Manufacturing method for natural gas cylinder and natural gas cylinder

A manufacturing method and technology of natural gas, applied in the manufacture of container structures, details of ship construction, outer walls of container structures, etc., can solve the problems of low working pressure, high risk factor, short service time, etc., and achieve pressure bearing and deformation resistance The effect of strong ability, strong safety and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

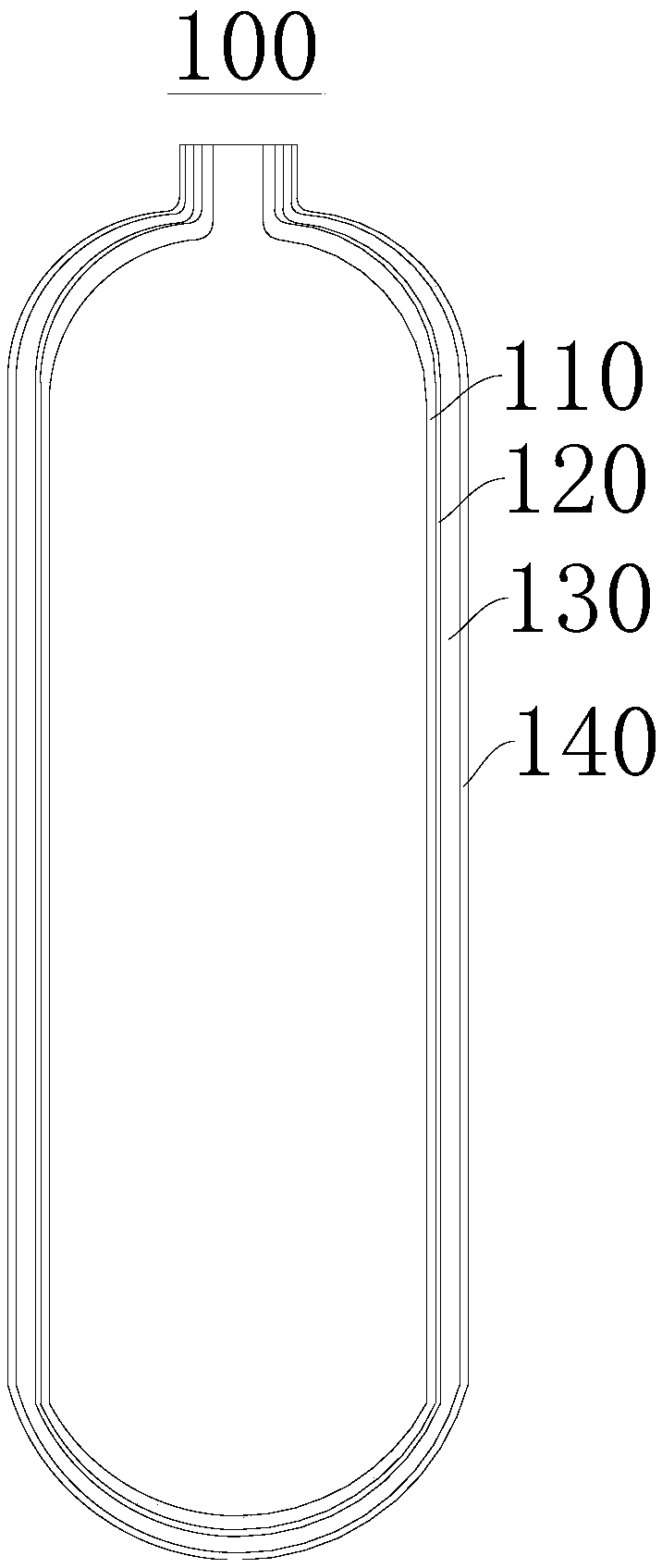

[0034] Please refer to figure 1 , the embodiment of the present invention provides a natural gas cylinder 100 for storing compressed natural gas as an important energy storage device for gas vehicles to provide power for gas vehicles. It has light weight, good insulation and corrosion resistance, no stress defect distribution, strong pressure bearing and deformation resistance, low manufacturing cost, strong safety, energy saving and environmental protection, and long service life.

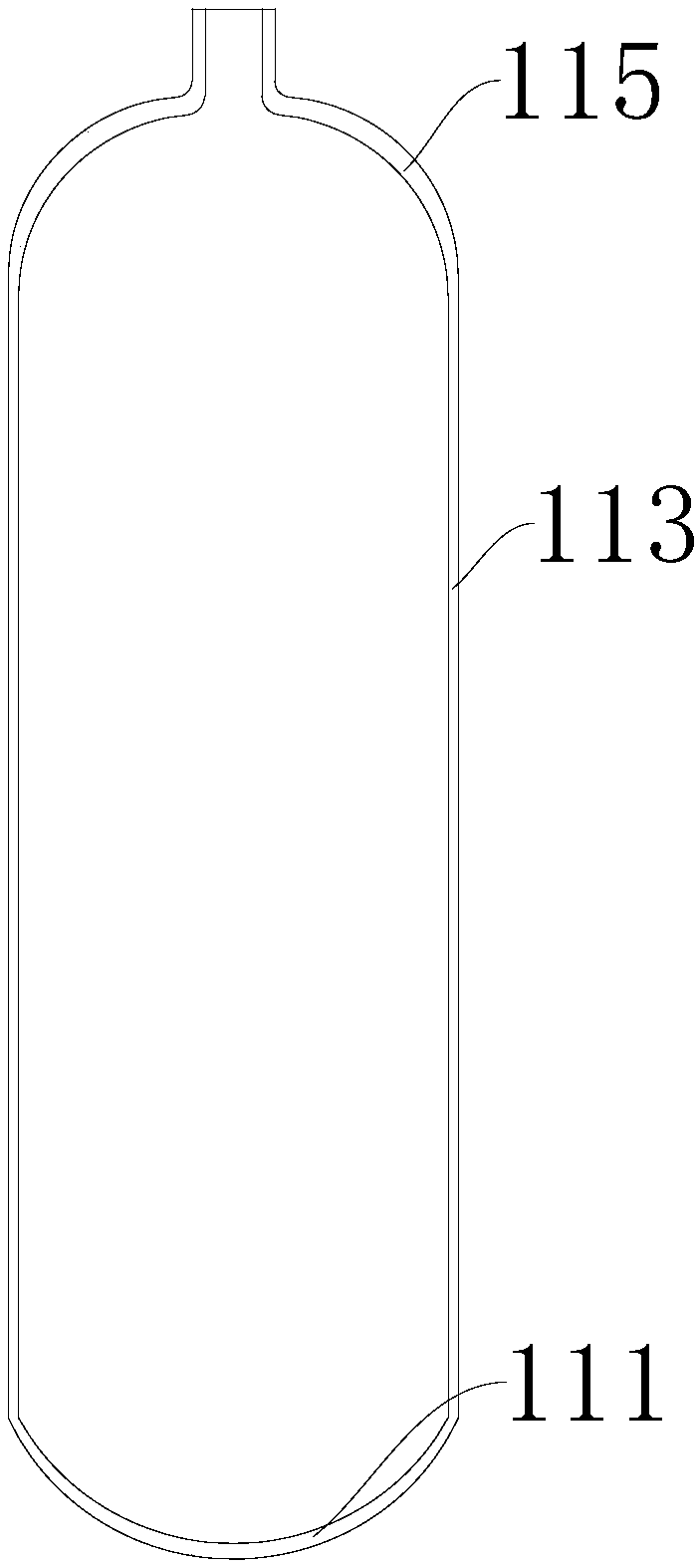

[0035] The natural gas cylinder 100 includes an inner lining layer 110 , an adhesive coordination layer 120 , a composite layer of bamboo strips 130 and an outer protective layer 140 . Wherein, the bonding coordination layer 120 is coated on the outside of the inner lining layer 110, and the bamboo strip composite layer 130 is wound and arranged outside the bonding coordination layer 120, and the bonding coordination layer 120 is used to bond and fix the bamboo strip composite layer 130, Prevent ...

no. 2 example

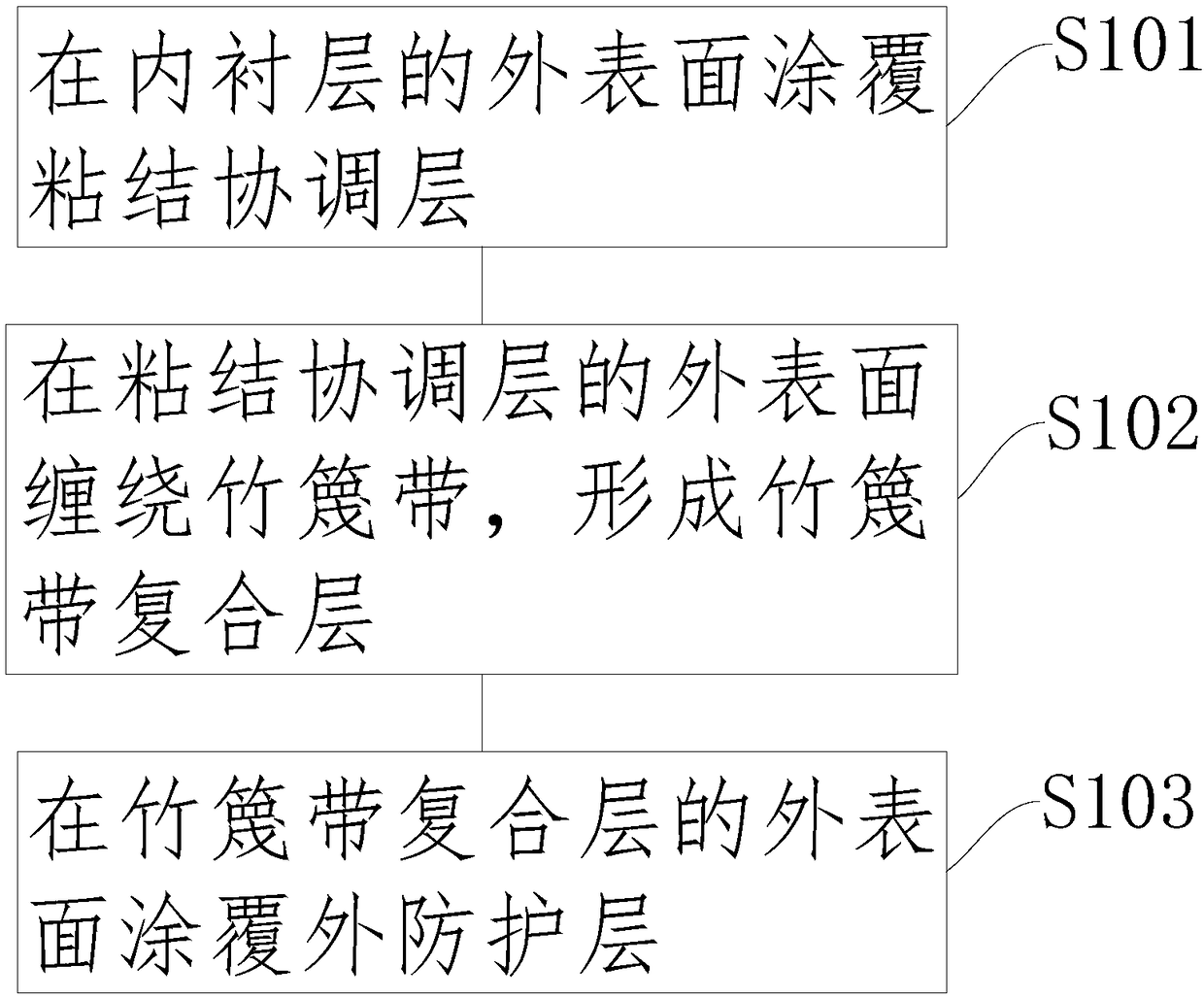

[0041] Please refer to image 3 , the embodiment of the present invention provides a method for manufacturing a natural gas cylinder, which is used for manufacturing the natural gas cylinder 100 . It is easy to operate, and can manufacture the natural gas cylinder 100 with light weight, good insulation and corrosion resistance, no stress defect distribution, strong pressure bearing and deformation resistance, low manufacturing cost, strong safety, energy saving and environmental protection, and long service life. The natural gas cylinder 100 can store compressed natural gas, and can be used as an important energy storage device for a gas vehicle to provide power for the gas vehicle.

[0042] The manufacturing method of the natural gas cylinder includes the following steps:

[0043] Step S101 : coating an adhesive coordination layer 120 on the outer surface of the inner lining layer 110 .

[0044] Specifically, the adhesion coordination layer 120 is made of epoxy resin and ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com