Aluminum alloy smelting degassing equipment and degassing method thereof

A degassing equipment and aluminum alloy technology, applied in the field of alloy refining, can solve the problems of trachoma and pores, degassing troubles, uniform distribution of bubbles, etc., and achieve the effect of easy removal and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

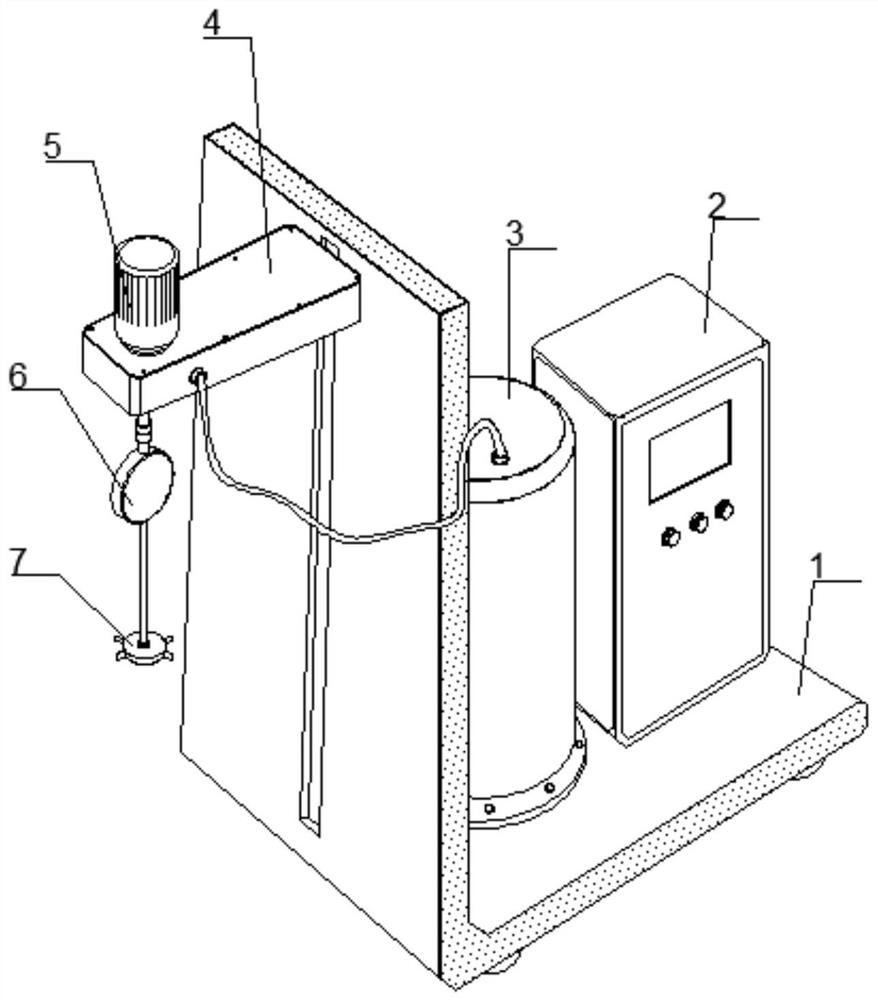

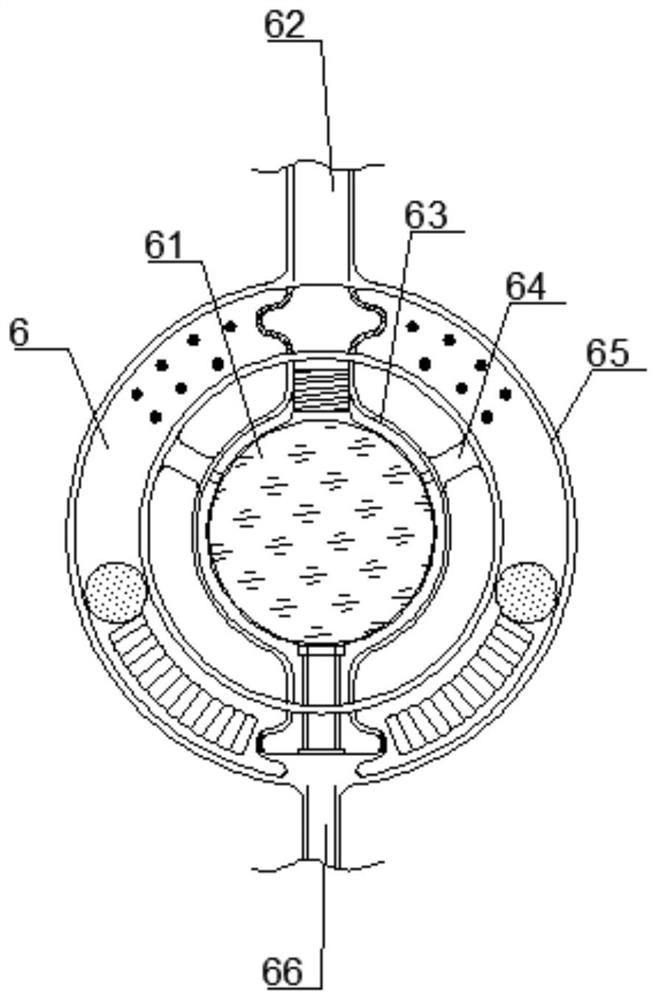

[0030] like Figure 1-2 As shown, the aluminum alloy smelting and degassing equipment includes an L-shaped frame 1 and a track, the side wall of the L-shaped frame 1 is provided with a track, the outer side of the track is provided with a beam 4, and the slider at the beam 4 is inserted into the track; the top of the beam 4 is inserted into the track; A drive unit 5 is fixed, and the drive shaft at the drive unit 5 is protruding relative to the bottom end of the beam 4; a gas treatment device 6 is arranged below the beam 4, and the gas treatment device 6 includes a vibration assembly 65, and a vibration assembly 65 is provided below the transmission shaft. , the top of the vibration assembly 65 is vertically fixed with an inlet pipe 62, and the inlet pipe 62 is connected with the transmission shaft through a coupling; the inner side of the vibration assembly 65 is provided with an annular casing 63, and the two extending ends of the annular casing 63 are connected to the vibrat...

Embodiment 2

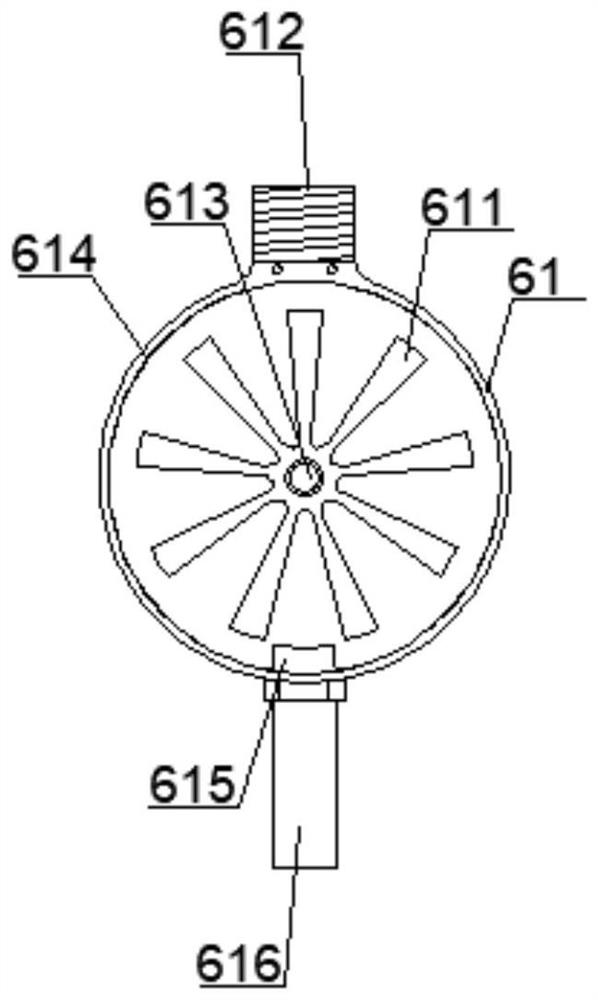

[0035] like figure 2 , 3 As shown in and 5, the aluminum alloy smelting and degassing equipment, the bubble generator 61 includes an impeller 611, a shunt 612, a mandrel 613, a round box 614, a socket 615 and a cannula 616, and the annular casing 63 is sleeved with a round box 614, An annular gap is formed between the outer wall of the round box 614 and the inner wall of the annular casing 63; the upper end of the round box 614 is fixedly connected with a shunt pipe 612, and the shunt pipe 612 is inserted into the overhanging end set above the annular casing 63; the bottom end of the round box 614 penetrates through A socket 615 is embedded, and an intubation tube 616 is sleeved and fixed at the protruding head of the socket 615. The intubation tube 616 is inserted into the protruding end provided below the annular housing 63, and the outer wall of the intubation tube 616 protrudes out relative to the annular housing 63. The inner wall of the end is in the shape of a gap; an...

Embodiment 3

[0039] like Figure 2-4 As shown, the aluminum alloy smelting and degassing equipment, the vibration assembly 65 includes a convex point 651, an upper receiving pipe 652, an outer convex head 653, an annular box 654, a spring 655, a lower receiving pipe 656, a convex head 657 and a small ball 658. 62 is connected with the annular box body 654, an upper receiving pipe 652 is arranged in the annular box body 654 below the inlet pipe 62, and the upper port of the upper bearing pipe 652 is connected with the lower port of the inlet pipe 62; the side wall of the upper bearing pipe 652 is symmetrical The outer convex head 653 is connected, and the outside of the outer convex head 653 is connected with a number of convex points 651 at the inner wall of the annular box body 654; A lower receiving pipe 656 is provided, and the lower port of the lower receiving pipe 656 is connected to the upper port of the row pipe 66; A spring 655 is arranged symmetrically inside, and one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com