Liquid storage tank with reinforcing part and production method of liquid storage tank

A production method and reinforcement technology, applied in the field of liquid storage tanks, can solve the problems of multiple temperature losses of reinforcement materials, long time without heating of the reinforcement layer, etc., and achieve the effects of reduced cooling time, good welding quality, and less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention are described in detail below through the examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present application, and cannot be interpreted as limitations to the technical solutions of the present application.

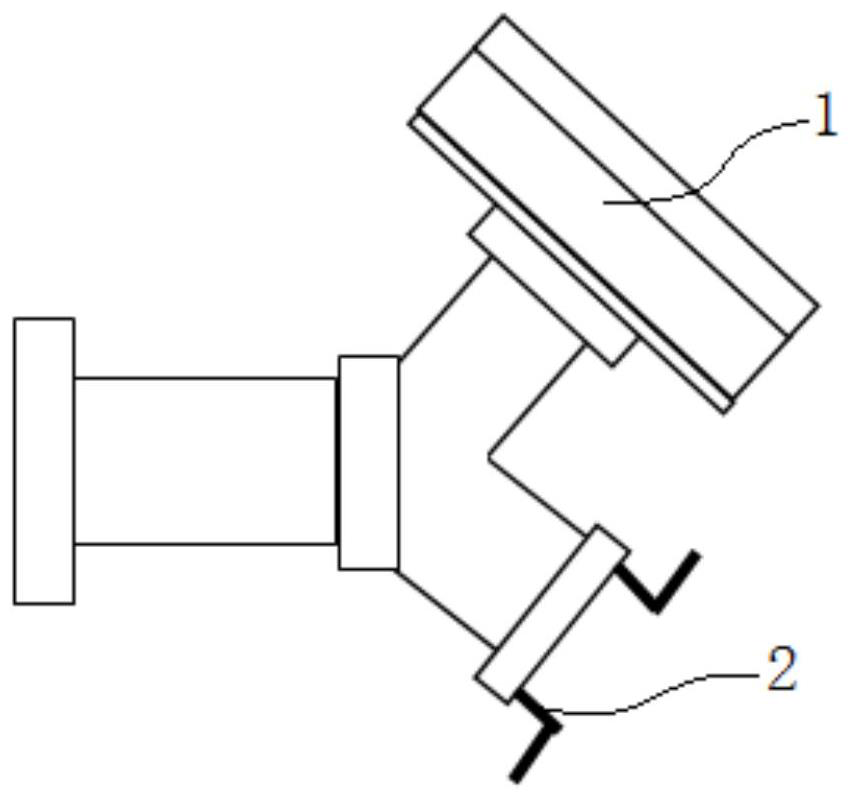

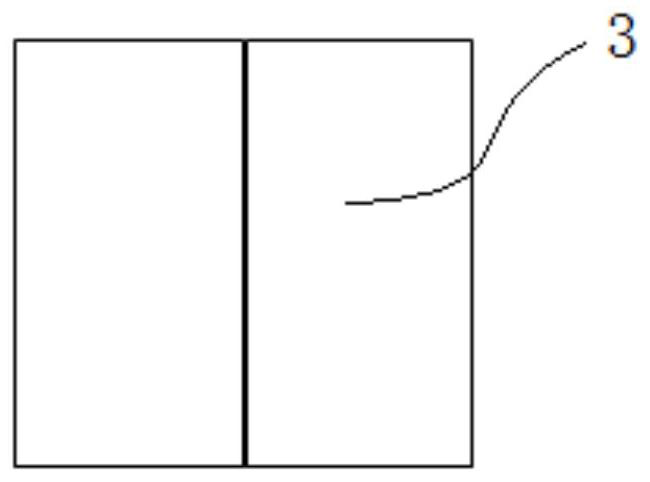

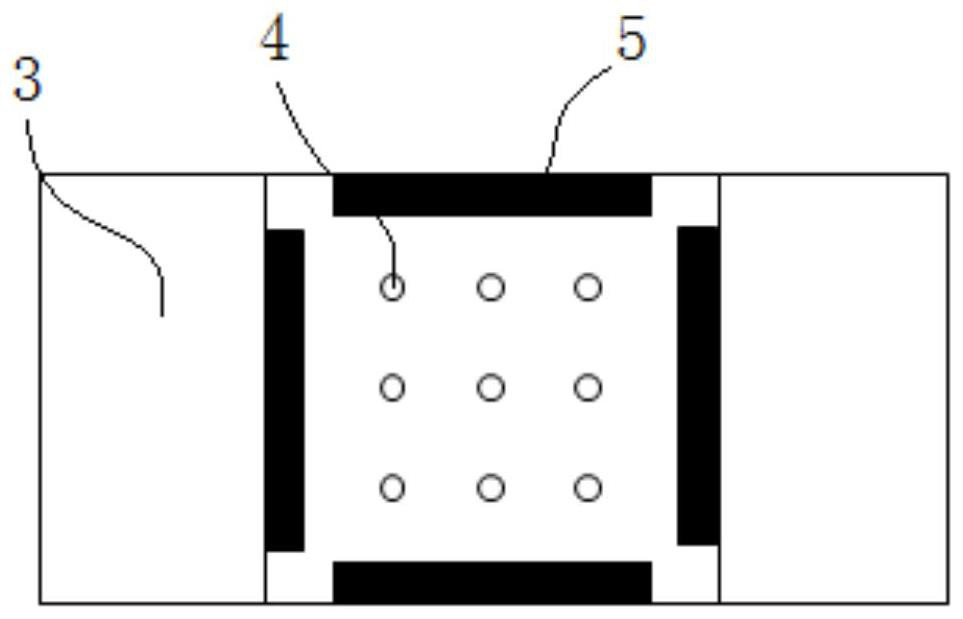

[0040] The present application provides a liquid storage tank with reinforcements. The reinforcements are provided on the surface of the liquid storage tank. In the technical solution of the application, the reinforcements can be provided on the outer surface of the liquid storage tank.

[0041] The material of the reinforcement in this application is made of fiber-containing thermoplastic composite material. The thermoplastic composite material is composed of one or more layers of prepreg, that is, each layer of prepreg contains woven continuous fibers or single-directional non-woven continuous fibers, and the above-mentioned continuou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap