Continuous automatic feeding equipment of punching machine

A technology of automatic feeding and punching machine, applied in metal processing equipment, cleaning method using gas flow, feeding device, etc., can solve the problems of poor position accuracy, long process time, low processing efficiency, etc., and reduce processing defects. , The processing process is compact, and the cleaning effect is ensured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

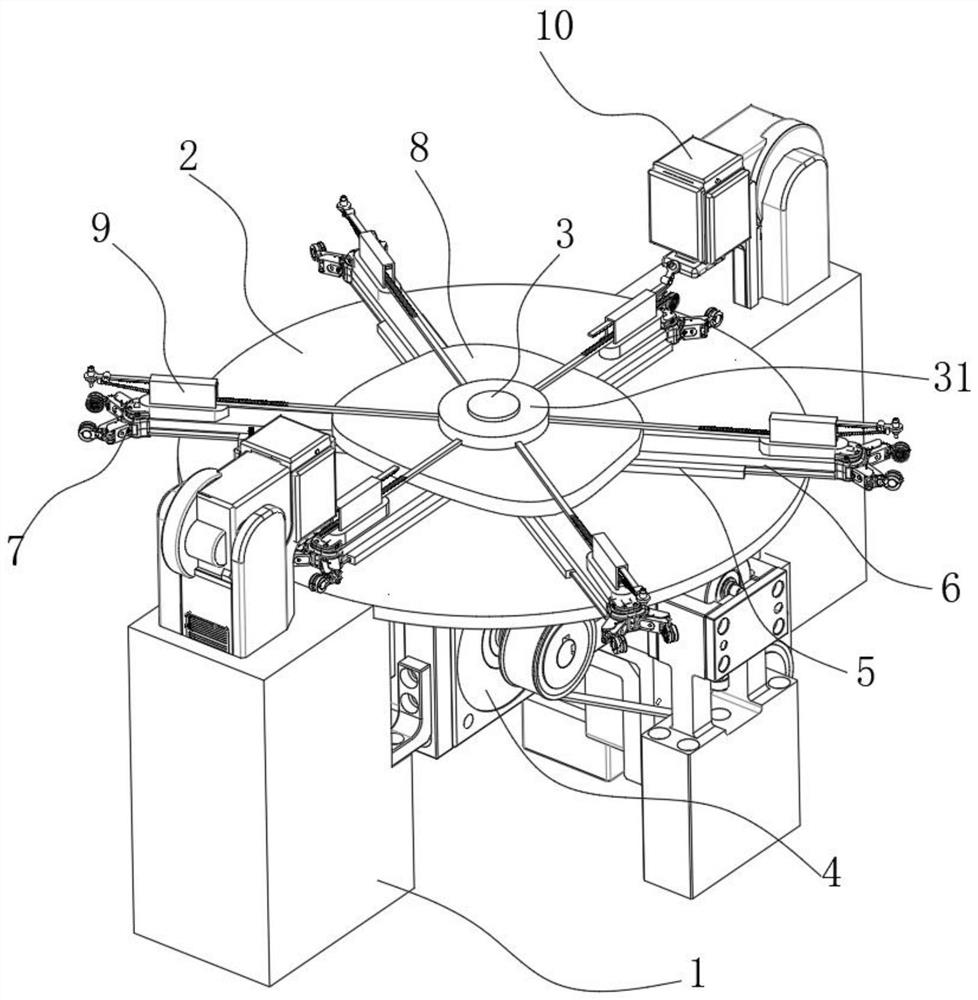

[0025] see figure 1 , in an embodiment of the present invention, a punching machine continuous automatic feeding equipment, including a bracket 1, the center above the bracket 1 is fixed with a central shaft 3, the central shaft 3 is rotatably sleeved with a turntable 2, the The turntable 2 is rotatably connected to the support 1, and the support 1 is provided with a drive device 4, and the drive device 4 can drive the turntable 2 to rotate along the edge of the turntable 2;

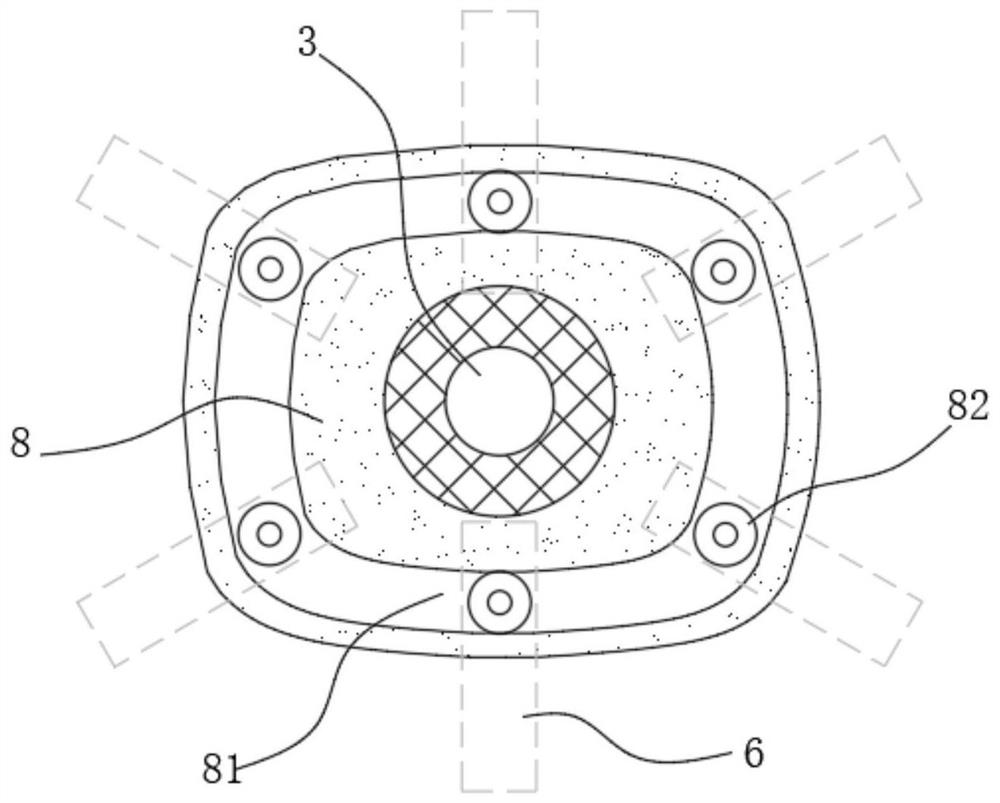

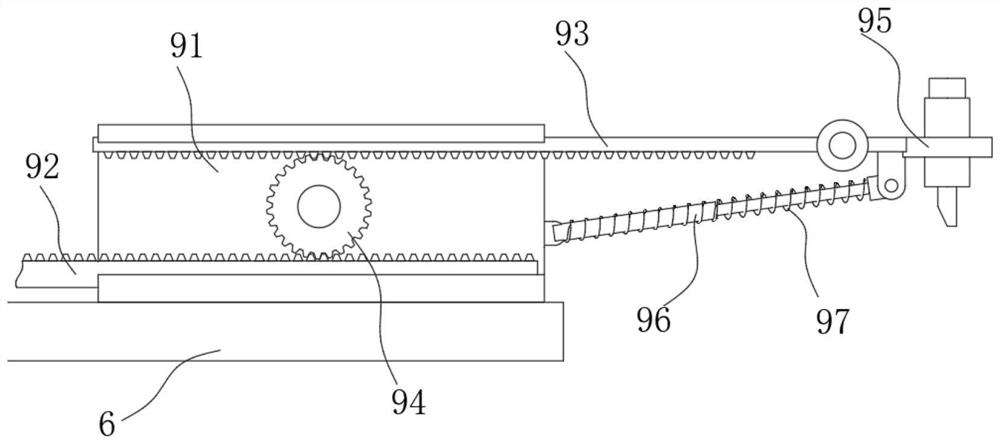

[0026] The upper circumference of the turntable 2 is evenly distributed with a plurality of guide rails 5 extending radially, each of the guide rails 5 is slidably connected with a slide bar 6, and the end of the slide bar 6 away from the center of the turntable 2 is provided with a clip. Holding device 7, the top of described holding device 7 is provided with the cleaning assembly 9 that is fixed on the slide bar 6;

[0027] At least one punching machine 10 is provided on the edge of the turntable 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com