Driving assembly, camera module and electronic equipment

A technology for driving components and lenses, applied in televisions, electrical components, color televisions, etc., can solve the problems of different shapes of printed coils, increase production costs, and complicated current control, etc., to achieve simple wiring, save production costs, and reduce assembly Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the present invention, the X direction, the Y direction and the Z direction constitute a virtual coordinate system, the Z direction is the axis direction of the base 100, the X direction and the Y direction are perpendicular to each other and constitute a horizontal plane, and the horizontal plane is parallel to the base 100 The axial direction is vertical, wherein, the X direction is the transverse direction of the horizontal plane, and the Y direction is the longitudinal direction of the horizontal plane.

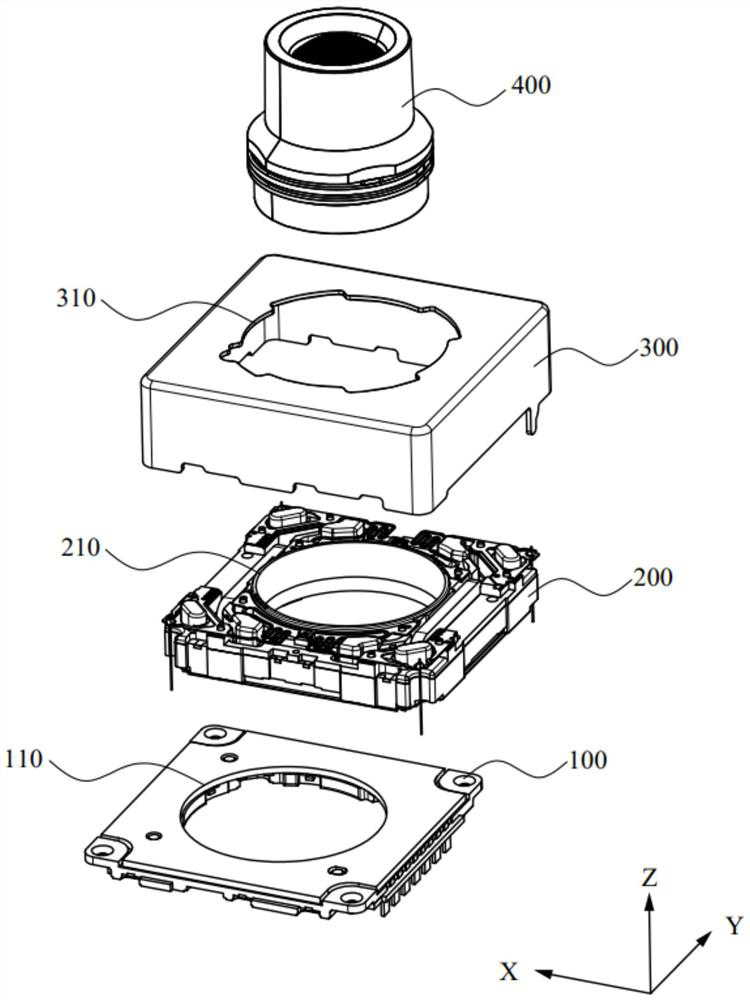

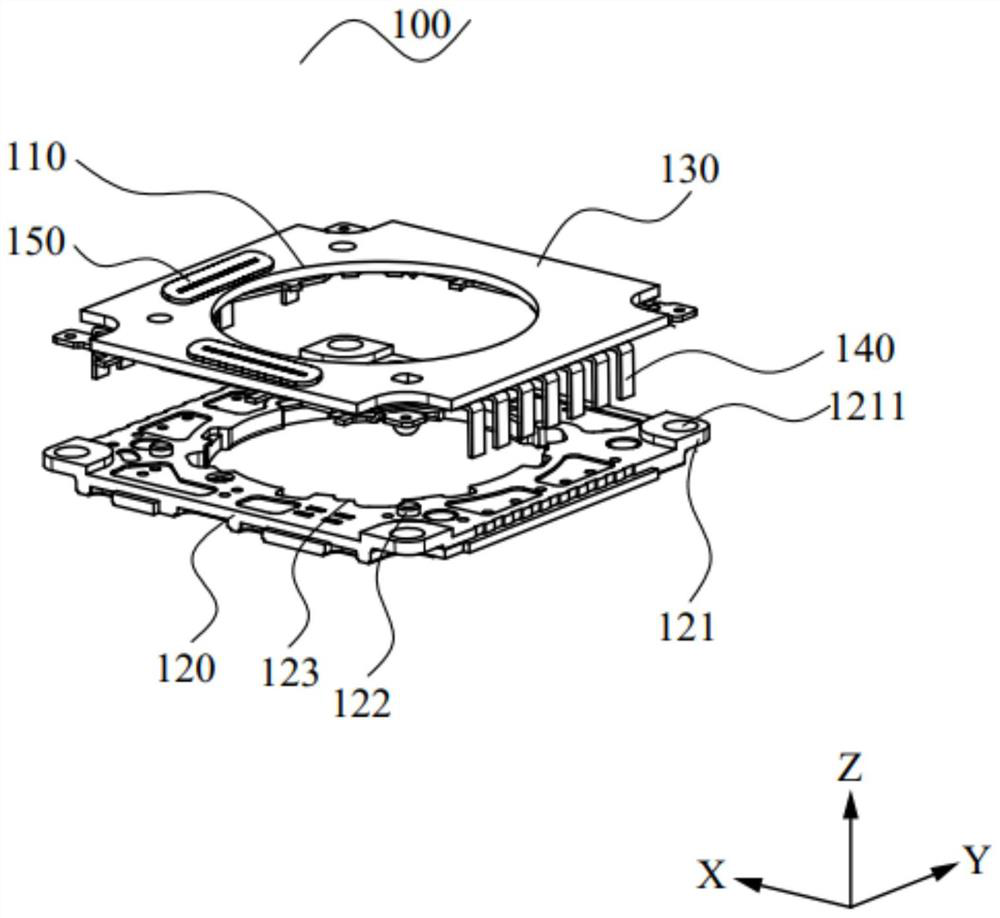

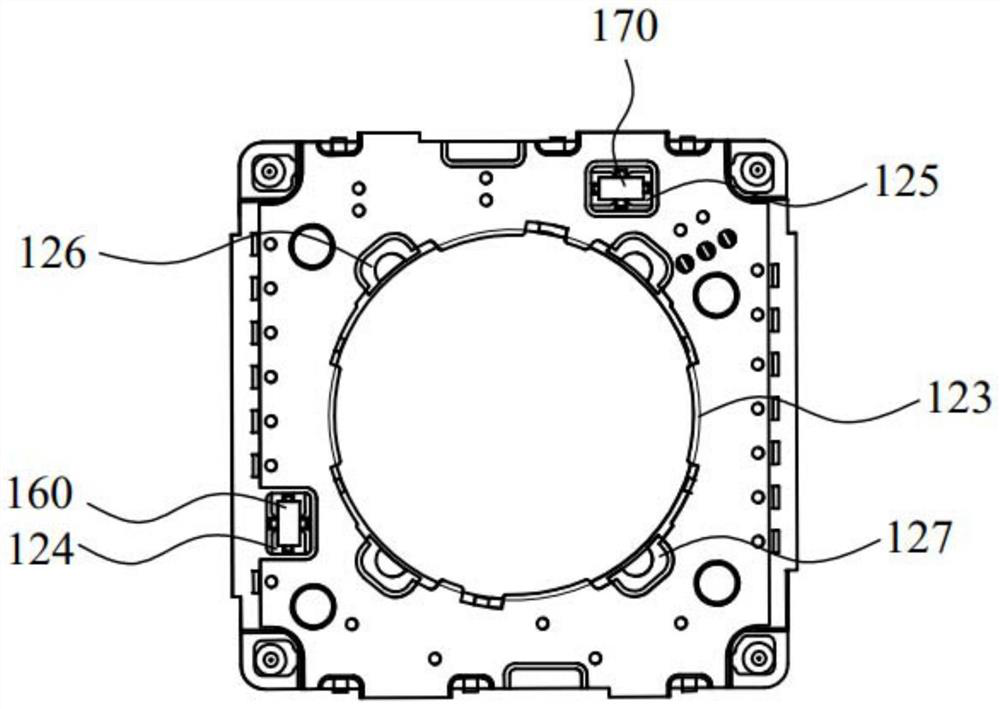

[0037] see Figure 1 to Figure 5 , shows the driving assembly in the first embodiment of the present invention. In the three-dimensional XYZ rectangular coordinate system, the driving assembly includes a base 100, a carrier 200 on the base 100, and a cover on the carrier 200 and The cover plate 300 on the base 100 is provided with an upper elastic piece 220 and a suspension wire 222 connecting the upper elastic piece 220 and the base 100 on the carrier 200. The ...

Embodiment 2

[0055] The present invention also proposes a camera module, the camera module includes a lens, an imaging sensor, and the above-mentioned drive assembly;

[0056] Wherein, the lens is arranged on the carrier and can move axially under the drive of the carrier, the imaging sensor is arranged on the side of the base away from the lens, and the imaging sensor and the The lenses are arranged relatively on the path of the optical axis.

Embodiment 3

[0058] The present invention also proposes an electronic device, including the above-mentioned camera module.

[0059] To sum up, the drive assembly, camera module and electronic equipment in the above-mentioned embodiments of the present invention divide the base into a circuit layer and a bottom plate, conduct electricity through the circuit layer, and drive the magnet to move along the X direction and / or Y direction, driving the magnet where it is located. The floating device moves along the X direction and / or Y direction, so that the Hall element senses the offset in the X direction and / or Y direction, so as to realize the position compensation of the shake and enhance the anti-shake performance. At the same time, by The connecting wires are embedded in the base, which can simplify the wiring of the connecting wires and reduce the assembly process and manufacturing process; specifically, the first groove and the second groove are arranged on the lower surface of the base, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com