Micromechanical sensor device with movable gate and corresponding production method

A technology of micromechanical sensors and gates, applied in the direction of microstructure devices composed of deformable elements, microstructure devices, manufacturing microstructure devices, etc., to achieve the effects of reducing leakage current, improving SNR, and reducing thermal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

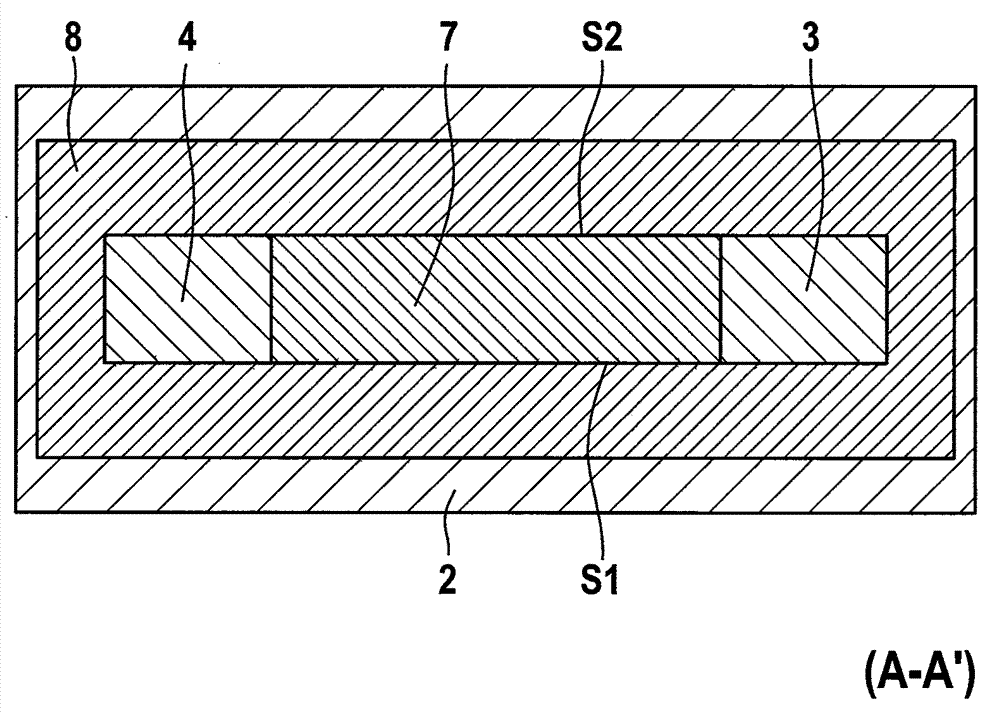

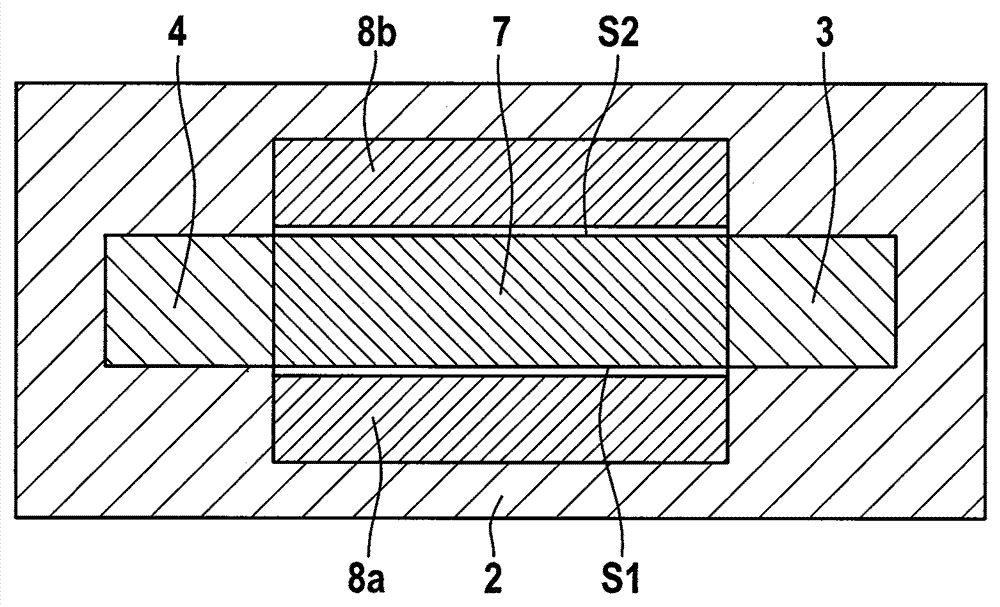

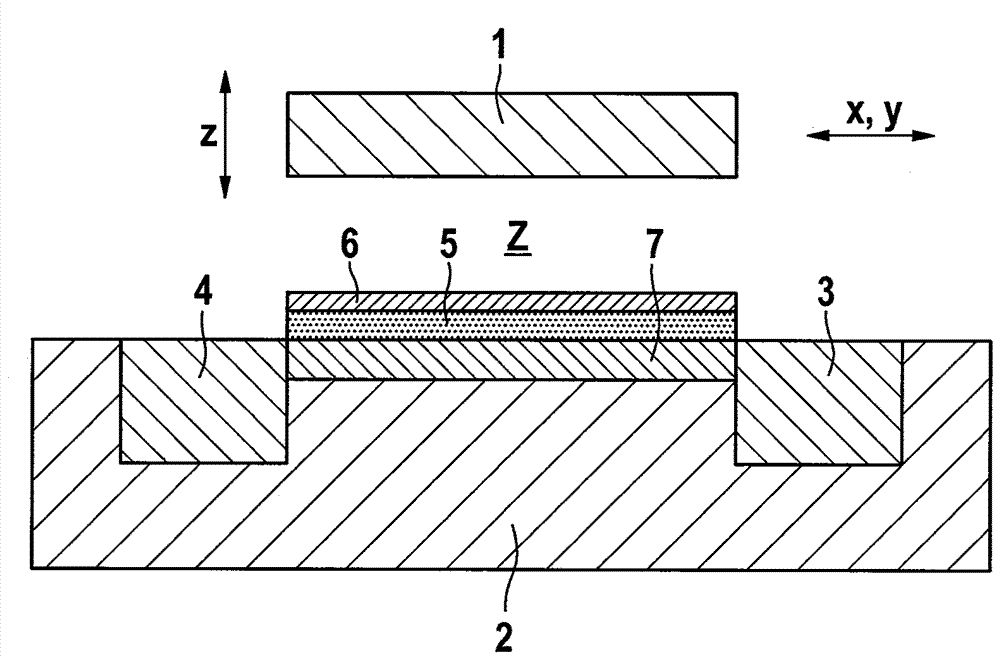

[0021] 1 a ) and 1 b ) are schematic cross-sectional views for illustrating a micromechanical sensor device with movable gates and a corresponding manufacturing method according to an embodiment of the invention, more precisely 1 a ) is a vertical cross-sectional view and FIG. 1 b ) is a horizontal cross-sectional view along line AA' in FIG. 1 a ).

[0022] In FIG. 1 a ) and FIG. 1 b ), the reference numeral 2 designates the silicon substrate in which the drain region 3 , the source region 4 and the channel region 7 in between of the field effect transistor are arranged. A gate insulating layer 5 , for example an oxide layer, is arranged on the channel region 7 . The surface charges on the insulating layer 5 are indicated with reference numeral 6 . The movable gate electrodes 1 are movably arranged on the base body 2 separated by a gap Z.

[0023] different from according to image 3 The above-mentioned known micromechanical sensor device, the embodiment of the invention has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com