Excess material cutting equipment with smooth notch based on environment-friendly plastic

A technology of environmentally friendly plastics and cutting equipment, which is applied in metal processing and other directions, can solve the problems of poor accuracy and inability to ensure the incision of environmentally friendly plastic plates, and achieve the effects of ensuring effectiveness, facilitating maintenance, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

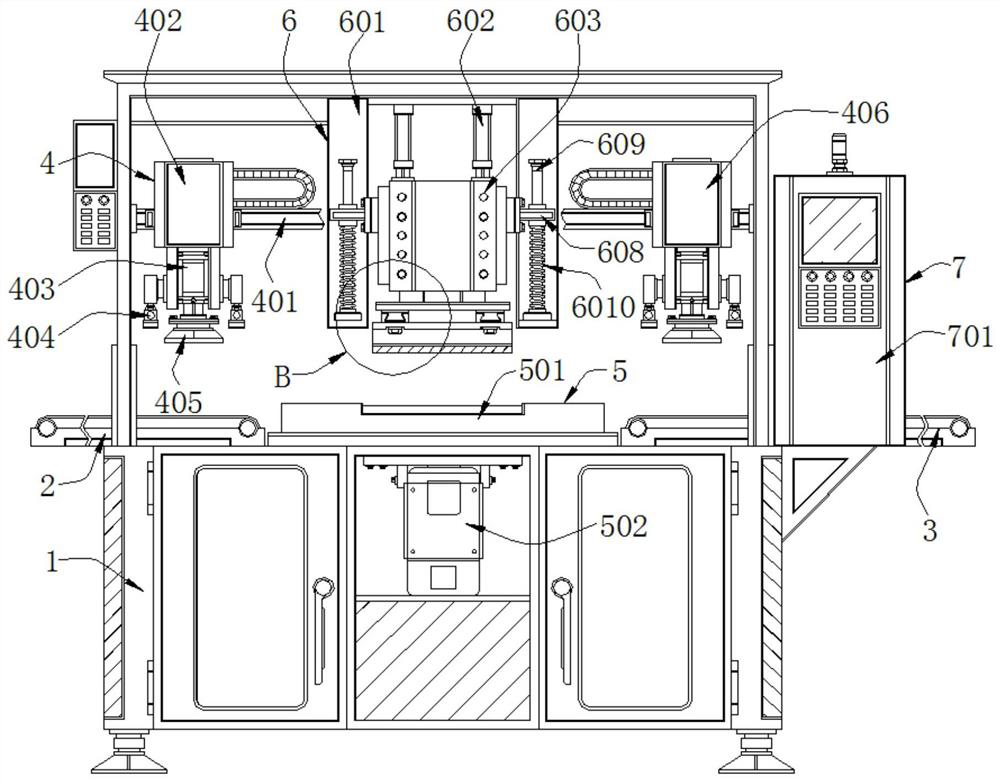

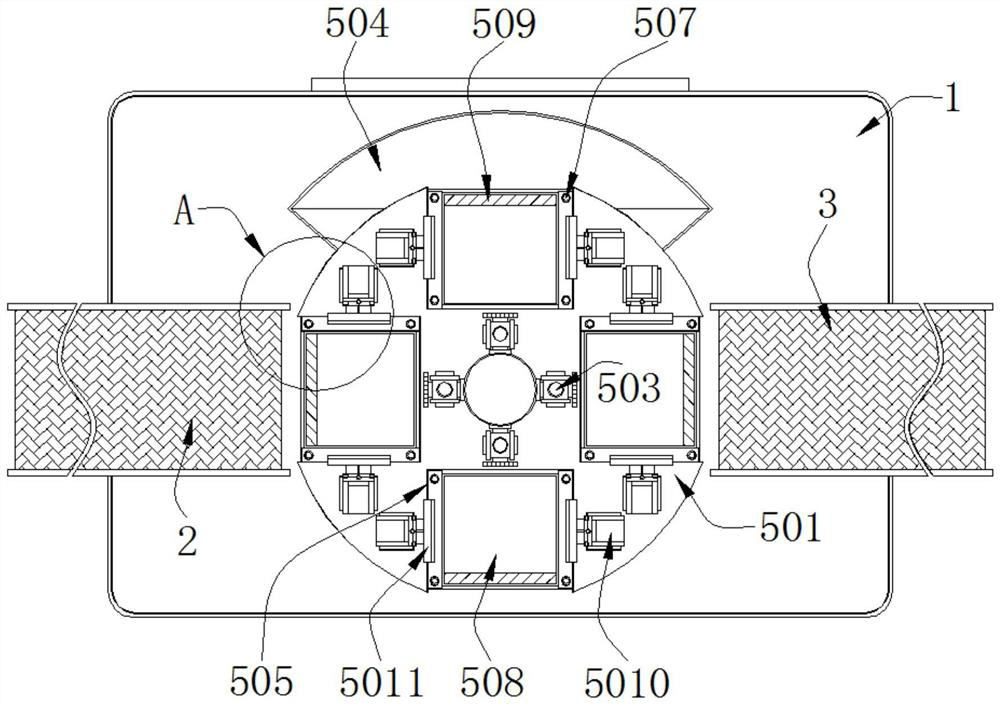

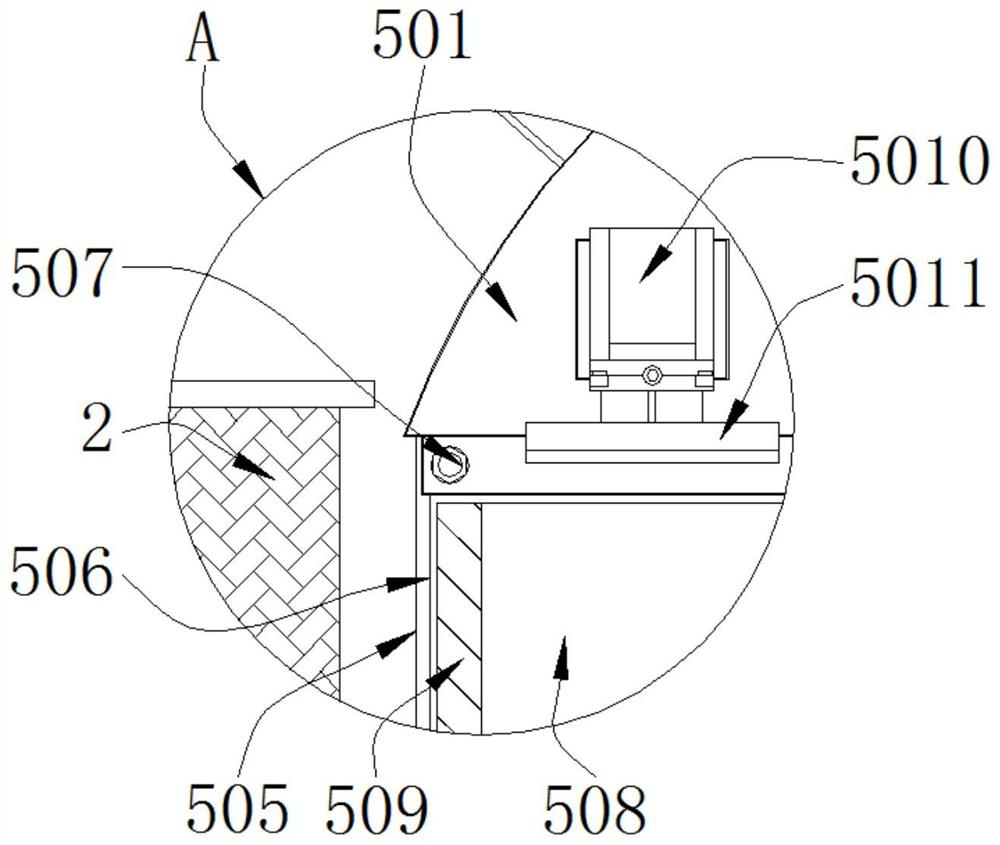

[0027] see Figure 1-5, the present invention provides a technical solution: a kind of waste material cutting equipment based on environmentally friendly plastics, including a settling seat 1 and a cutting assembly 6, a feeding conveyor belt 2 is provided on the left side of the upper end of the settling seat 1, and the settling seat The right side of the upper end of 1 is provided with a feeding conveyor belt 3, and the upper and lower sides of the seat 1 are provided with a feeding assembly 4 for plastic loading and unloading, and the center of the upper end of the seat 1 is provided with a transfer assembly 5 for plastic transfer. The cutting assembly 6 for cutting the plastic residue is distributed behind the upper end of the transfer assembly 5, and the cutting assembly 6 includes a fixed seat 601, a driving cylinder 602, a cutting head 603, a placement slide rail 604, a placement slide block 605, a cutting blade 606, a fixed Bolt 607, connecting ring 608, limit rod 609 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap