Novel industrial switch dislocation cabinet device

A technology of industrial switches and switches, which is applied in the direction of selecting devices and electrical components, can solve the problems of poor heat dissipation performance of the device, stop operation of the device, poor waterproof performance, etc., and achieve improved heat dissipation performance, improved service life, good corrosion resistance and The effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

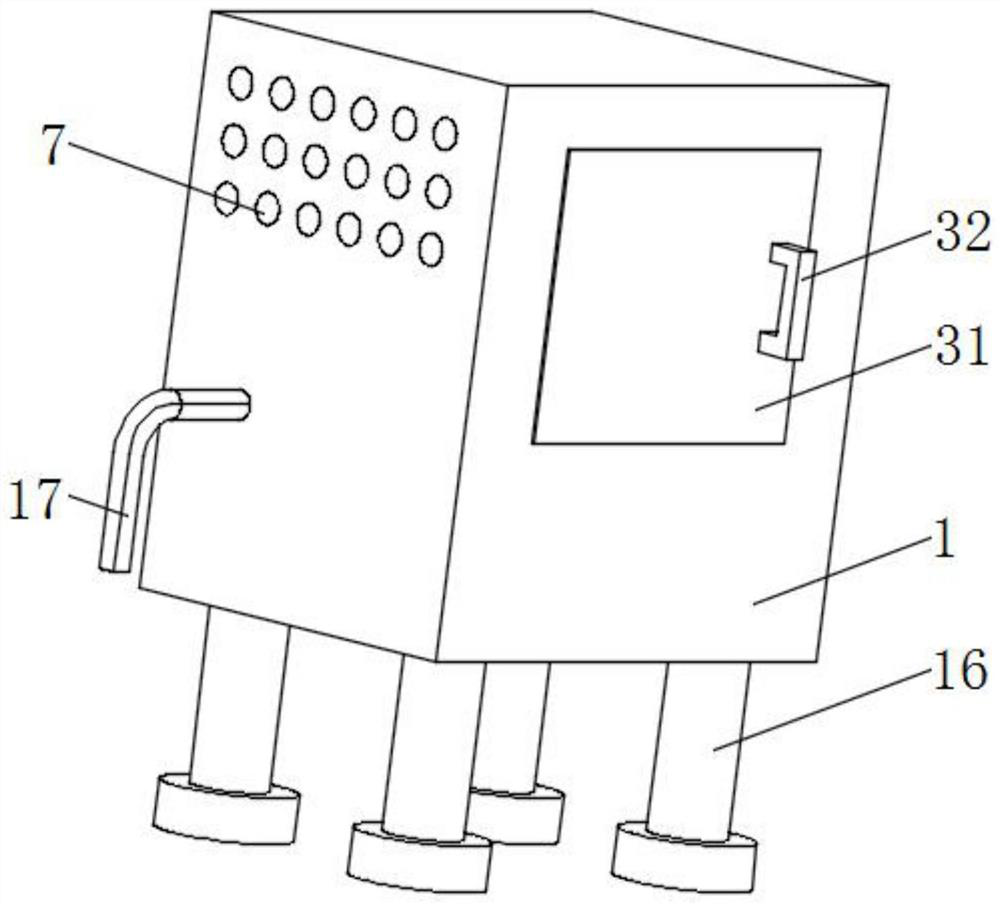

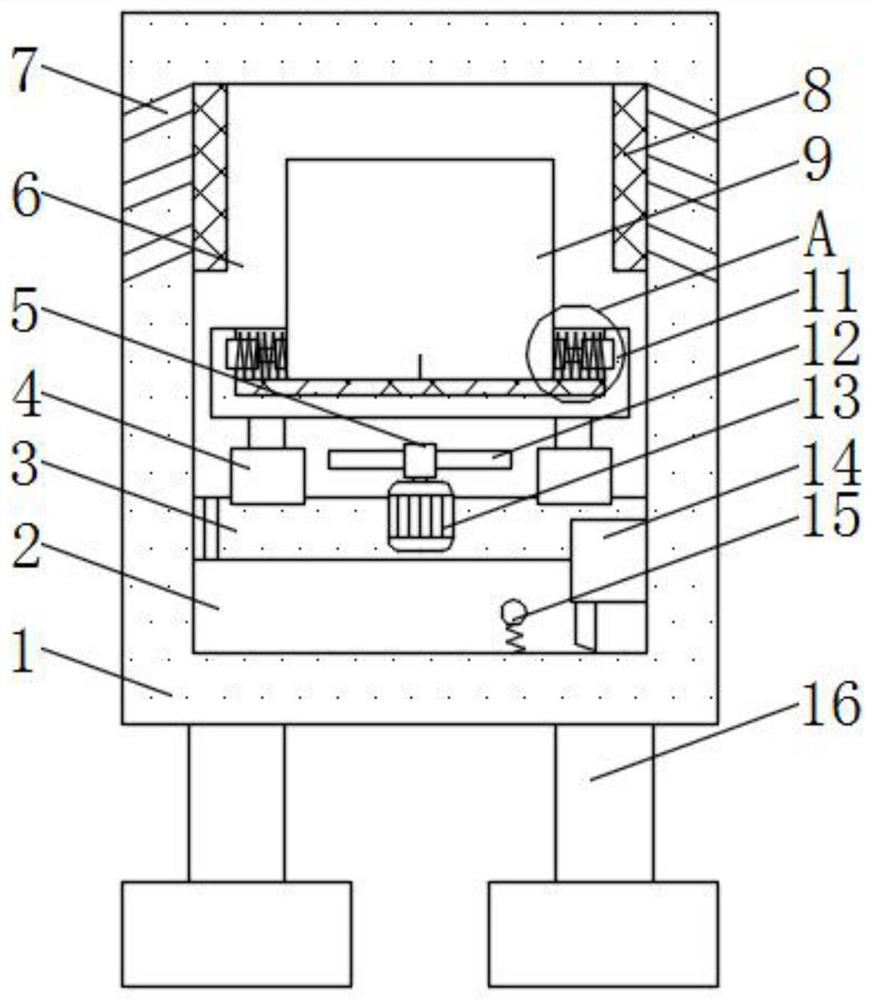

[0030] see figure 1 , figure 2 and Figure 4 , a new type of industrial switch cabinet device, including a box body 1, the inside of the box body 1 is fixedly connected with a support partition 3, the bottom of the support partition 3 is provided with a water storage tank 2, and the top of the support partition 3 is provided with an installation warehouse 6 , the inside of the installation warehouse 6 is provided with a support plate 11, the top of the support plate 11 is provided with a switch body 9, the box body 1 includes a corrosion-resistant layer 22, the bottom of the corrosion-resistant layer 22 is provided with a waterproof layer 23, and the bottom of the waterproof layer 23 is provided with There is a support layer 24, the bottom of the support layer 24 is provided with an insulating layer 25, the top of the front side of the cabinet 1 is provided with a cabinet door 31, and the middle part of the front side of the cabinet door 31 is fixedly connected with a handle...

Embodiment 2

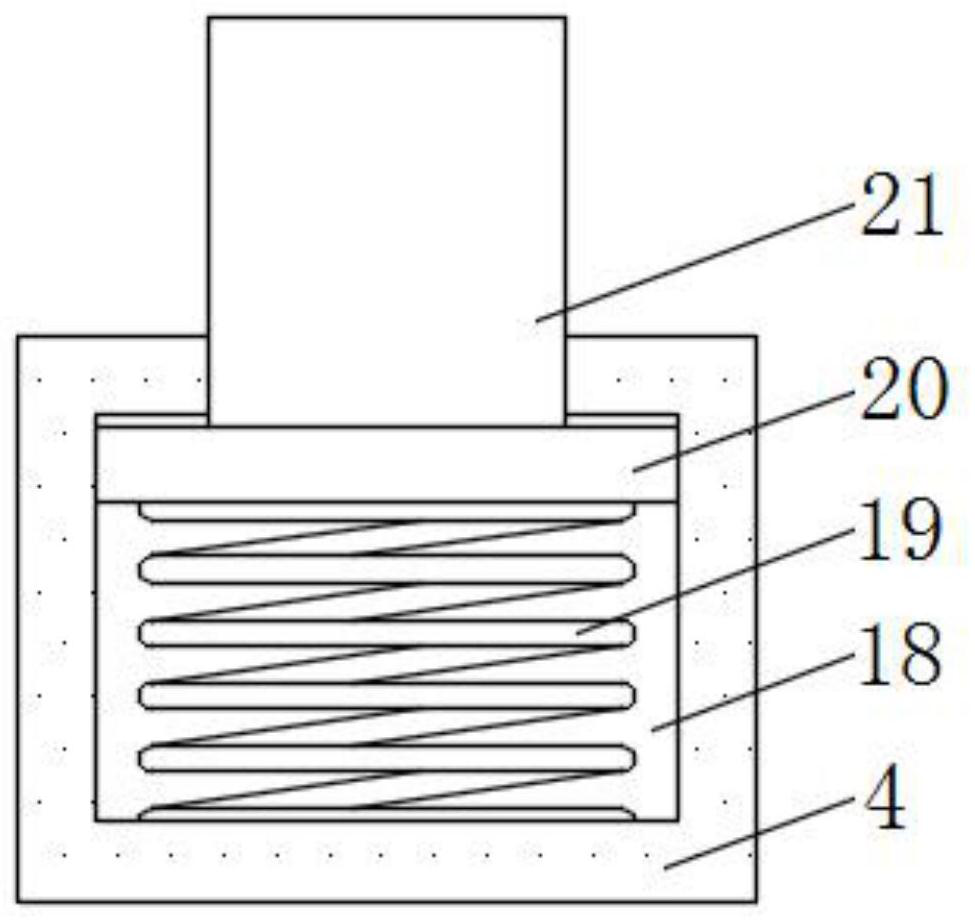

[0033] see figure 2 , image 3 and Figure 5 , this embodiment is further optimized on the basis of Embodiment 1, specifically, the bottom of the installation warehouse 6 is fixedly connected with the first shock absorbing device 4, there are four first shock absorbing devices 4, four first The damping devices 4 are evenly distributed in a rectangular shape, and there are two supporting plates 11 , which are symmetrically distributed.

[0034] Specifically, the inside of the first damping device 4 is provided with a damping chute 18, the top of the damping chute 18 is slidably connected with a damping slider 20, and the top middle of the damping slider 20 is fixedly connected with a support column 21, The top of the support column 21 protrudes from the damping chute 18 and is fixedly connected with the bottom of the support plate 11 , and the bottom of the damping slider 20 is fixedly connected with a first damping spring 19 .

[0035] Specifically, the top of the support ...

Embodiment 3

[0039] see figure 2 , the present embodiment is optimized as follows on the basis of example 1 or example 2, specifically, the middle part of the bottom end of the installation warehouse 6 is fixedly connected with a heat dissipation motor 13, and the output shaft of the heat dissipation motor 13 is fixedly connected with a connecting sleeve 5 , the outer wall of the connecting sleeve 5 is fixedly connected with cooling fan fins 12, there are four cooling fan fins 12, and the four cooling fan fins 12 are evenly distributed in a ring shape.

[0040] Specifically, the top of both sides of the inner wall of the installation warehouse 6 is provided with heat dissipation holes 7, and there are multiple heat dissipation holes 7, and the plurality of heat dissipation holes 7 are evenly and symmetrically distributed in the top of the inner wall of the installation warehouse 6 in a ring shape. The tops on both sides of the inner wall are fixedly connected with filter screens 8 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com