Vacuum brazing process for ATR case

A brazing process and chassis technology, applied in the field of brazing process for forming aluminum alloy ATR chassis, can solve the problems of uneven heating of ATR chassis parts, unmelted brazing material, dimensional deformation, etc. The effect of uniform, reducing strength drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

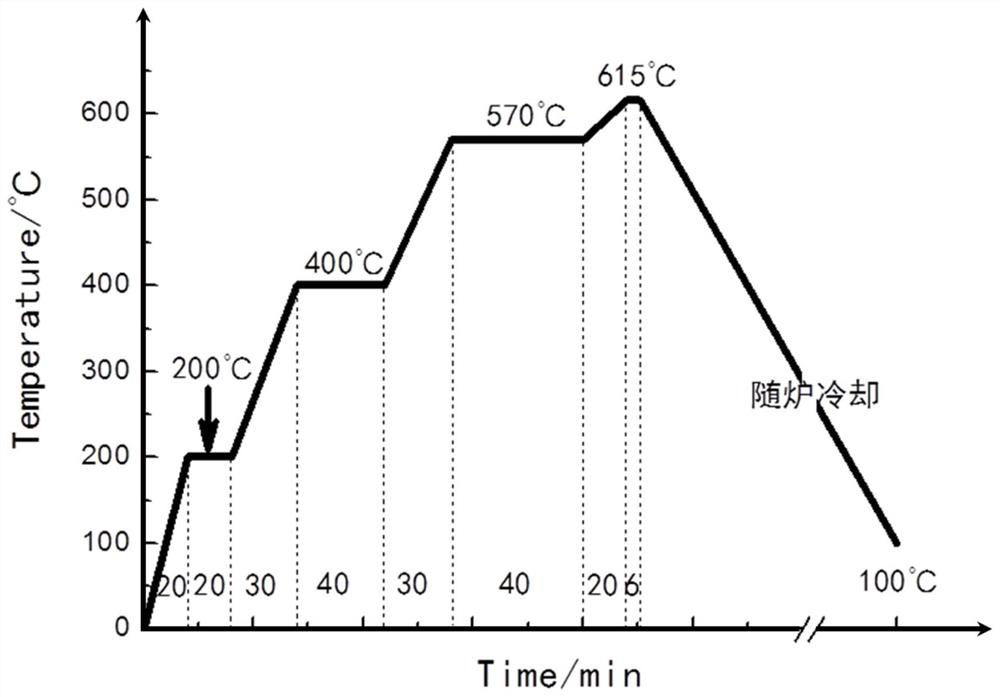

[0023] Chemically clean the components of the aluminum alloy ATR chassis and the solder used, use special tooling to match the assembly position and fix the solder, place it in a ZBS-150 aluminum alloy vacuum brazing furnace, and then carry out vacuum brazing according to the following process :

[0024] 1) Channel confirmation: In this embodiment, implement according to the minimum demand of 3 groups, confirm the number of vacant thermal couple channels in the equipment, and mark the corresponding relationship of the digital display area channels;

[0025] 2) Fix the thermocouples: Use metal wires to fix the first group of thermocouples close to the outer surface of the ATR case, fix the second group of thermocouples close to the inner surface of the ATR case, and fix the third group of thermocouples In the position close to the inner welding seam in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com