Elastic conduction temperature measurement assembly and socket

An elastic and component technology, applied in the field of elastic conduction temperature measuring components and sockets, can solve the problems of large error in test results, achieve the effect of good thermal conductivity, accurate test results, and automatic assembly

Pending Publication Date: 2022-03-01

CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide an elastic conduction temperature measurement component to solve the technical problem of large error in detection results in the prior art; also provide a socket using the elastic conduction temperature measurement component to solve the above technical problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0039] The socket includes a socket housing and terminals arranged in the socket housing. The socket also includes an elastic conduction temperature measuring component for measuring the temperature of the terminals. The structure of the elastic conduction temperature measuring component is consistent with the prior art and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

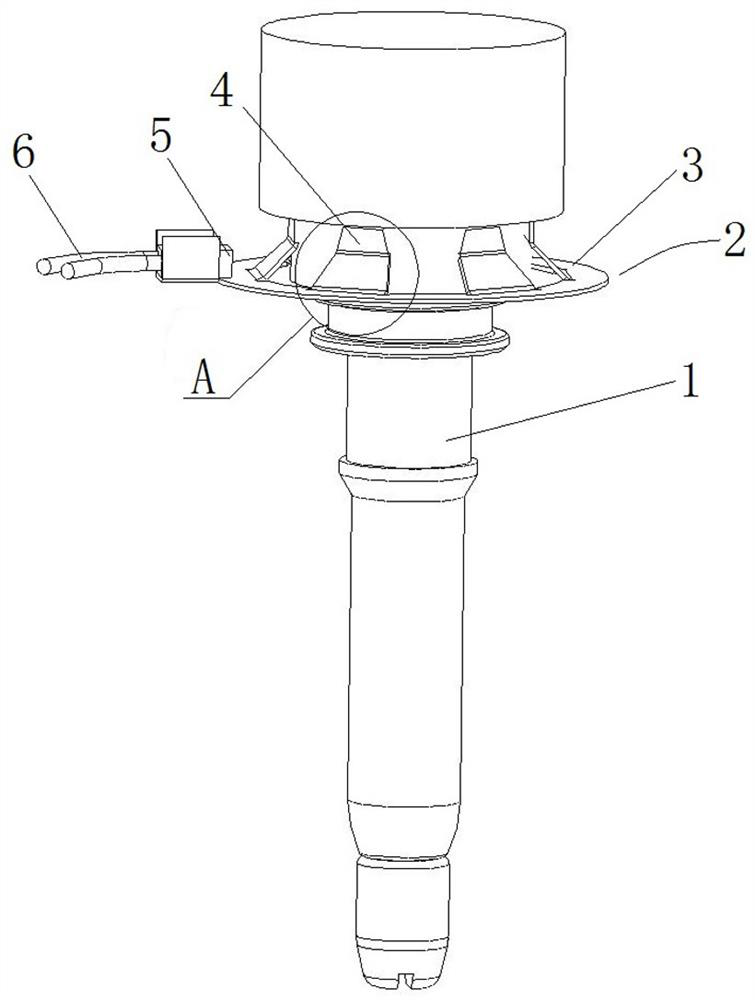

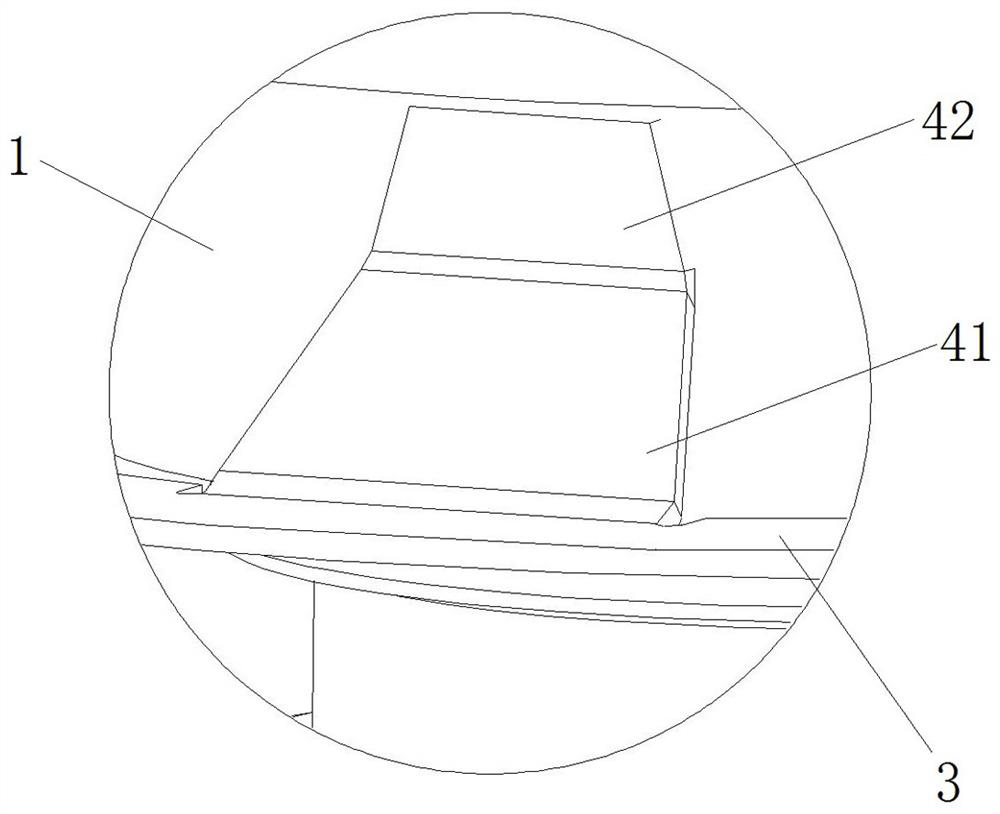

The invention belongs to the technical field of connectors, and particularly relates to an elastic conduction temperature measurement assembly and a socket, the elastic conduction temperature measurement assembly comprises a heat conduction metal contact piece, the heat conduction metal contact piece comprises a heat conduction metal ring which is sleeved outside a terminal when in use, and the heat conduction metal ring is provided with a temperature measurement chip; the heat conduction metal ring is provided with a metal elastic sheet, and the end part of the metal elastic sheet is used for elastic deformation so as to be in elastic contact with a terminal in the heat conduction metal ring. And at least two metal elastic sheets are arranged at intervals along the circumferential direction of the heat-conducting metal ring, and each metal elastic sheet is used for clamping the terminal in a matched manner. On one hand, the heat-conducting property of the metal elastic sheet is better, and the detection result is more accurate; and on the other hand, the metal elastic sheet is in elastic contact with the terminal, so that automatic assembly is facilitated, and the condition that heat-conducting glue is not easy to coat or covers a conductive part of the terminal in the prior art is not easy to occur.

Description

technical field [0001] The invention belongs to the technical field of connectors, and in particular relates to an elastic conduction temperature measuring component and a socket. Background technique [0002] According to the requirements of GB18487.1-2015, in applications where the rated charging current is greater than 16A, the power supply socket and vehicle socket should be equipped with temperature monitoring devices, and the power supply equipment and electric vehicles should have temperature detection and interference protection functions. At present, most of the methods for measuring the temperature of the terminals of sockets on the market use indirect detection. There is a distance between the temperature sensor and the terminal (the heating element to be tested) to ensure electrical isolation, which also leads to the difference between the actual temperature of the terminal and the temperature sensor. The measured temperature varies greatly, the detection respons...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01R13/40H01R13/02H01R13/66G01K1/14G01K7/00

CPCH01R13/40H01R13/02H01R13/66G01K1/14G01K7/00

Inventor 李晨光王伟

Owner CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com