Ultrasonic-assisted preparation of porous bone cement scaffold and preparation method thereof

An ultrasonic-assisted, porous bone technology, applied in the field of 3D printing and biomedical materials, can solve the problems of inappropriate 3D printing, insufficient contact between materials and body fluids, poor injection performance, etc., to avoid secondary surgery and infection, good mechanical Effects of performance and biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

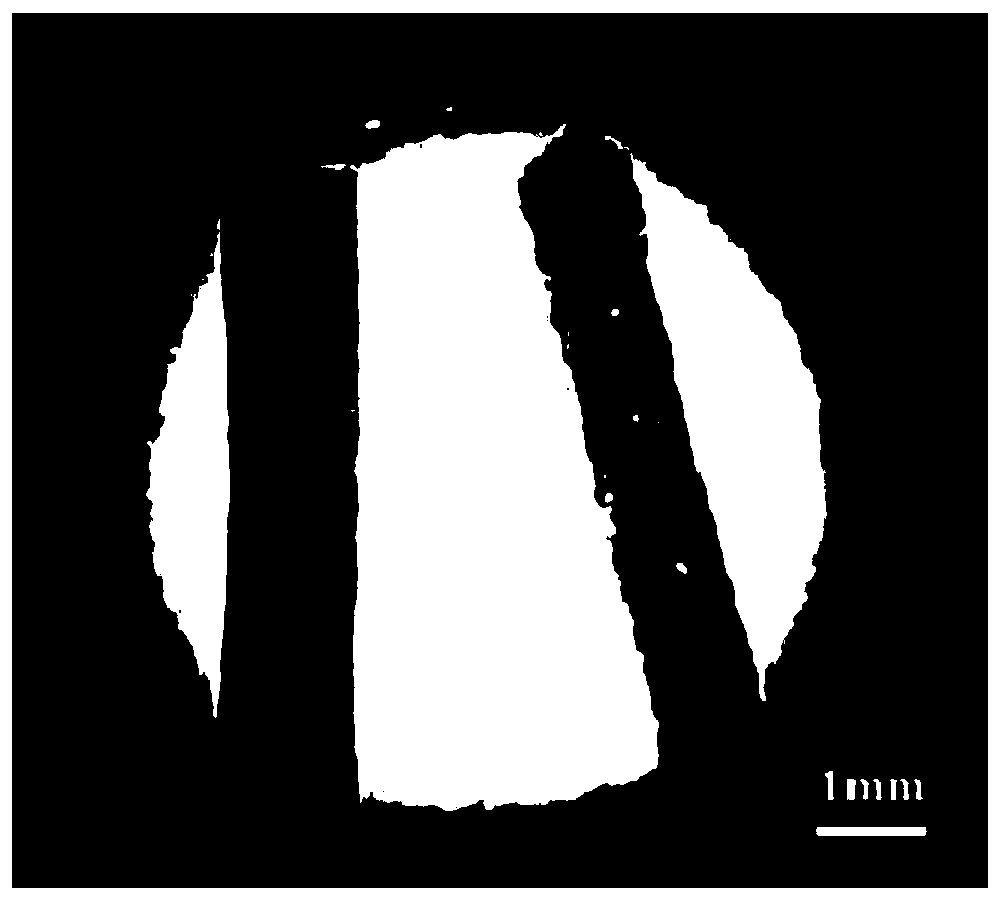

Image

Examples

Embodiment 1

[0021] At 0°C, first add 5% hectorite solution by mass fraction to calcium phosphate powder and mix, then add 4% hydroxypropyl methylcellulose solution (hectorite solution and solidified liquid hydroxypropyl The volume ratio of the methylcellulose solution is 1:1, the ratio of the total liquid volume of the hectorite solution and the solidification solution to the calcium phosphate powder is 1.2mL / g), and the bone cement slurry is obtained by uniform stirring.

[0022] The obtained bone cement slurry was quickly transferred to an extrusion-type 3D printer, and a coaxial needle (the size of the outer needle was 16G, and the size of the inner needle was 23G) was used for 3D printing. Incubate in a 95% constant temperature and humidity box for 3 days to obtain a three-dimensional bone cement scaffold.

[0023] The above-mentioned three-dimensional bone cement scaffold was soaked in 1% acetic acid solution, and then placed in an ultrasonic cleaner (power 80W) for 6 minutes. After...

Embodiment 2

[0025] At 2°C, first add 4% hectorite solution by mass fraction to calcium phosphate powder and mix, then add 1% gelatin solution to it (volume ratio of hectorite solution and solidification solution is 1:5, lithium The ratio of the total liquid volume of the soapstone solution and the solidification solution to the calcium phosphate powder is 0.8mL / g), and uniformly stirred to obtain a bone cement slurry.

[0026] The obtained bone cement slurry was quickly transferred to an extrusion-type 3D printer, and a coaxial needle (outer needle size 18G, inner needle size 26G) was selected for 3D printing. After printing, it was transferred to a temperature of 30°C and a humidity of Incubate in an 85% constant temperature and humidity box for 7 days to obtain a three-dimensional bone cement scaffold.

[0027] The above-mentioned three-dimensional bone cement scaffold was soaked in 0.5% acetic acid solution, and then placed in an ultrasonic cleaner (power 100W) for 4.5 minutes. After ...

Embodiment 3

[0029] At 10°C, first add 3% hectorite solution by mass fraction to calcium phosphate powder and mix, then add 3% sodium alginate solution by mass fraction (the volume ratio of hectorite solution and solidification solution is 1:3 , the ratio of the total liquid volume of the hectorite solution and the solidification solution to the calcium phosphate powder is 1.5mL / g), and uniformly stirred to obtain a bone cement slurry.

[0030] The obtained bone cement slurry was quickly transferred to an extrusion-type 3D printer, and a coaxial needle (the size of the outer needle was 13G, and the size of the inner needle was 18G) was selected for 3D printing. Incubate in a 90% constant temperature and humidity box for 4 days to obtain a three-dimensional bone cement scaffold.

[0031] The above-mentioned three-dimensional bone cement scaffold was soaked in 2% acetic acid solution, and then placed in an ultrasonic cleaner (power 200W) for 2 minutes. After the treatment is completed, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com