Self-propelled concrete vibrating trolley for ballast bed

A self-propelled, concrete technology, used in roads, tracks, laying tracks, etc., can solve problems such as the inability to ensure uniform concrete pouring, and achieve the effects of improving vibrating operation efficiency, reducing labor intensity and high operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

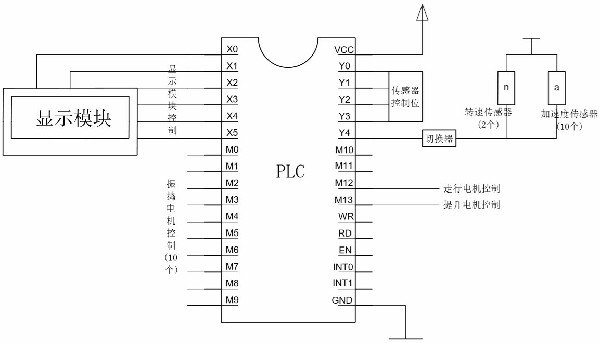

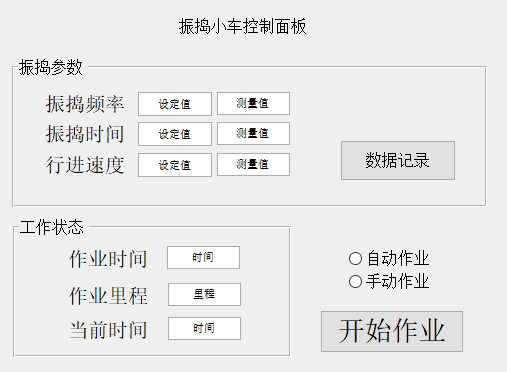

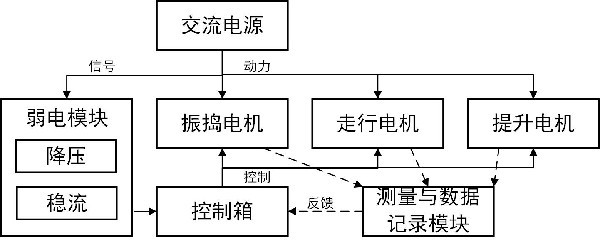

[0017] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary and are only used to explain the present invention, but not to be construed as a limitation of the present invention.

[0018] like figure 1 , figure 2 As shown in the present invention, a self-propelled concrete vibrating trolley used for a track bed, the main part is composed of a frame (11) and a lifting mechanism (14) that moves vertically relative to the frame (11). The bottom of the frame is equipped with a track wheel (5) and a traveling motor (10) that drives the track wheel (5). Four slide rails (3) vertically passing through the lifting mechanism (14) are installed on the outer side of the frame (11), and a lifting screw (2) vertically passing through the lifting mechanism (14) is installed in the center of the frame (11). , the lifting screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com