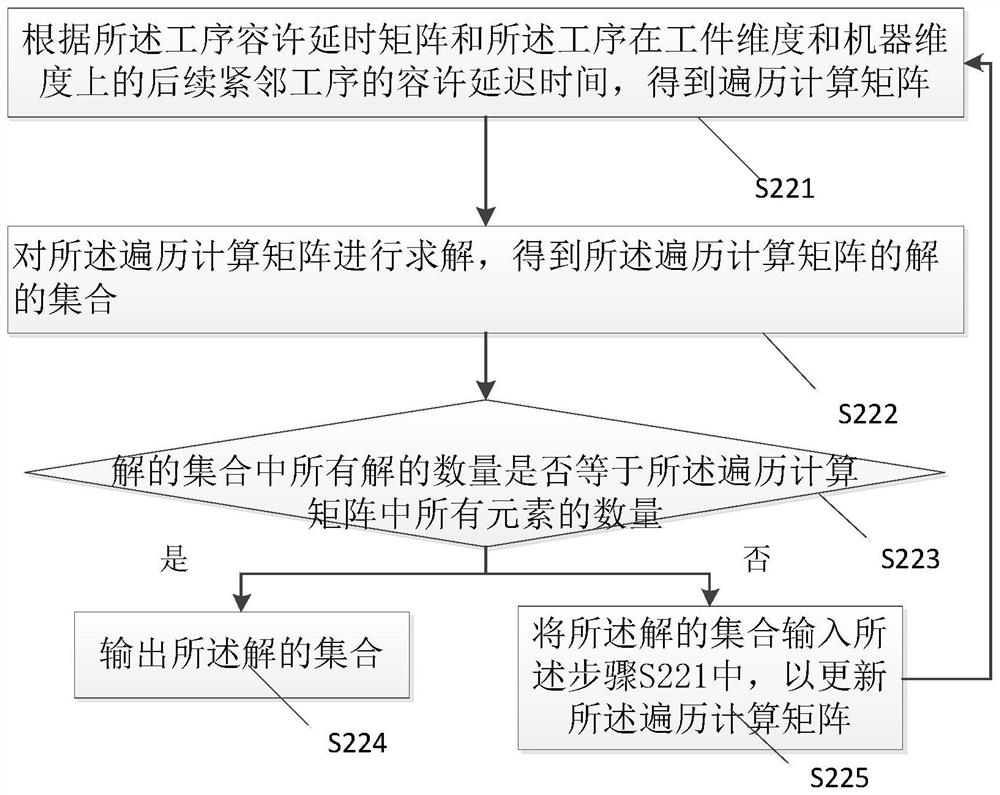

[0058]S2: According to the original data, using a two-dimensional reverse traversal calculation method to generate a threshold value matrix, wherein each element in the threshold value matrix represents the latest completion time of the corresponding process;

[0059] S3: Determine whether the actual process completion time is less than or equal to the latest completion time, if so, enter step S4; otherwise, enter step S5;

[0060] S4: Outputting the original scheduling scheme as the scheduling scheme of the flexible job shop;

[0061] S5: Obtain the latest completion time of the disturbed pr...

Embodiment 2

[0092] In flexible job shop production, the connections between many processes are complicated. When a certain process is delayed, many processes or even the entire system are often affected. Figure 4 It shows the dynamic relevance of the scheduling scheme, and describes the linkage impact brought by the delayed disturbance in the process 201.

[0093] When O 201 When a disturbance occurs, it will directly affect the two processes O 102 and O 302 , thus indirectly affecting the process O 203 , O 402 , O 303 , O 103 . It can be clearly seen that each process directly affects at most two processes, namely the immediately following process on the machine and the next immediately adjacent process on the workpiece. This paper summarizes these two effects into two dimensions, namely machine dimension and workpiece dimension.

[0094] There are many common disturbances in the flexible job shop, such as emergency insertion, machine failure, workpiece rework and scrap, tempora...

Embodiment 3

[0152] The generation program of the original scheduling plan in this paper uses Matlab software and genetic algorithm. The number of machines is 10, the number of workpieces is 6, the number of processes is 6, the number of populations is 40, the cycle iteration is 50 generations, the mutation rate is 0.6, and the crossover rate is 0.8. Table 2 and Table 3 show the list of optional processing machines for the process and the processing schedule of the process:

[0153] Table 2 Process optional processing machine list

[0154]

[0155] Table 3 Process Processing Timetable

[0156]

[0157] by Figure 6 Take the original scheduling plan in the example as an example, assuming that the delivery date of each workpiece is 44. when process O 21 Compared with the original scheduling plan, the completion time is delayed by 1, that is, the completion time is changed from 6 to 7. At this time, rescheduling is not triggered, and only the corresponding affected processes need to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com