Diesel pressurization-liquid ammonia direct injection dual-fuel injector

A dual-fuel, injector technology, used in fuel injection devices, charging systems, machines/engines, etc., can solve problems such as energy waste, achieve accurate injection timing, prevent abnormal injection, and prevent wear and leakage problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in more detail below in conjunction with accompanying drawing example:

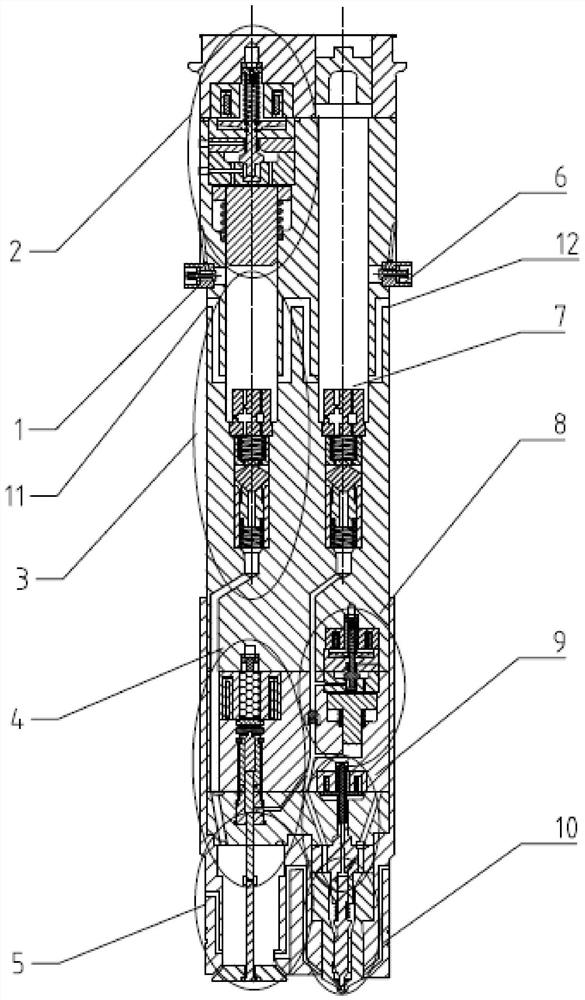

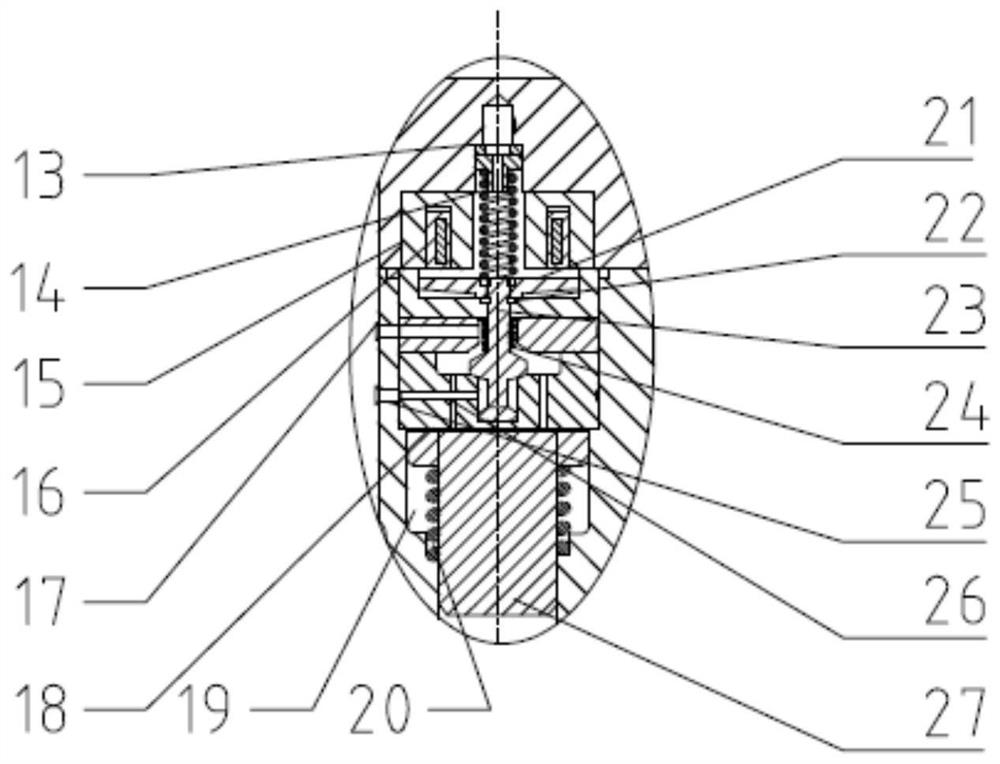

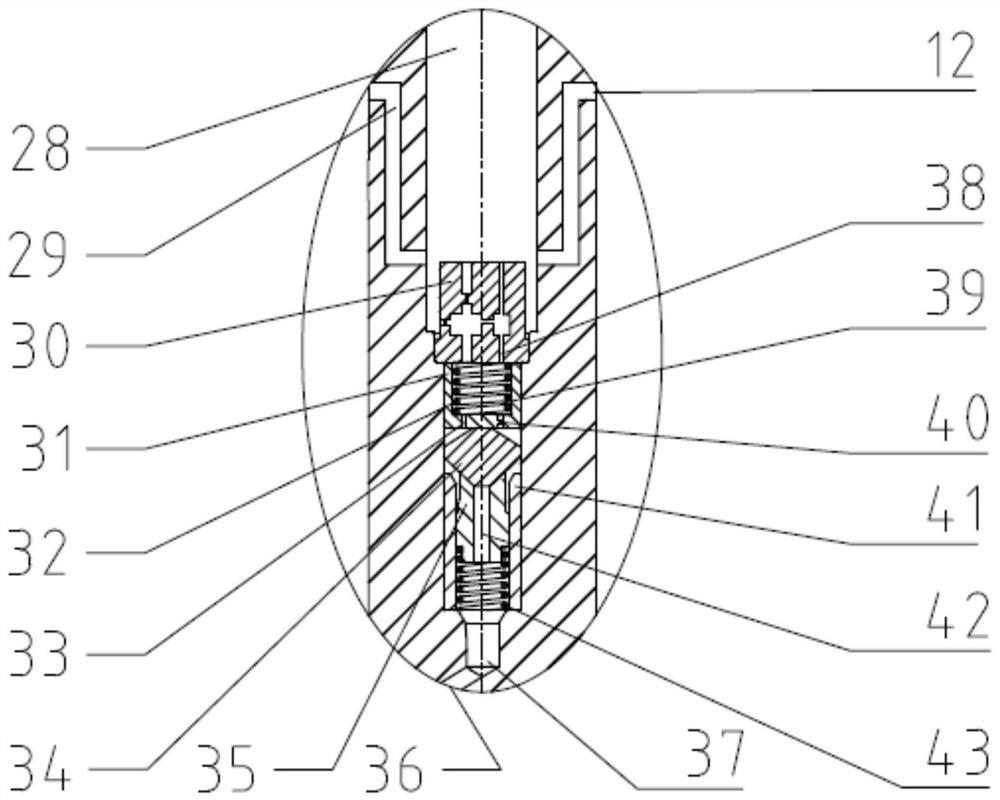

[0036]combine Figure 1-11 , figure 1 It is a schematic diagram of the overall structure of the present invention, a diesel supercharging-liquid ammonia direct injection dual-fuel injector, including a one-way ammonia inlet 1, a boosting module 2, a pressure storage resonance current limiting module 3, 7, and a gigamagnetic electromagnetic control actuator 4. Direct control type super atomization nozzle module 5, one-way oil inlet 6, auxiliary booster module 8, pressure balanced electromagnetic control actuator 9, needle valve eccentric self-adjusting nozzle 10, liquid ammonia heat management module 11, 12 . Realize high-pressure liquid injection of ammonia fuel into the cylinder to achieve full combustion. At the same time, the injection process is combined with thermal management design to adjust the pressure and temperature to control the phase change of amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com