Method for automatically detecting voltage and internal resistance of battery and spraying code

An automatic detection and battery voltage technology, which is applied in the measurement of resistance/reactance/impedance, secondary battery manufacturing, and measurement of electricity, etc., can solve the problems that cannot be selected out, and bad products flow to customers, so as to avoid missed testing and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

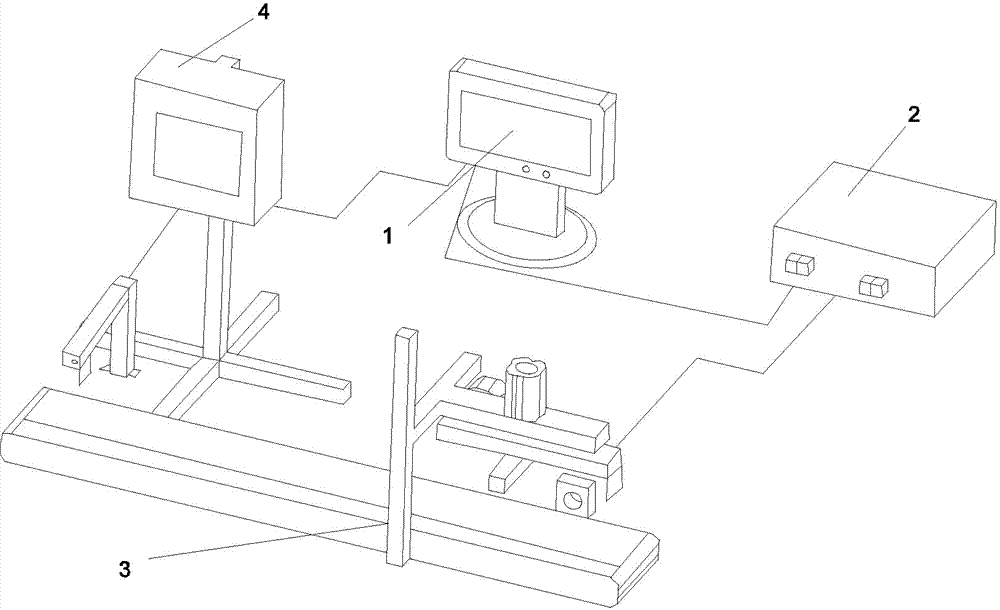

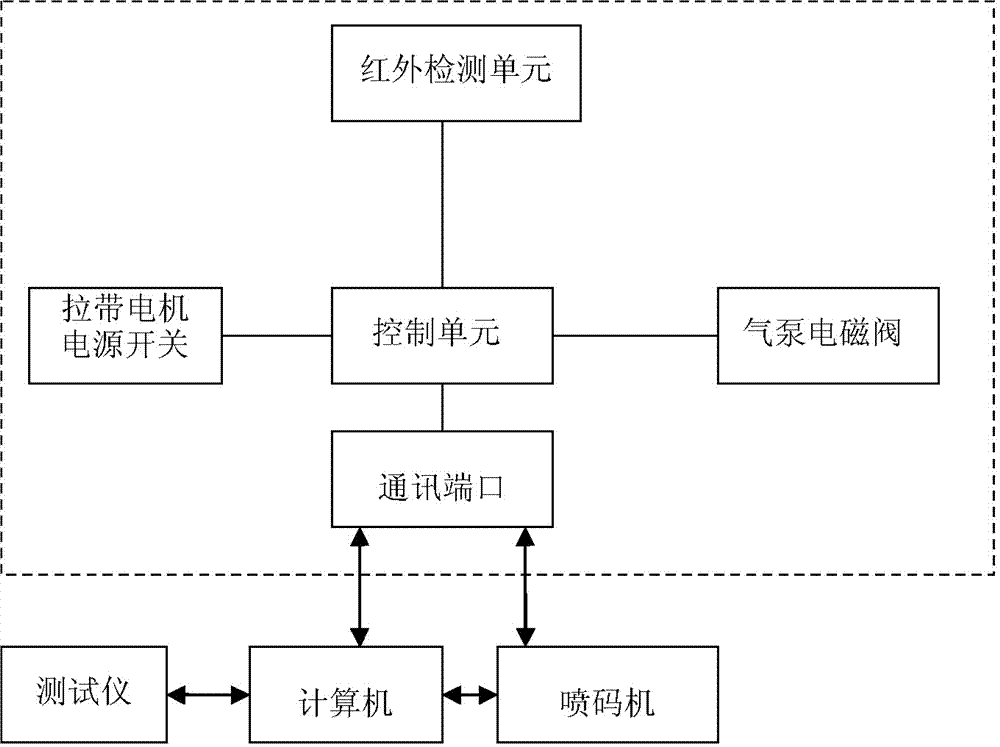

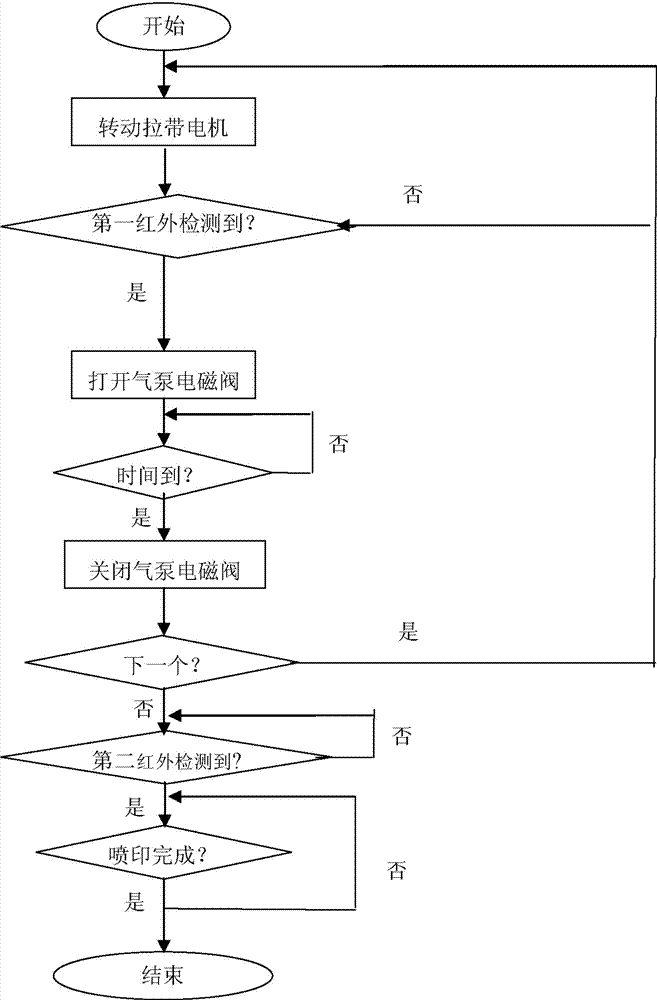

[0024] Such as figure 1 As shown, in the specific embodiment of the present invention, the integrated system of battery voltage and internal resistance detection and inkjet coding consists of an automatic detection and printing device 3 (including a drawstring mechanism, a test clamping mechanism located at the starting end of the drawstring mechanism, and the Test the infrared sensor of the clamping mechanism, the nozzle part of the inkjet printer 4 located at the tail end of the drawstring mechanism), the inkjet printer 4, the voltage internal resistance tester 2 connected to the test clamping mechanism via a line, and the voltage internal resistance tester 2 respectively. The resistance tester 2 and the inkjet printer 4 are composed of a computer 1 connected by lines, wherein: the control circuit and program set in the inkjet printing device 3 are automatically detected.

[0025] The pull belt mechanism is composed of a pull belt set on the driving wheels at both ends, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com