Zinc dross regeneration process

A zinc dross and process technology, applied in the field of multi-purpose comprehensive utilization and regeneration of zinc dross, can solve the problems of inability to fully recover zinc dross, low recovery efficiency, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

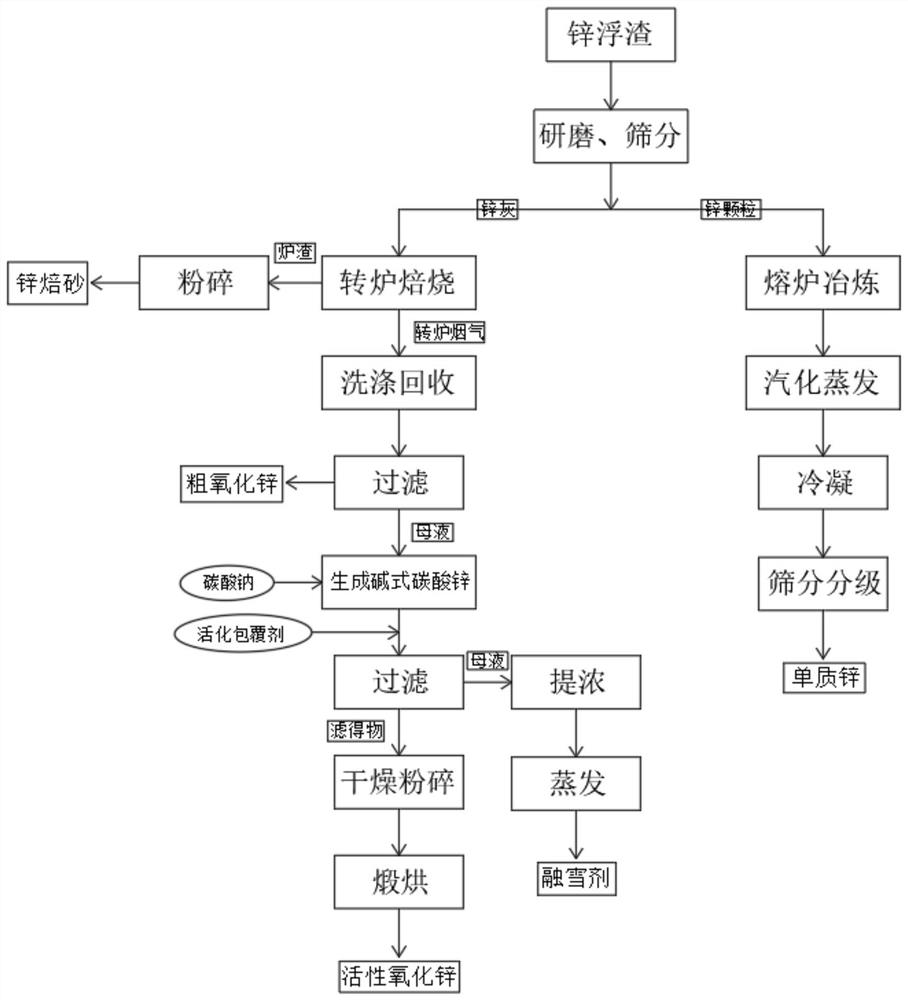

[0028] The following is attached figure 1 , to further illustrate the present invention.

[0029] A kind of zinc scum regeneration process of the present invention, take the zinc scum formed by hot-dip galvanizing and / or electrolytic zinc process as raw material, process according to the following steps:

[0030] S1: Grind and sieve the zinc scum to separate it into zinc particles and zinc ash; the mesh size of the sieve is more than 80 mesh, the sieved zinc particles account for about 35%, and the zinc ash accounts for about 65%;

[0031] S2: Send the zinc particles into the furnace for smelting, feed in natural gas as fuel, and the smelting temperature is 400-500°C;

[0032] S3: Put the zinc ash into the converter for roasting to remove chlorine, feed in natural gas as fuel, and roast at a temperature of 700-800°C to obtain roasting furnace slag and converter flue gas;

[0033] S31: crushing the roasting furnace slag to obtain zinc calcined sand;

[0034] S32: washing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com