Method, system and device for determining maximum movement speed of filling wedge

A technology of moving speed and determination method, which is applied in the field of automobile stamping dies, can solve problems such as the reduction of stroke times and the reduction of cylinder movement speed, and achieve the effects of increasing movement speed, optimizing movement speed, and improving stamping production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

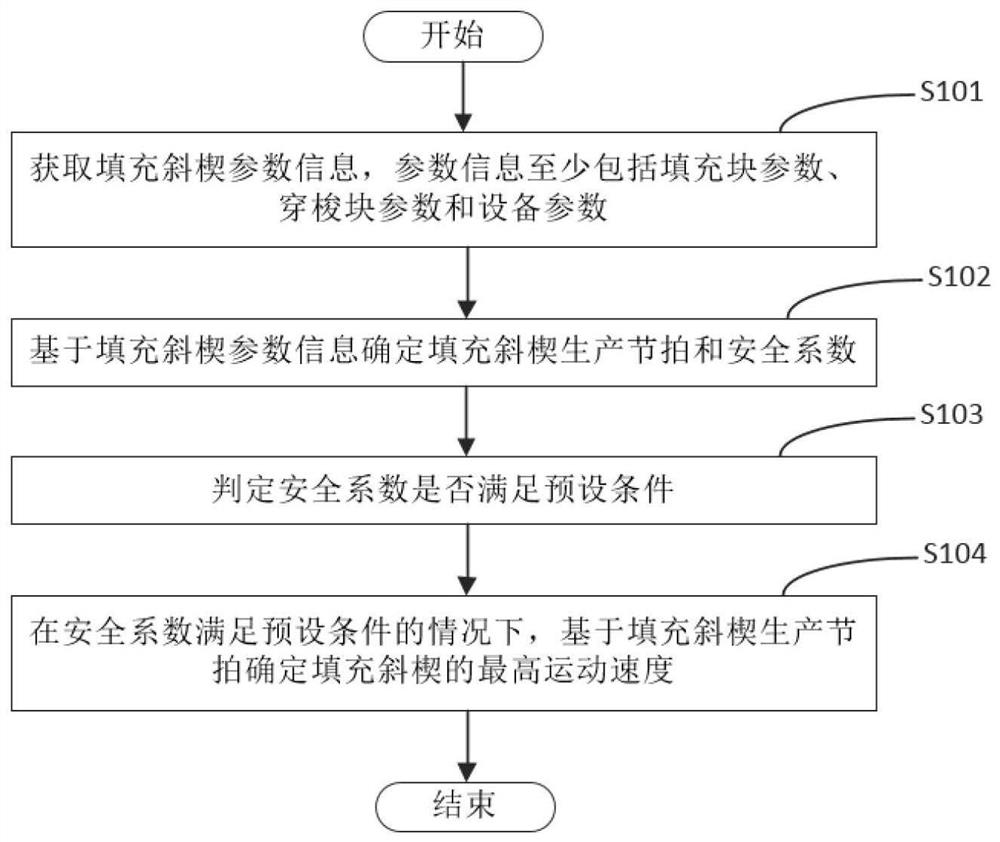

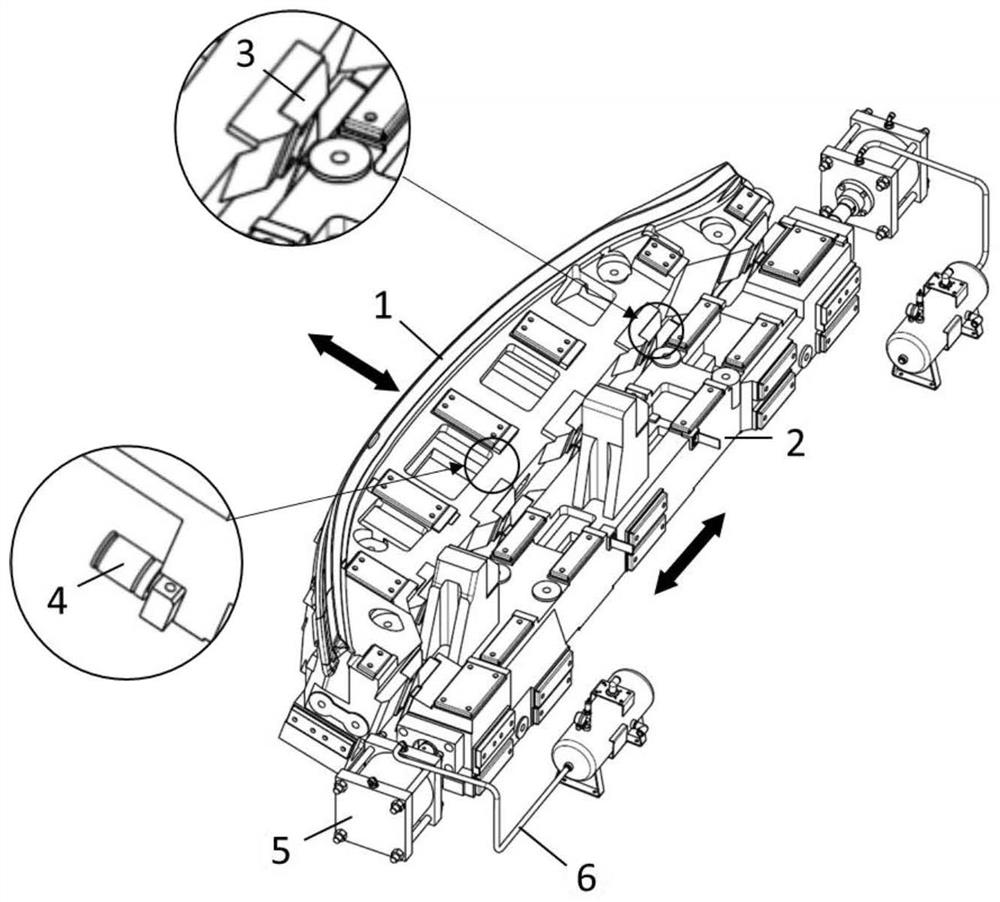

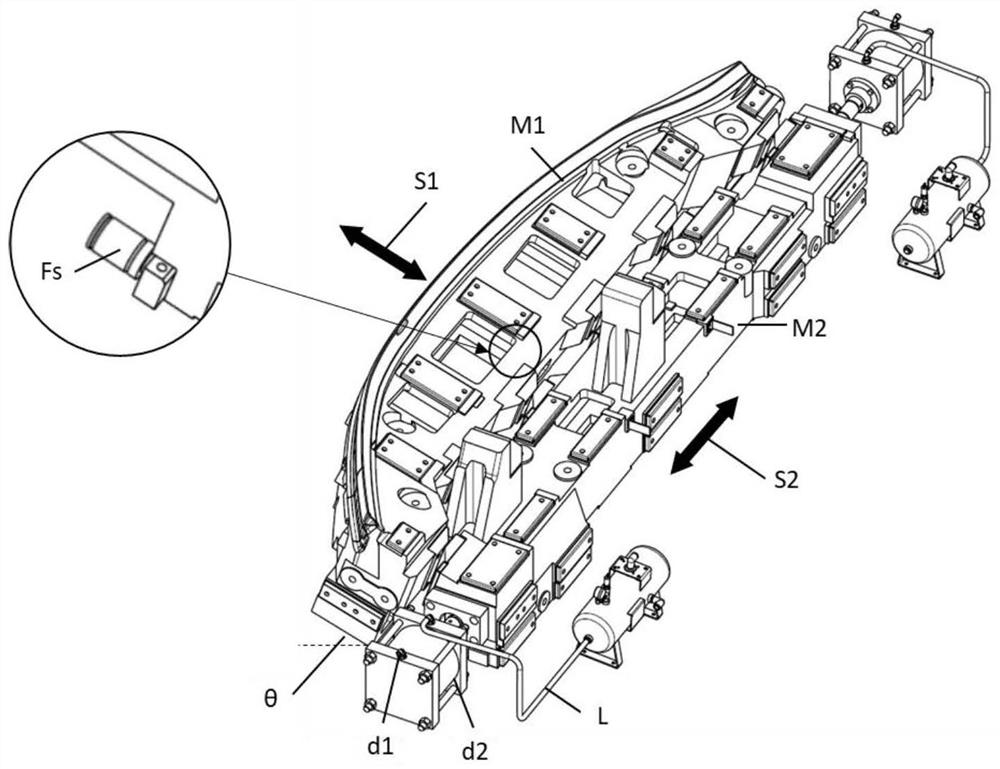

[0082] Some embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

[0083] In the description of the present invention, "module" and "processor" may include hardware, software or a combination of both. A module may include hardware circuits, various suitable sensors, communication ports, memory, and may also include software parts, such as program codes, or a combination of software and hardware. The processor may be a central processing unit, a microprocessor, an image processor, a digital signal processor or any other suitable processor. The processor has data and / or signal processing functions. The processor can be implemented in software, hardware or a combination of both. The non-transitory computer readabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com