Tunable integrated photo-production microwave source chip and system based on lithium niobate film

A photo-generated microwave, lithium niobate technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of complex structure and large volume, and achieve the effect of volume reduction, miniaturization, and engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

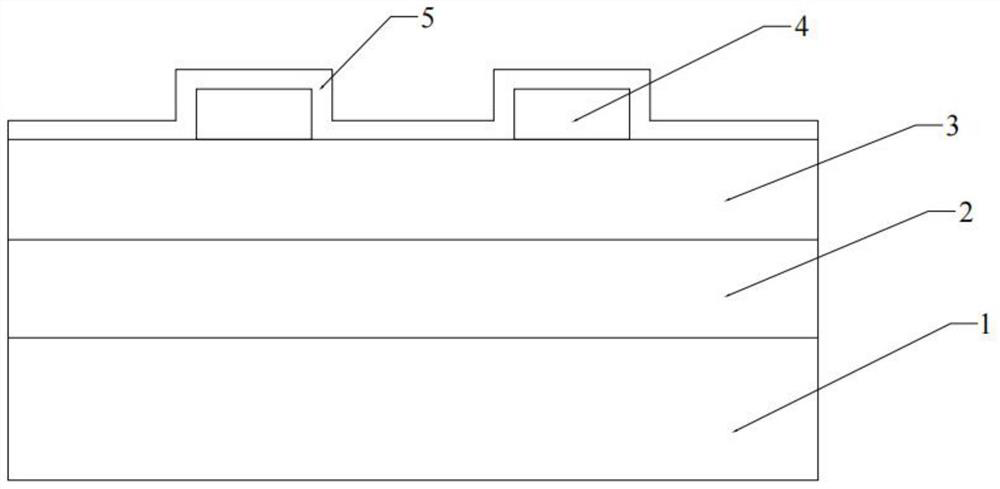

[0026] Please refer to Figure 1 to Figure 3 , this embodiment provides a tunable integrated photo-generated microwave source chip based on a lithium niobate thin film, including a base wafer 1, a lower cladding layer 2, a lithium niobate thin film 3, and an upper cladding layer 5 that are sequentially stacked from bottom to top; Wherein the base wafer 1 is a surface-polished silicon wafer, the upper cladding layer 5 and the lower cladding layer 2 are silicon dioxide layers respectively; the thickness of the lithium niobate thin film 3 is 300-1000 nm.

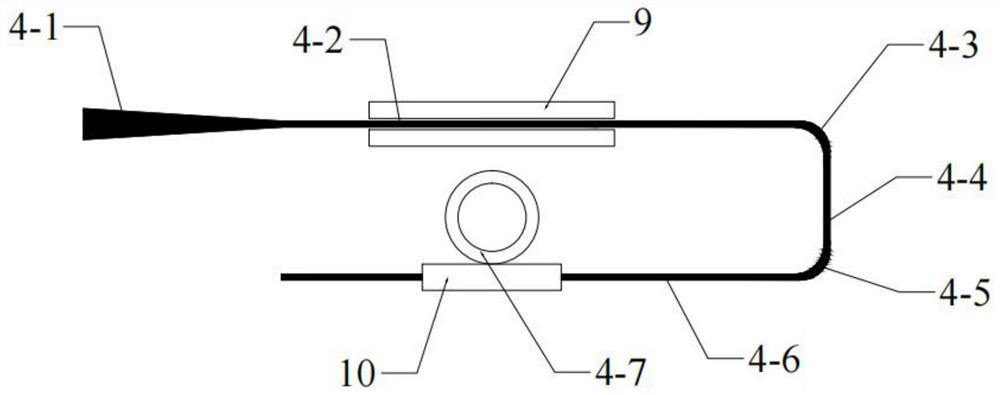

[0027] The lithium niobate thin film 3 is provided with a lithium niobate optical waveguide 4, that is, the lithium niobate optical waveguide 4 is fabricated in the lithium niobate thin film 3, and is fabricated by a dry etching process; image 3 As shown, the lithium niobate optical waveguide 4 includes a mode spot conversion waveguide 4-1, a first straight waveguide 4-2, a first curved waveguide 4-3, a second straight wavegui...

Embodiment 2

[0035] This embodiment provides a tunable integrated photo-generated microwave source chip based on lithium niobate thin film. structure, and in this embodiment, the optical microcavity waveguide 4-7 adopts a microdisk structure, such as Figure 4 shown.

Embodiment 3

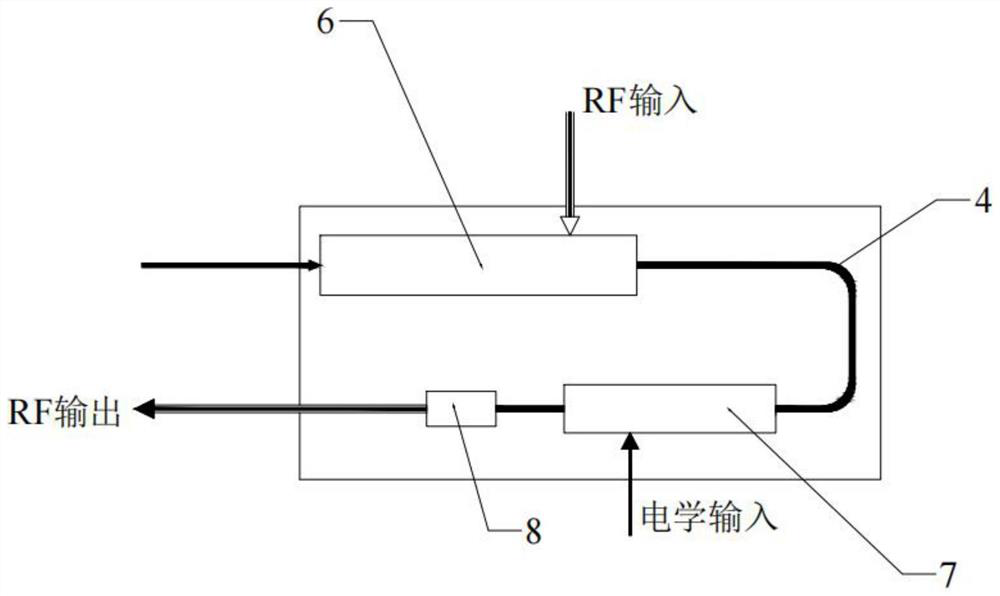

[0037] Please refer to Figure 5 , the present embodiment provides a tunable integrated photo-generated microwave source system based on lithium niobate thin film, the system includes the tunable integrated photo-generated microwave source chip based on lithium niobate thin film as described in embodiment 1, and also includes an electrical amplifier 11 , a radio frequency coupler 12 and a light source 13; wherein, the light source 11 is set close to the phase modulator 6, specifically close to the mode speckle conversion waveguide 4-1 of the phase modulator 6; the electrical amplifier 11 It is a GaAs low-noise radio frequency amplifier with a noise figure less than or equal to 2; the radio frequency coupler 12 is a GaAs radio frequency coupler with a coupling coefficient between 15 and 20 dB.

[0038] When the tunable integrated photo-generated microwave source system based on lithium niobate thin film provided in the embodiment of the present application is in use, the light em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coupling | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com