Gear rack marking machine

A marking machine and tooth strip technology, which is applied in decorative arts, embossed ornaments, etc., can solve the problems of large manpower demand and low efficiency, and achieve the effects of reducing manpower demand, prolonging service life and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

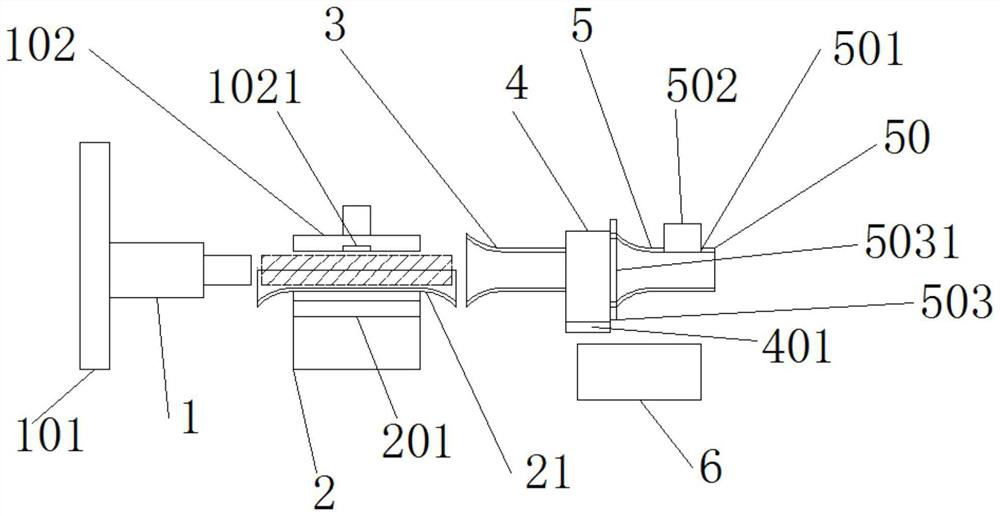

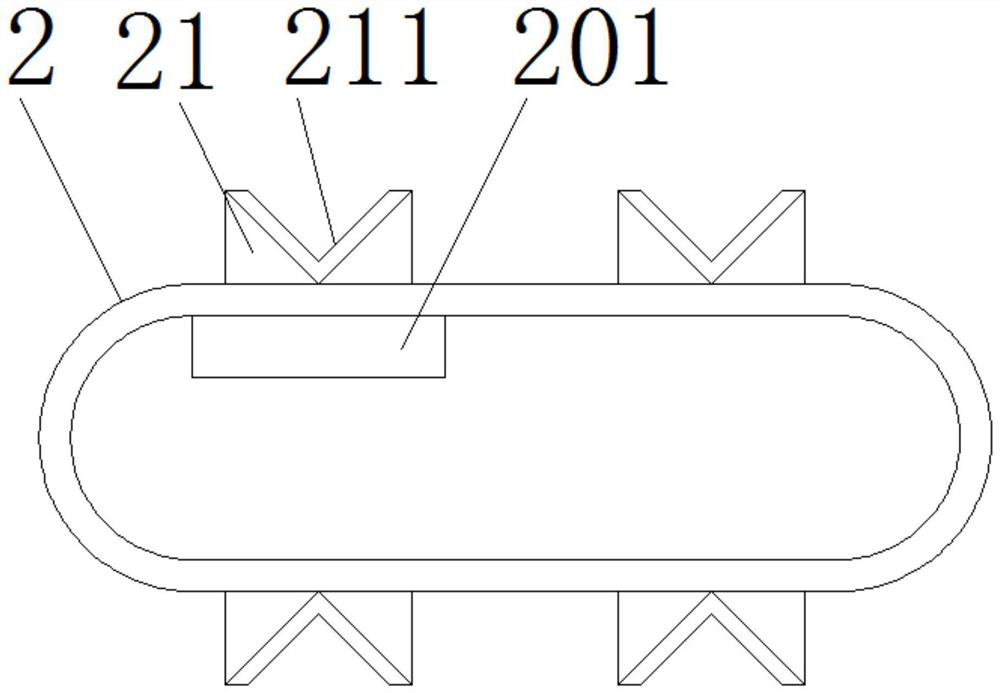

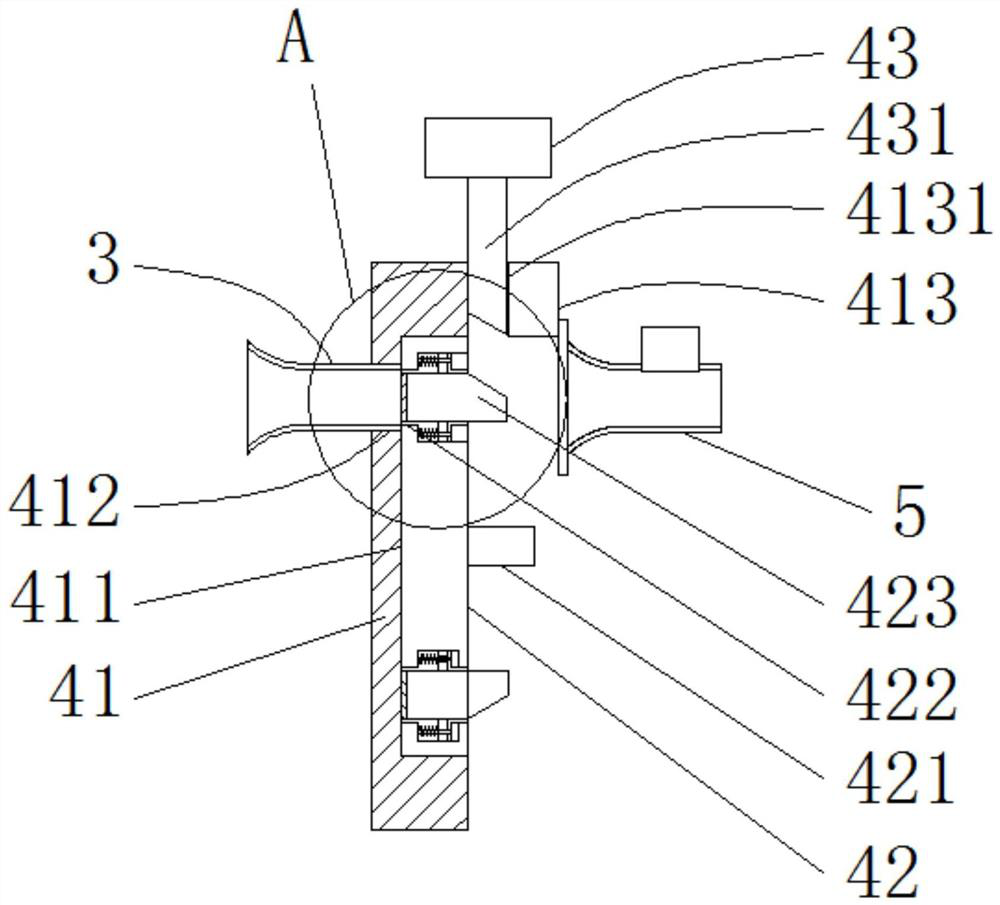

[0019] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5, a tooth bar marking machine of the present invention, comprising a hydraulic rod 1, a conveyor belt 2, a pallet 21, a V-shaped groove 211, a feed pipe 3, a marking device 4, and a discharge pipe 5, and the expansion and contraction of the hydraulic rod 1 The end is horizontally arranged straight to the right, and the right side of the hydraulic rod 1 is provided with a conveyor belt 2, the rotation path of the conveyor belt 2 is perpendicular to the hydraulic rod 1, and several pallets 21 are arranged on the outer surface of the conveyor belt 2, and the upper end surface of each pallet 21 is provided with There are V-shaped grooves 211 arranged in a straight line in the left and right directions, and the V-shaped grooves 211 run through the left and right end faces of the supporting plate 21. The telescopic end on the right side of the hydraulic rod 1 is coaxial, the feed pipe 3 is compatible with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com