Rice crust frying equipment with stir-frying function

The utility model relates to a technology of rice cooker and function, which is applied to the field of fried food production equipment, and can solve the problems of low production efficiency and insufficient crispness of rice cooker, and achieve the effects of improving production efficiency, improving taste and prolonging use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

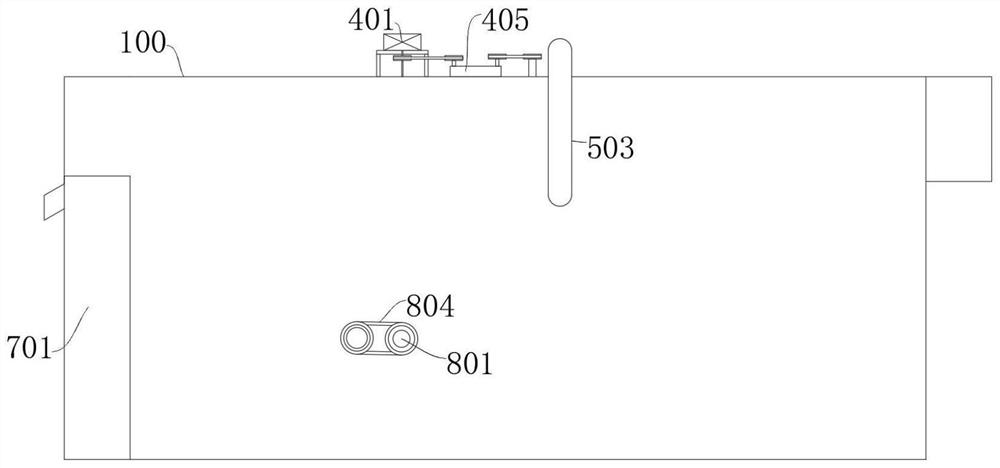

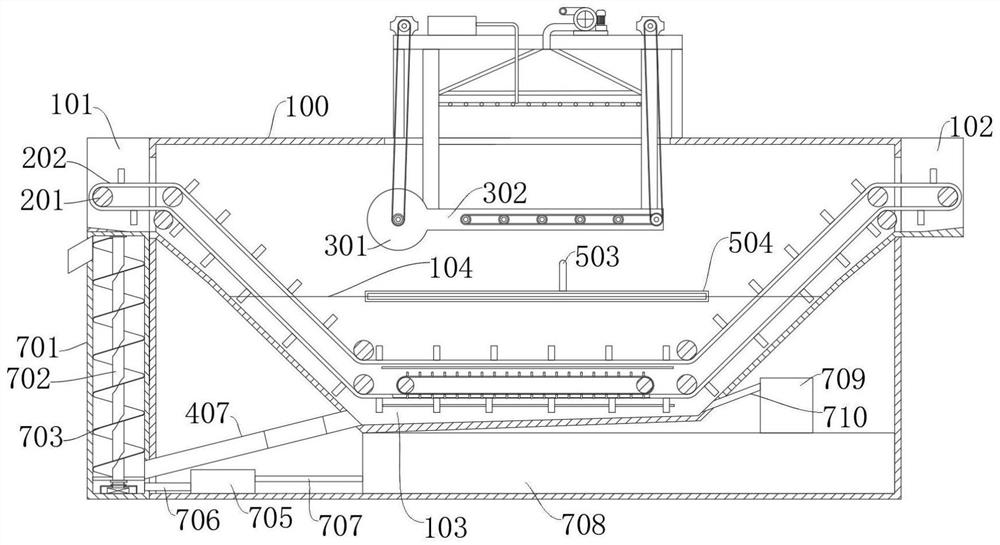

[0036] Embodiment one: refer to figure 1 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 11 , Figure 12 , a crispy rice frying device with stir-frying function, comprising an installation box 100, the installation box 100 is provided with a frying tank 103 for frying the crispy rice, and the side wall of the frying tank 103 is fixedly connected with a An electric heater 1031 for heating; the installation box 100 is provided with a transmission mechanism, and the transmission mechanism is used to receive the crispy rice at the feed inlet 101 of the installation box 100, and send the crispy rice into the frying tank 103 for frying and frying Fried crispy rice is discharged from the installation box 100 from the discharge port 102 of the installation box 100; a mounting frame is arranged in the frying tank 103, and a second mounting shaft 305 is rotatably connected to the mounting frame, and the second mounting shaft 305 is fixedly connected to a useful The turni...

Embodiment 2

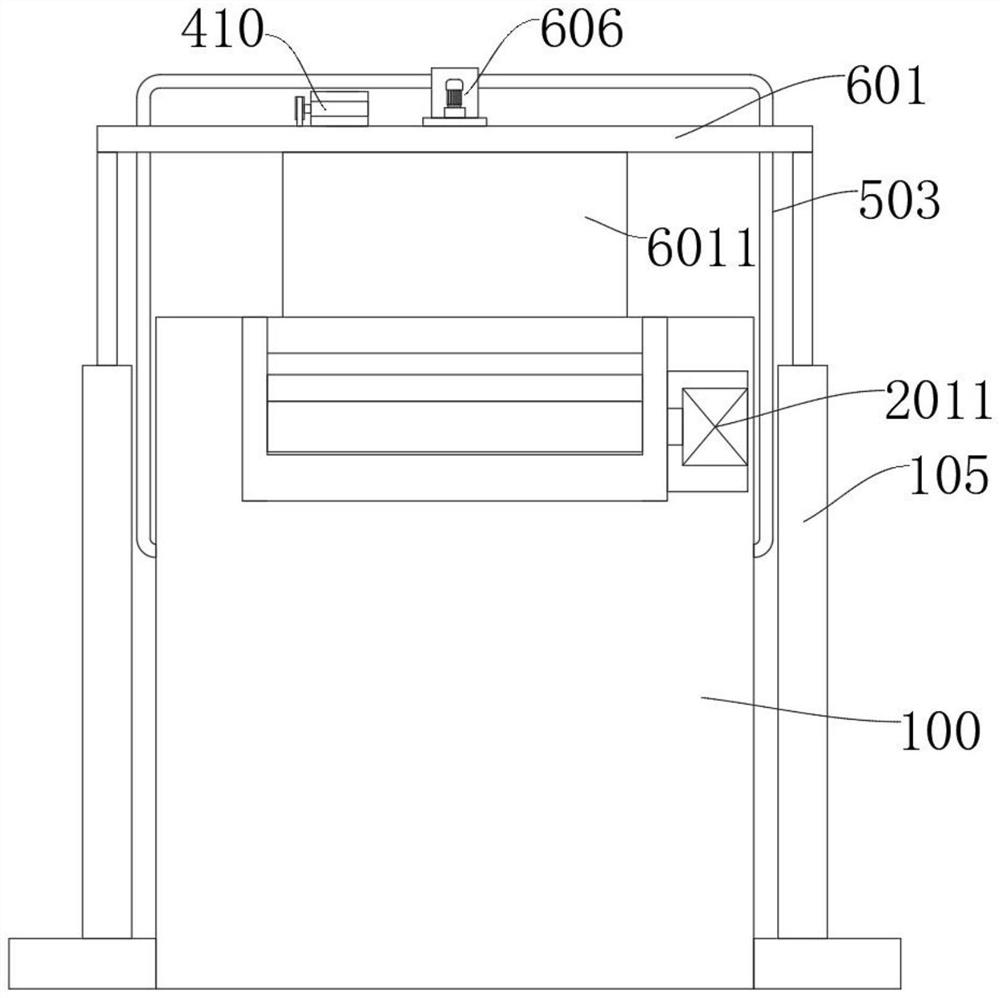

[0044] Embodiment two: refer to figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 , Figure 10 , Figure 11 , Figure 12, a crispy rice frying device with stir-frying function, comprising an installation box 100, the installation box 100 is provided with a frying tank 103 for frying the crispy rice, and the side wall of the frying tank 103 is fixedly connected with a An electric heater 1031 for heating; the installation box 100 is provided with a transmission mechanism, and the transmission mechanism is used to receive the crispy rice at the feed inlet 101 of the installation box 100, and send the crispy rice into the frying tank 103 for frying and frying Fried crispy rice is discharged from the installation box 100 from the discharge port 102 of the installation box 100; a mounting frame is arranged in the frying tank 103, and a second mounting shaft 305 is rotatably connected to the mounting frame, and the second mounting shaft 305 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com