Overwater large-span tied-arch bridge girder dismantling structure and dismantling construction method

A technology of tied arch bridge and construction method, applied in the direction of bridges, bridge parts, bridge maintenance, etc., can solve the problems of high safety risk, many investment personnel, damage to surrounding traffic roads, etc., and achieves less environmental pollution and stable beam separation. , the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

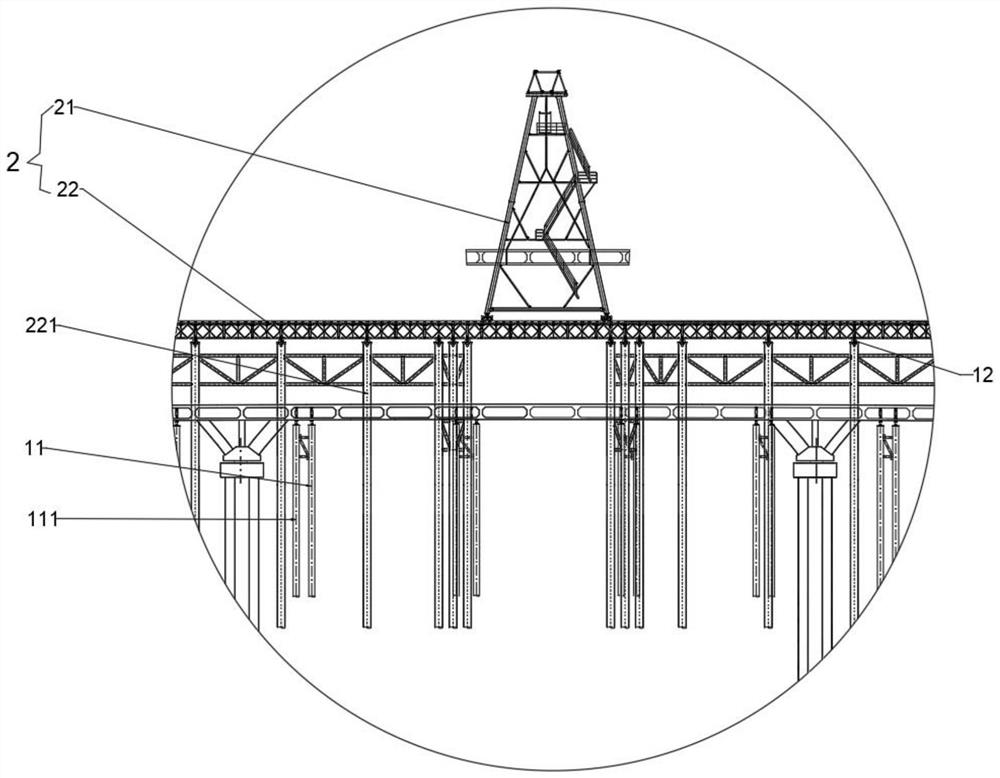

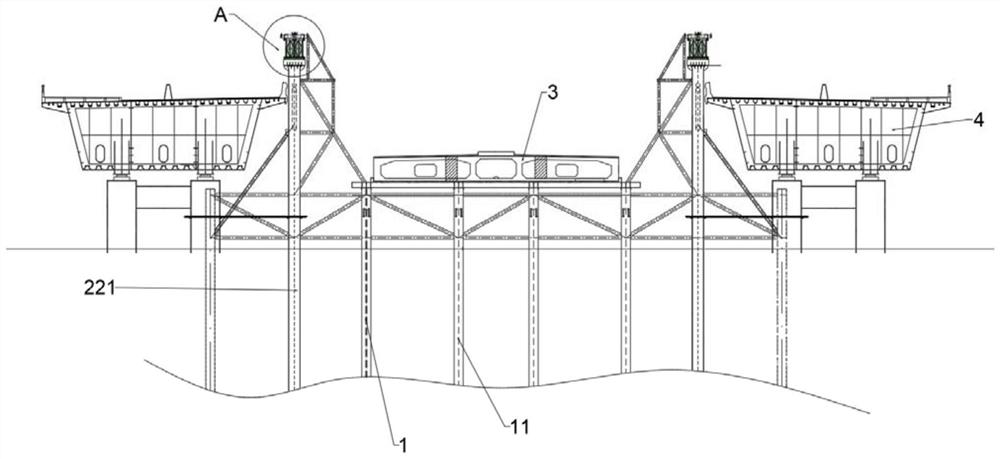

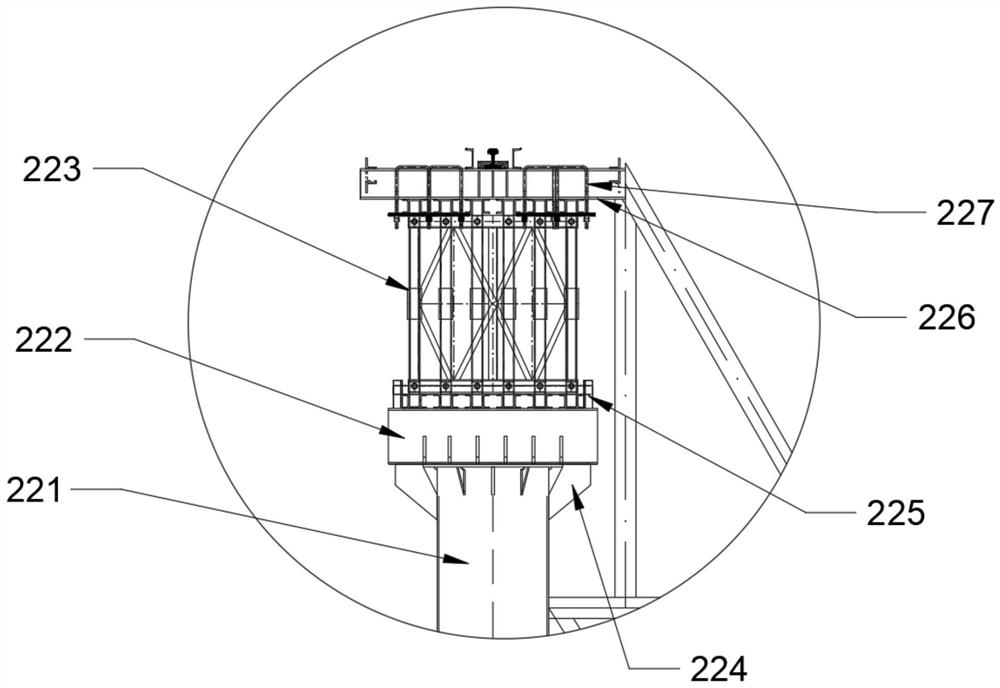

[0028] As shown in the figure, this embodiment provides a structure for dismantling the main girder of a large-span tied arch bridge over water, including a main girder load-bearing system 1 and a main girder lifting system 2, and the main girder lifting system is arranged between the main girder 3 and the auxiliary bridge 4 of the arch bridge The main beam load-bearing system 1 includes 12 groups of steel pipe supports 11, and the 12 groups of steel pipe supports 11 are arranged on both sides of the arch bridge main beam 3, and are symmetrical about the arch bridge main beam 3, so that the arch bridge main beam 3 is divided into 13 spans, and the steel pipe supports 11 The top is paved with a supporting base 12; the main girder lifting system 2 includes a water gantry crane 21 and a gantry crane tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com