Tetrapeptide production purification device with impurity separation structure

A technology for separating structures and impurities, applied in separation methods, filtration separation, semi-permeable membrane separation, etc., can solve problems such as inconvenient for users to use, cumbersome purification device structure, poor impurity removal effect, etc., to achieve structural Simple, easy to collect, easy to adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

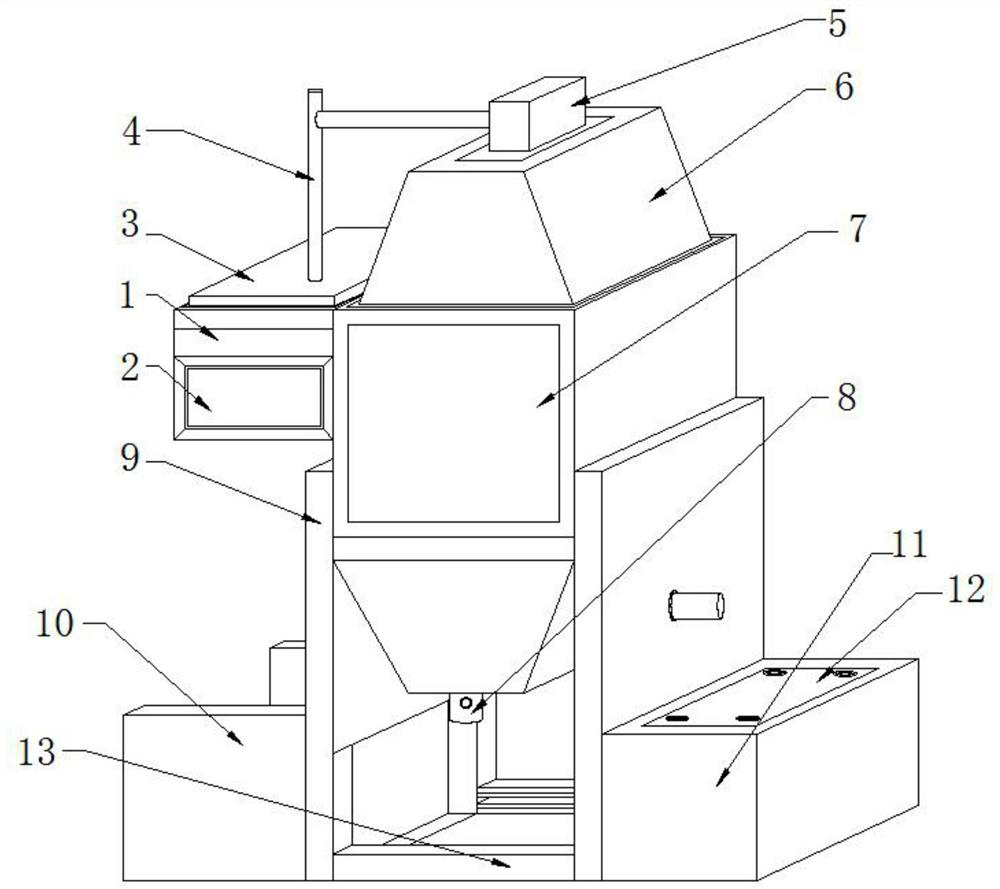

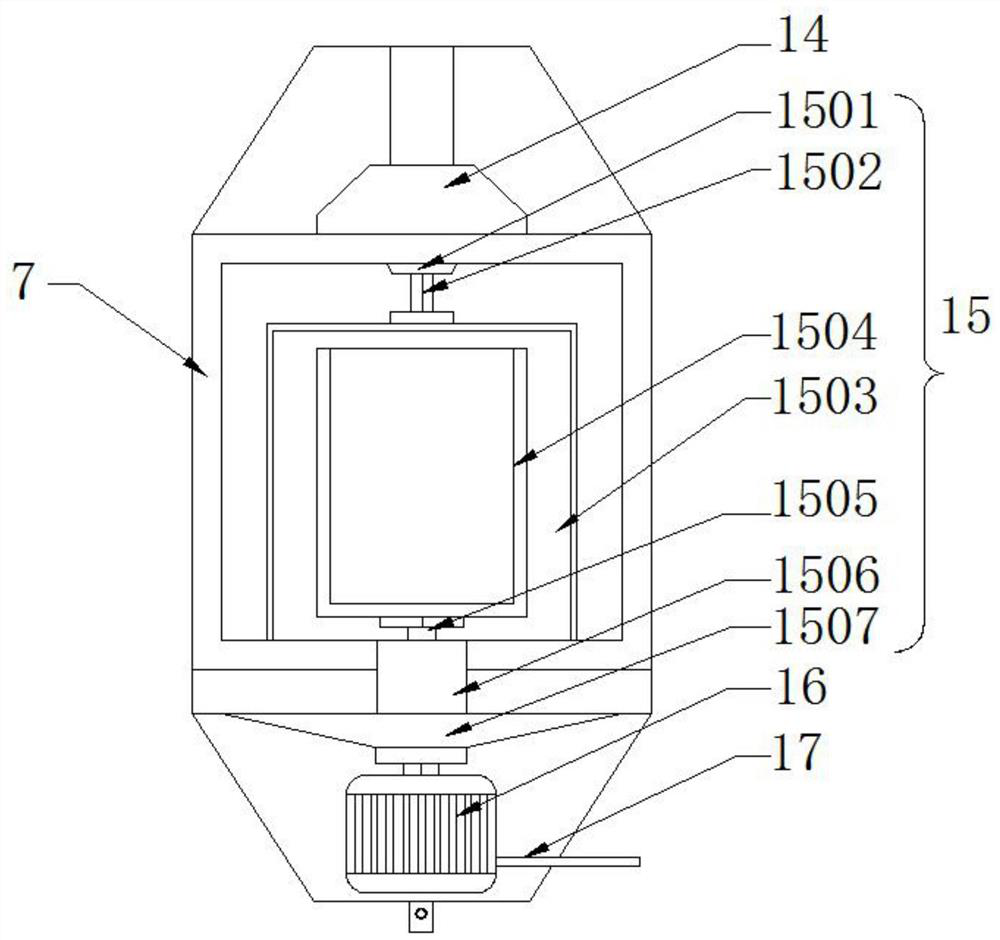

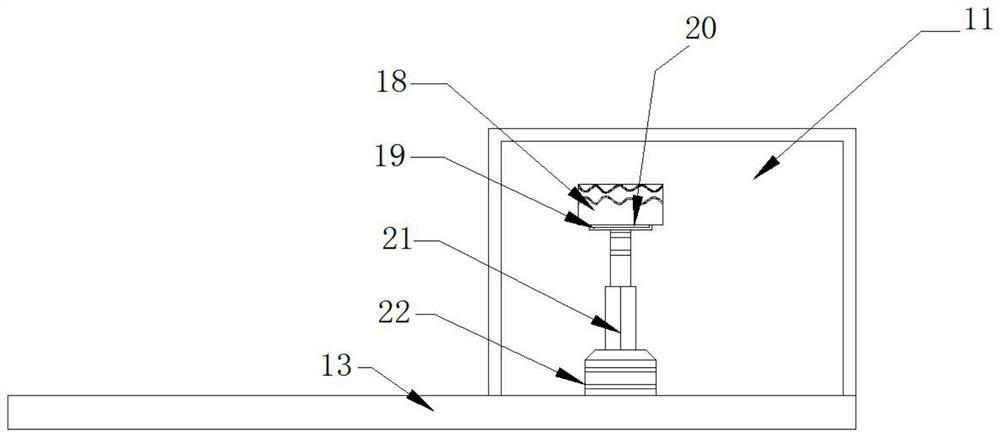

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a purification device for tetrapeptide production with an impurity separation structure, including a placement frame 1, a window 2, a top cover plate 3, a connecting pipe 4, a feeding port 5, a connecting frame 6, and a processing frame 7 , feeding pipe 8, support plate 9, side frame 10, side frame 11, fixed plate 12, electric slide rail 13, guide pipe 14, auxiliary assembly 15, first motor 1501, first rotating shaft 1502, first filter Frame 1503, second filter frame 1504, second rotating shaft 1505, second motor 1506, collector plate 1507, ultrafiltration membrane 16, side tube 17, cleaning cotton 18, horizontal plate 19, disinfection lamp 20, hydraulic air rod 21 , slider 22, baffle plate 23, collection assembly 24, connecting shaft 2401, servo motor 2402, connecting rod 2403, annular tube 2404, placing groove 2405, external groove 2406, slide rail 2407, water pump 25, storage chamber 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com