Flower basket structure of solar cell slice

A technology of solar cells and sheets, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of increased solar cell preparation costs, complex overall structure of flower baskets, and reduced service life of flower baskets, etc., to achieve simple and efficient production and processing , simple structure, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

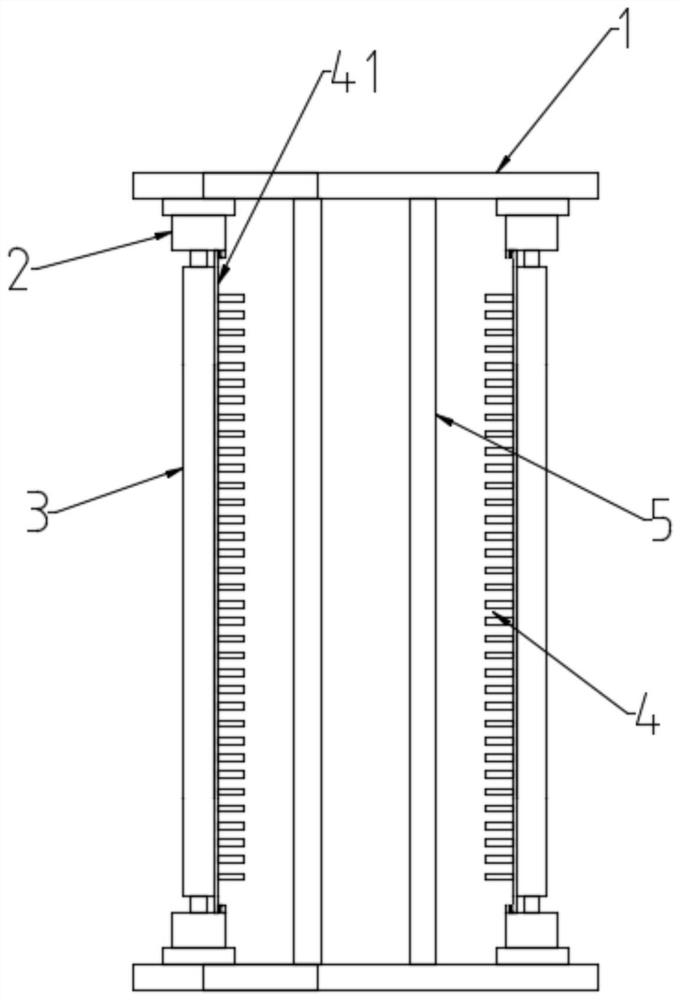

[0025] Combine below Figure 1-4 The present invention will be described in detail.

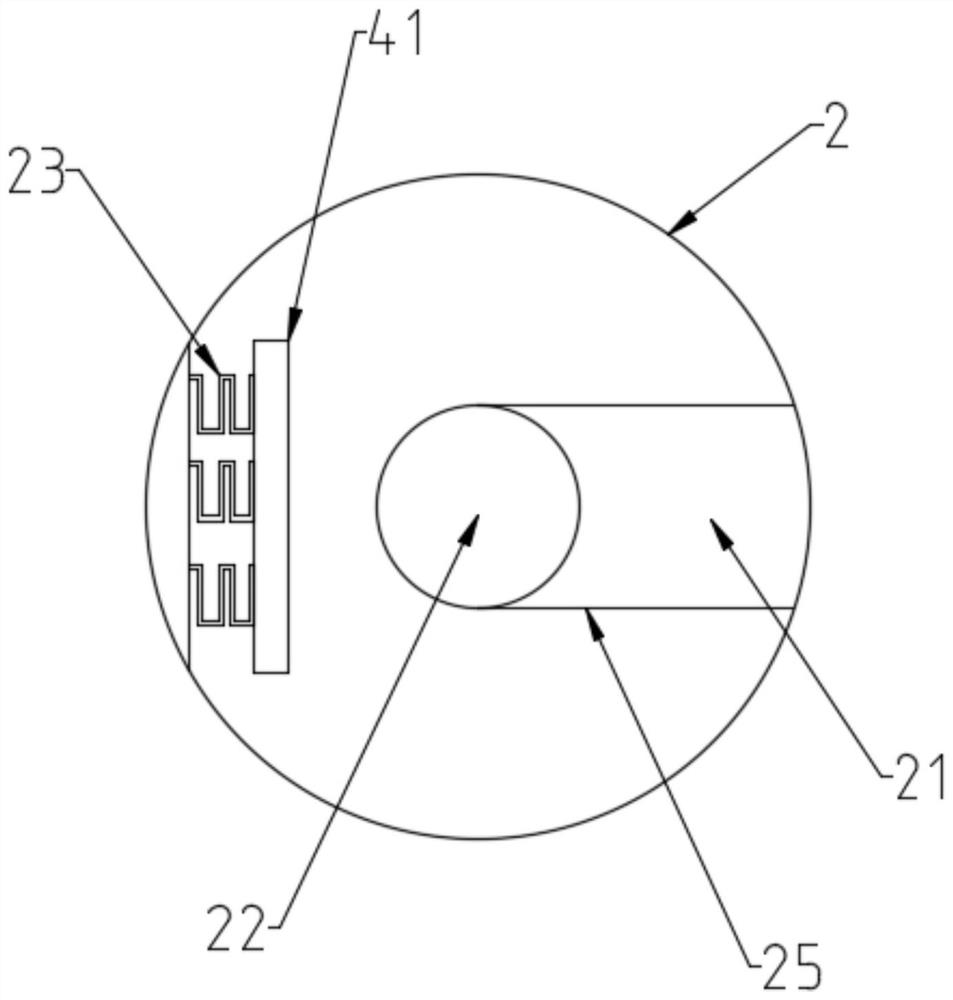

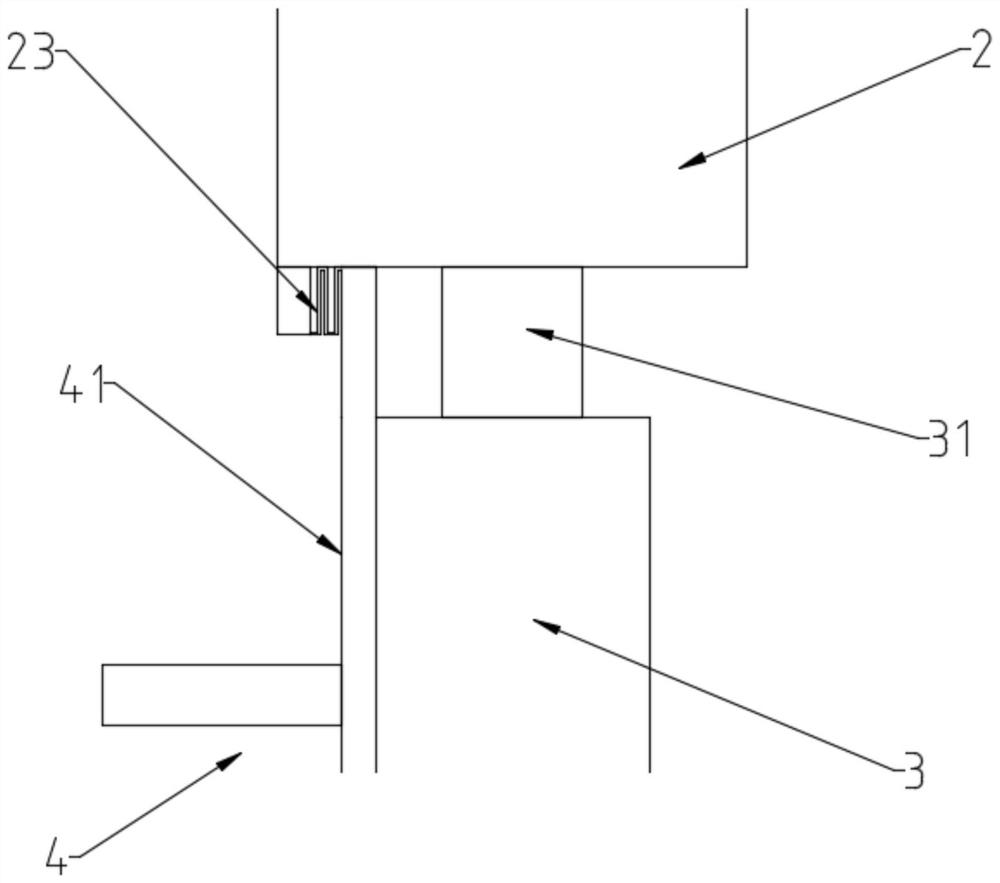

[0026] A flower basket structure of a solar cell sheet of the present invention, such as figure 1 , including the end plate 1 and the slot bar 41 arranged between the end plates 1, the slot bar 41 is provided with several slots 4, preferably 50 or 100 slots 4 are set, and the end plate 1 is provided with connecting part 2, the connecting part 2 is provided with four groups, two groups on the left side, two groups on the right side, and four groups of corresponding slot rods 41 and adjustment rods 3 are also provided, and the support rods 5 are located between the slot rods 41 on both sides. An insertion space is formed between the support rod 5 and the insertion rod 41, and the silicon wafer is inserted into the card slot 4 through the insertion machine.

[0027] The connecting part 2 is provided with a spring area 23, the spring area 23 and / or the connecting part 2 is made of PVDF (polyvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com