Full-recycled aggregate concrete and preparation method thereof

A technology of recycled aggregate and recycled coarse aggregate, applied in the field of concrete, can solve the problems of poor work performance and durability, low strength, etc., and achieve the effect of excellent work performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

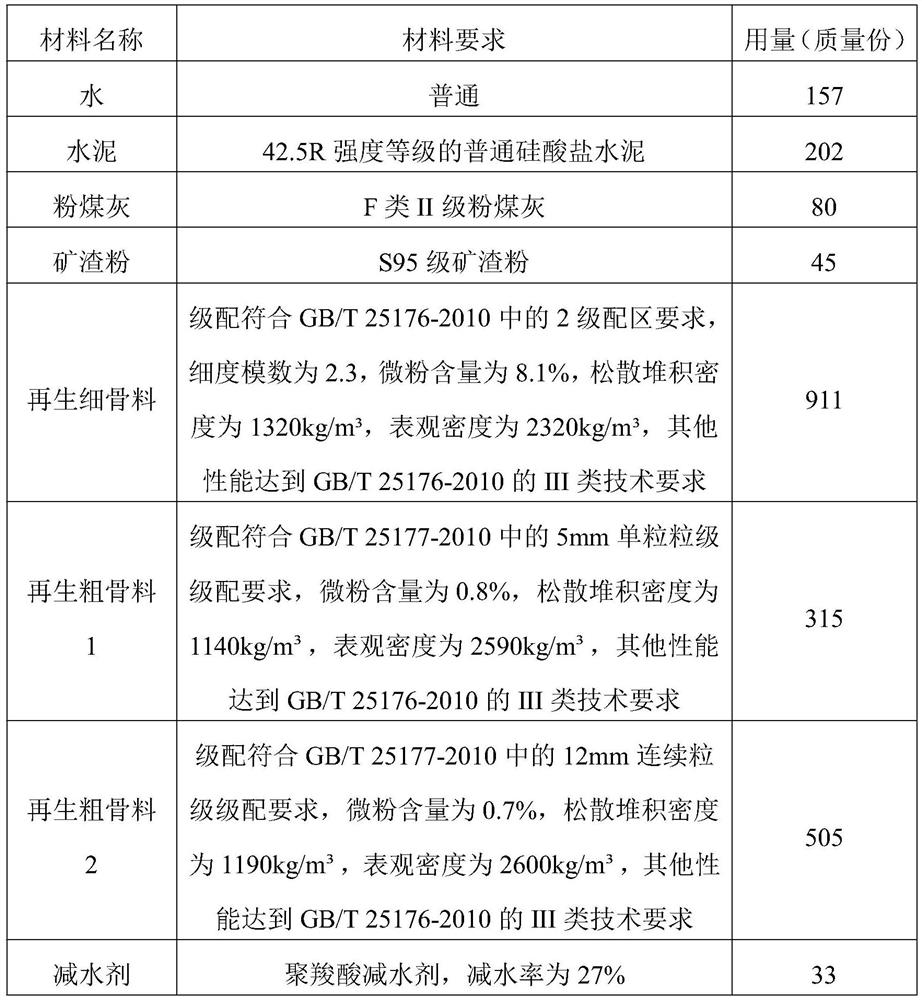

Embodiment 1

[0017]

[0018] The concrete preparation method of embodiment 1 is as follows:

[0019] Add the above-mentioned raw materials, except additives, into a mixing container according to a certain ratio, and pre-stir evenly, then add additives and water and stir for 5 minutes, then let stand for 5 minutes, and finally stir for 3 minutes to obtain concrete.

[0020] The concrete performance of embodiment 1 is as follows:

[0021]

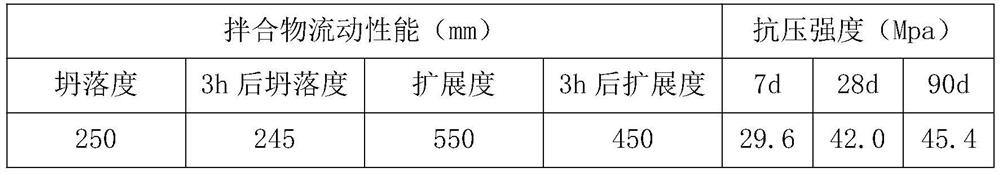

Embodiment 2

[0023]

[0024] The concrete preparation method of embodiment 2 is as follows:

[0025] Add the above-mentioned raw materials, except additives, into a mixing container according to a certain ratio and pre-stir evenly, then add additives and water and stir for 2 minutes, then let stand for 3 minutes, and finally stir for 5 minutes to obtain concrete.

[0026] The concrete performance of embodiment 2 is as follows:

[0027]

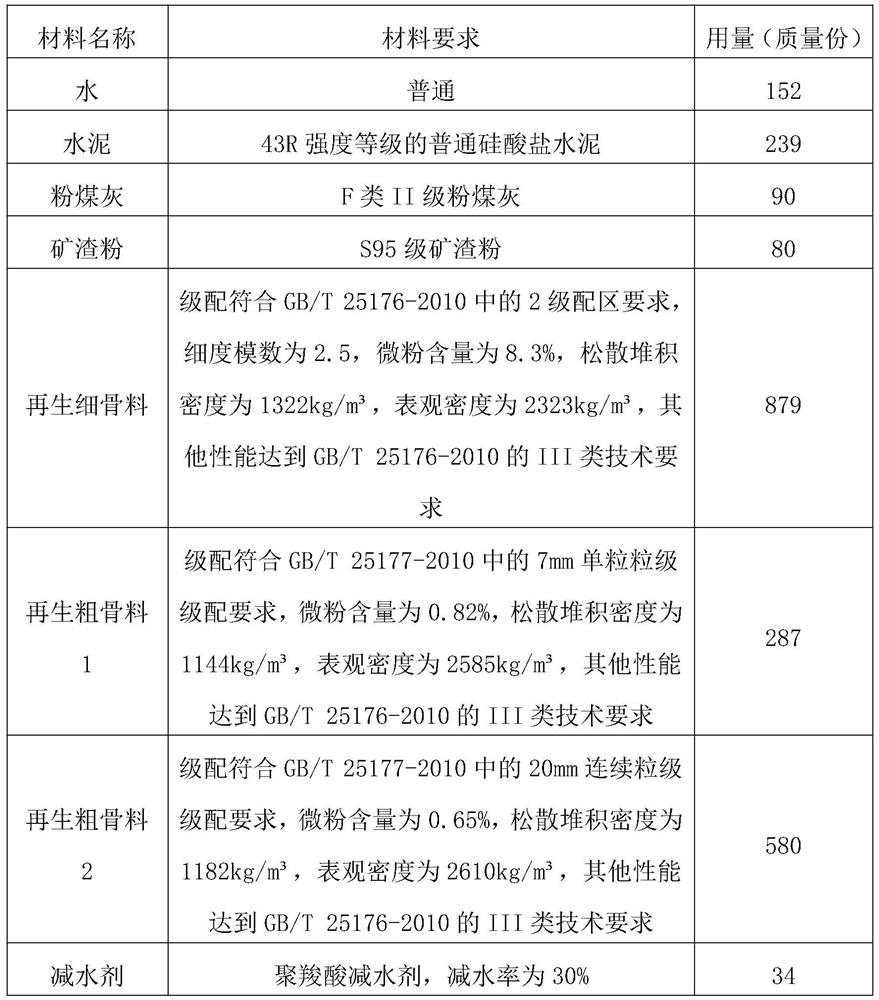

Embodiment 3

[0029]

[0030] The concrete preparation method of embodiment 3 is as follows:

[0031] Add the above-mentioned raw materials, except additives, into a mixing container according to a certain ratio and pre-stir evenly, then add additives and water and stir for 5 minutes, then let stand for 5 minutes, and finally stir for 5 minutes to obtain concrete.

[0032] The concrete performance of embodiment 3 is as follows:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com