Quick positioning multi-airflow beam coupling device for assisting welding process

A technology of auxiliary welding and coupling device, applied in auxiliary devices, auxiliary welding equipment, welding equipment and other directions, can solve the problems of difficult and flexible adjustment, limited effect of welding quality improvement, and achieve the effect of reducing spatter, flexible adjustment and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0043] The invention aims at welding defects such as spatter and air holes that affect the welding quality in the welding process, and the traditional single gas flow assisting welding process has limited effect and difficult to adjust the position of action accurately and flexibly, and provides a fast and flexible auxiliary welding process Position the multi-stream coupling.

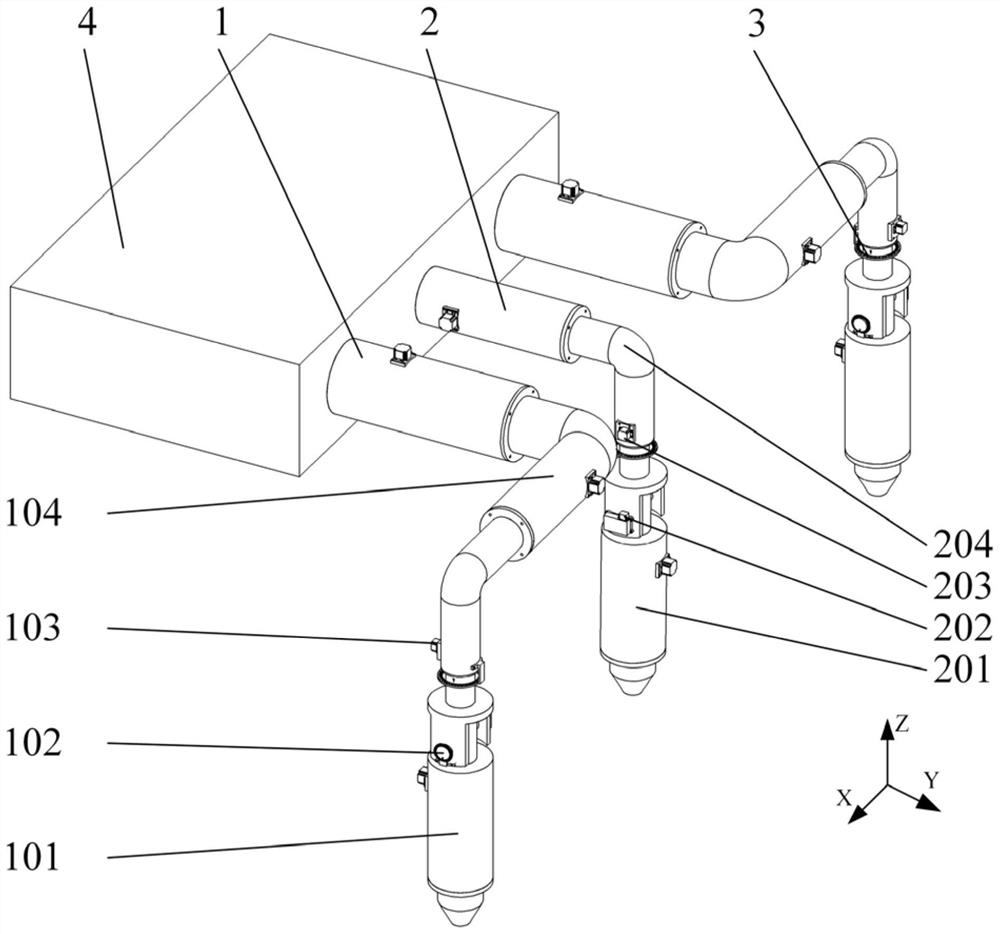

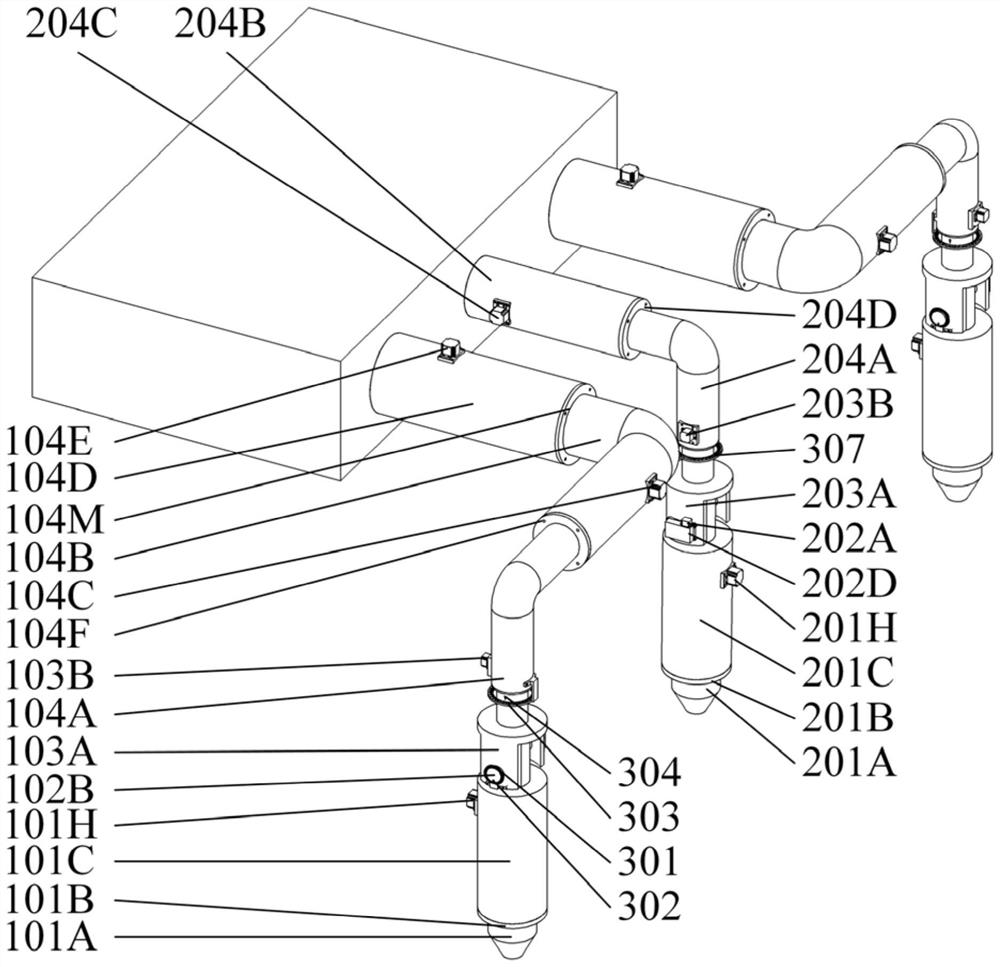

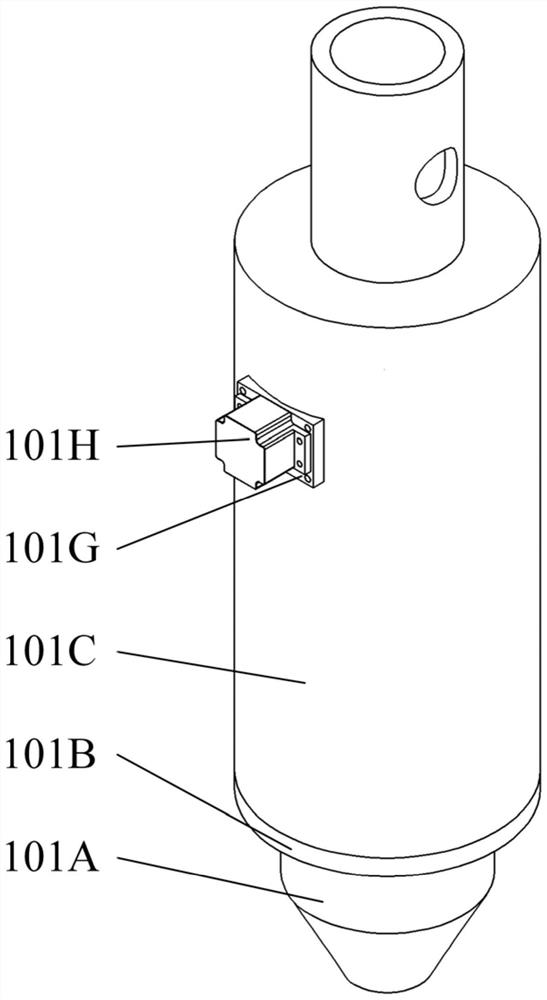

[0044] Such as figure 1 with figure 2As shown, the embodiment of the present invention provides a kind of fast positioning multi-air flow beam coupling device for assisting welding process, including: two groups of side air flow beam devices 1, middle air flow beam device 2, indicator device 3 and multiple air flow beams Combined device 4, two groups of side air beam devices 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com