High-gloss antibacterial PLA material for 3D printing and preparation method of high-gloss antibacterial PLA material

A 3D printing, high-gloss technology, applied in the field of polyolefin materials, can solve the problems of unfavorable PLA environment, high cost of antibacterial agents, complex processing raw materials, etc., to achieve the effect of improving diversified performance, improving gloss, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

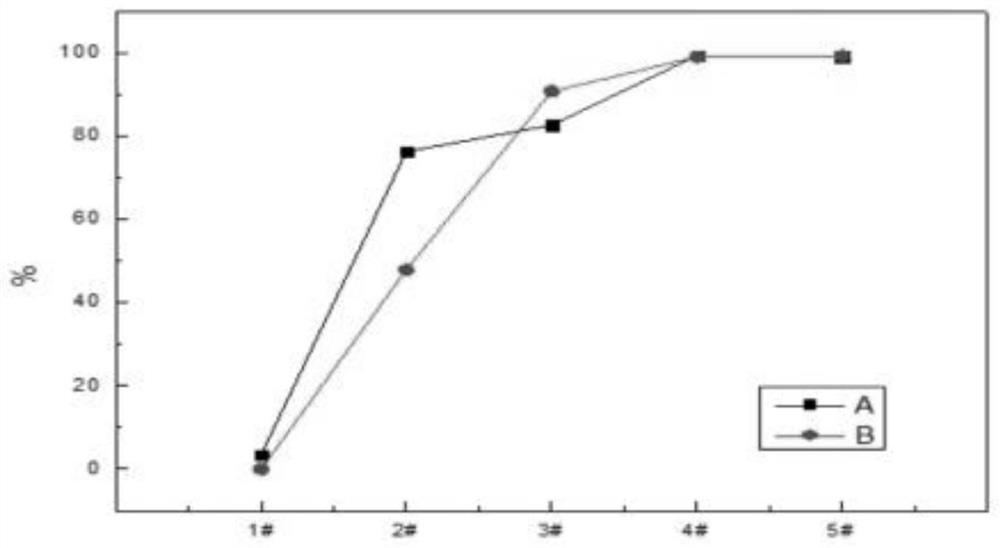

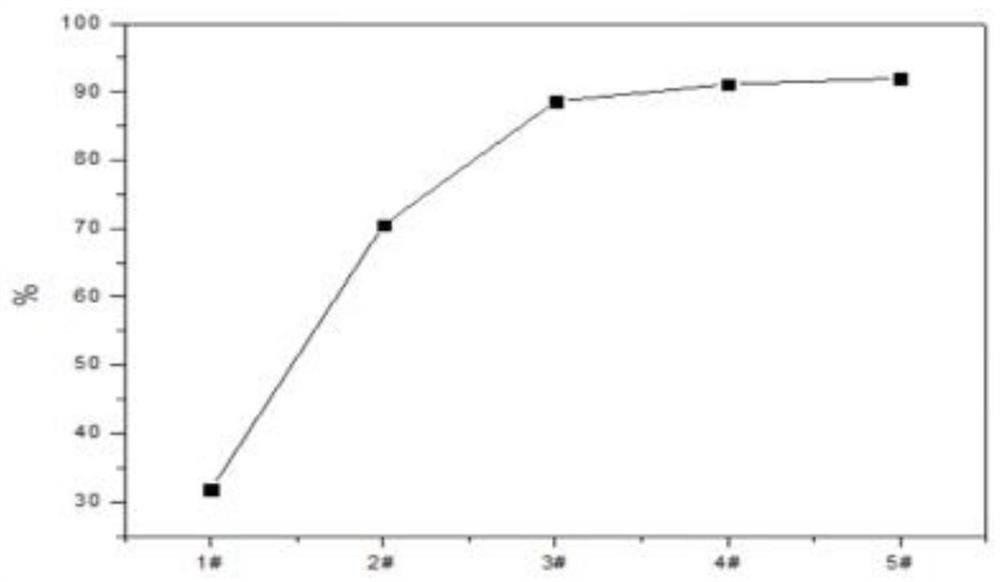

Examples

Embodiment 1

[0036] A high-gloss antibacterial PLA material for 3D printing and a preparation method thereof, comprising the following components by weight:

[0037] 100 parts of PLA resin base material, 3 parts of compatibilizer, 0.05 part of antioxidant, 0 part of antibacterial agent, 0 part of brightener

[0038] Dry the PLA resin base first, and expose it to the air for more than 1 hour, or dry it in an oven at 80°C for 30 minutes.

[0039] Put the base material and modifier into a high-speed mixing box and mix for 10 minutes.

[0040] Cylinder temperature: barrel zone 185°C, screw zone 210°C, die head zone 200°C.

[0041] The current of the twin-screw host of the extruder is controlled at 8A.

[0042] The homogeneously mixed raw materials are heated by an extruder, extruded, pelletized, and dried to obtain 3D printing materials.

Embodiment 2

[0044] 100 parts of PLA resin base material, 3 parts of compatibilizer, 0.05 part of antioxidant, 0.1 part of antibacterial agent, 0.02 part of brightener;

Embodiment 3

[0046] 100 parts of PLA resin base material, 3 parts of compatibilizer, 0.05 part of antioxidant, 0.2 part of antibacterial agent, 0.04 part of brightener;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com