LED crystal grain appearance detection method

A technology of appearance inspection and grain, applied in sorting and other directions, can solve the problems of abnormal grains not being picked, easy to miss and pick by mistake, and abnormal quality, saving manpower and microscope costs, and realizing multiple reviews. and, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] A method for detecting the appearance of LED crystal grains provided by the application comprises the following steps:

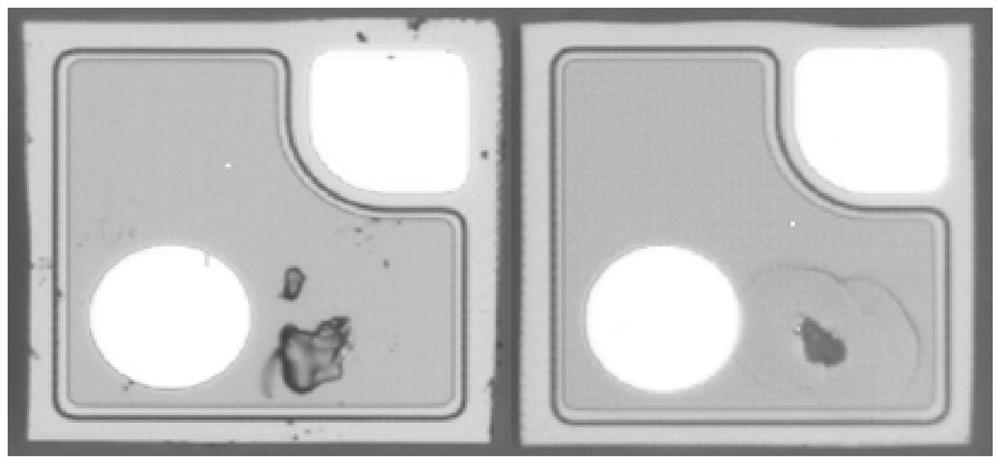

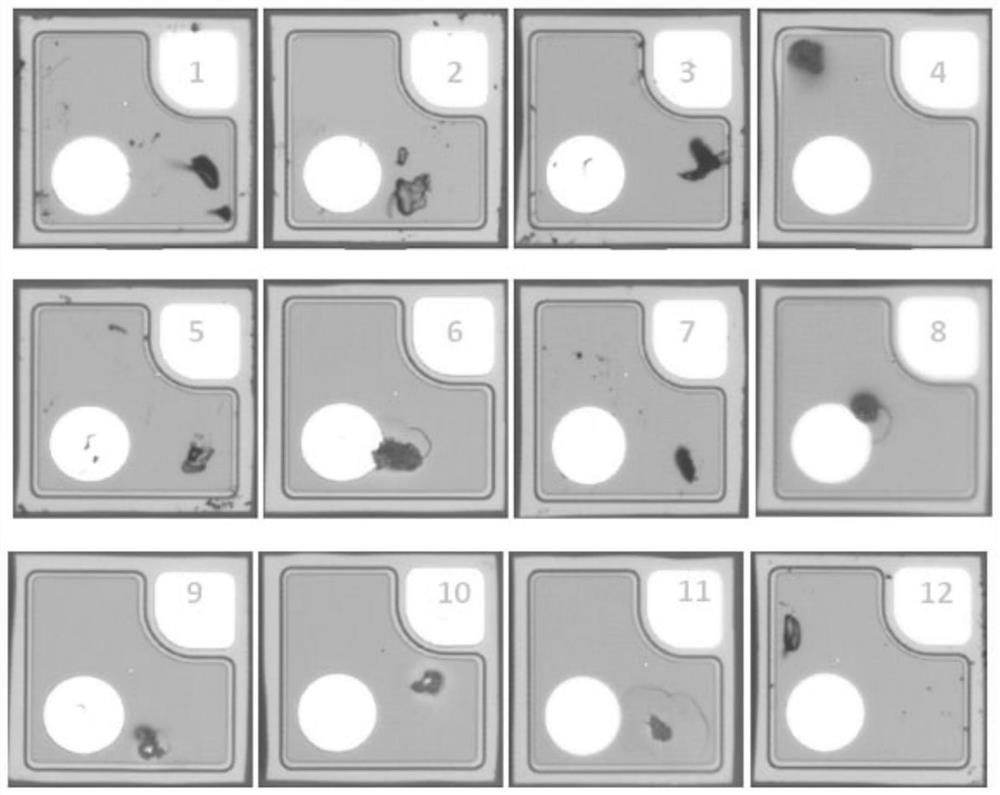

[0039] S1, carry out optical inspection to LED grain, obtain appearance parameter document, described appearance parameter document comprises grain defect area ratio;

[0040] Optical inspection is an appearance inspection method of LED grains to judge whether the appearance of LED grains meets the requirements, and the detection standards are set according to the application fields of LED grains and customer requirements.

[0041] Preferably, in the present application, the LED crystal grains are placed in an appearance automatic optical inspection device for optical inspection.

[0042] The appearance parameter document also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com