Method for anchor bolt construction by double sleeve

A technology of bolt construction and double casing, which is applied in the directions of bolt installation, earthwork drilling, infrastructure engineering, etc., can solve the problems of high cost, long construction period, poor safety, etc., so as to reduce construction cost, shorten construction period and improve construction. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

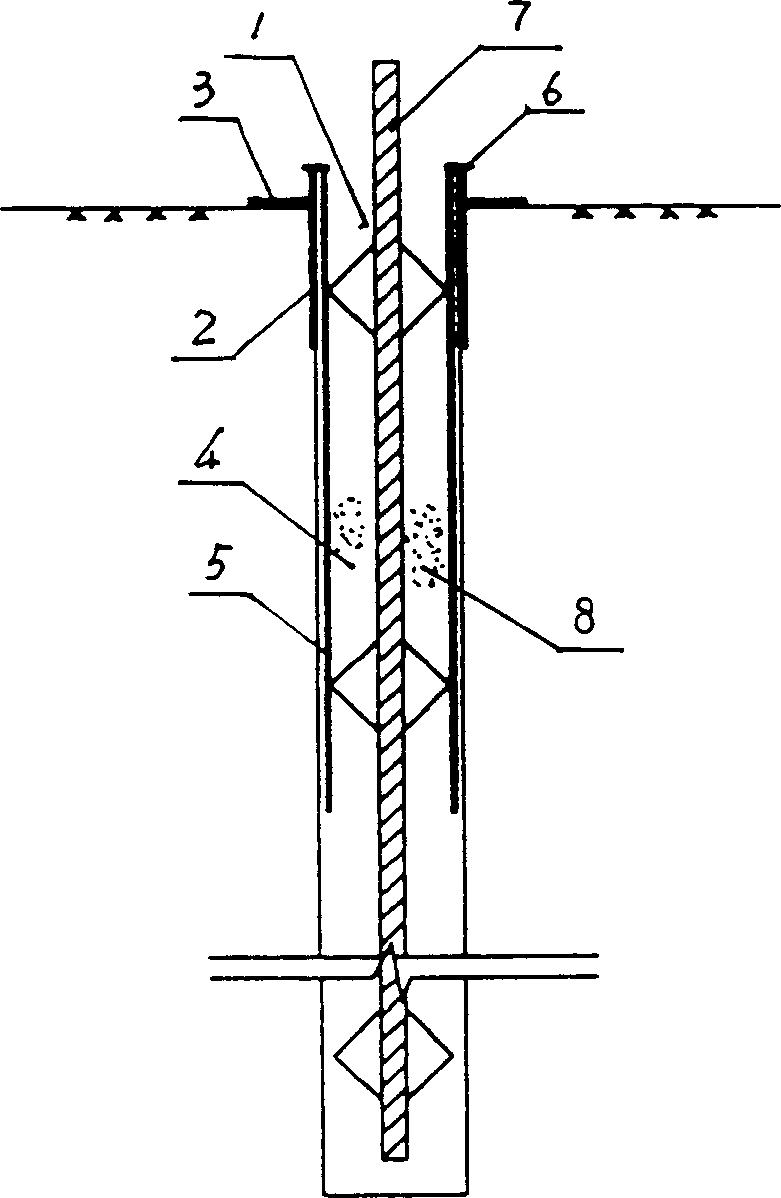

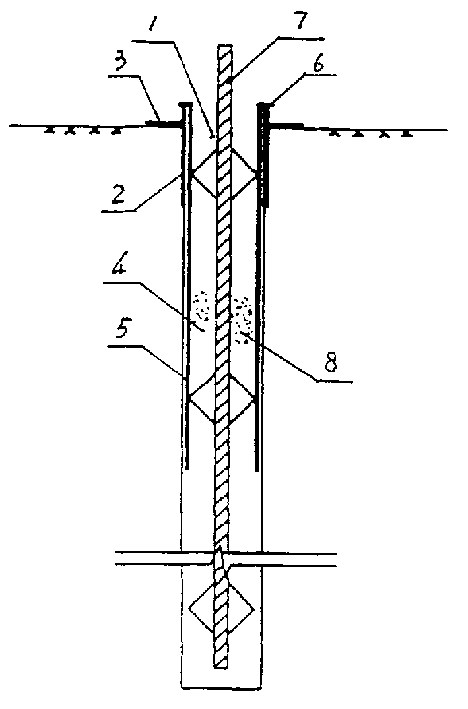

[0014] The construction schematic diagram of the inventive method is as figure 1 As shown, first use a drill bit larger than the design diameter of the bolt to percussion drill a large hole to a certain depth, and drive the outer pipe 2 with an outer diameter smaller than or equal to the diameter of the above-mentioned large hole and an inner diameter larger than the designed diameter of the bolt into the large hole 1. The top of the pipe 2 is 10 to 20 cm above the ground, and then the outer pipe is fixed with the fixing rib 3; use a drilling rig to drill the anchor hole 4 through the outer pipe 3 to the design depth according to the designed hole diameter of the anchor, and in the above-mentioned anchor hole 4 Put in the inner tube 5, the diameter of the inner tube is slightly smaller than the design aperture of the anchor rod, and the insertion depth is slightly deeper than the gravel layer, and the upper end of the inner tube is fixed on the outer tube 2 with a fixed bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com