Real-time industrial diagnosis method

A diagnostic method and industrial technology, applied in the direction of instruments, computer control, simulators, etc., can solve problems such as time-consuming, labor-intensive, lack, inability to monitor and feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

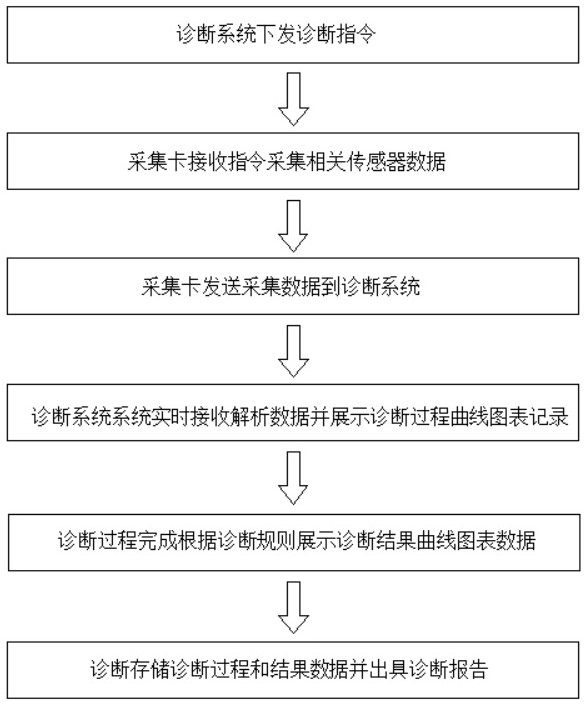

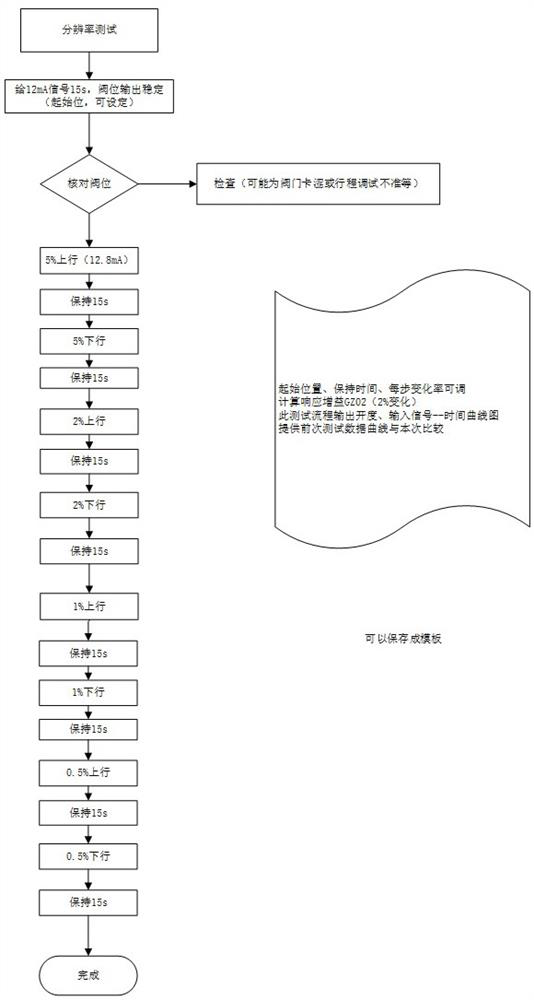

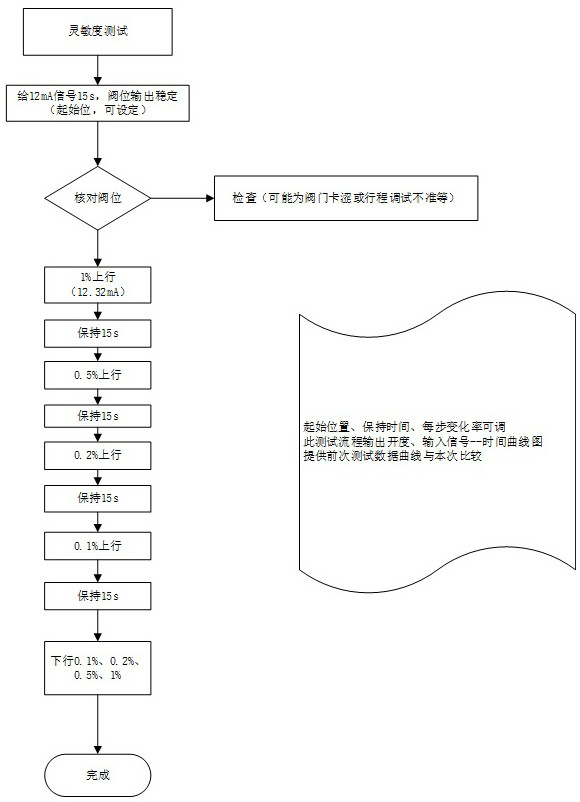

[0038] join figure 1 and figure 2 , the present invention relates to a real-time industrial diagnosis method,

[0039] After the diagnostic program issues diagnostic instructions, multiple signal sensors installed on the controlled equipment will input the sampling signals of diagnostic parameters (such as pressure signals, angle signals, displacement signals, etc.) collected into the sampling unit, and the sampling unit will convert the sampling signals into After the digital signal is transmitted to the main control MCU, the main control MCU transmits the signal to the industrial computer for diagnosis, analysis and processing through the network, and the industrial computer transmits the control signal to the main control MCU through the network according to the analysis and processing results, and the main control MCU outputs the signal through the analog quantity. The module transmits the control signal to the control unit of the controlled equipment, thereby realizing ...

Embodiment 2

[0051] The invention relates to a real-time industrial diagnosis method,

[0052] After the diagnostic program issues the diagnostic command, multiple signal sensors installed on the controlled device input the sampling signal into the sampling unit, the sampling unit converts the sampling signal into a digital signal and transmits it to the main control MCU, and the main control MCU diagnoses and analyzes the digital signal After processing, the main control MCU sends the corresponding generated control signal to the control unit of the controlled device through the analog output module according to the processing result.

[0053] see figure 1 , an industrial diagnostic system, the first and second embodiments above can be realized based on a diagnostic system, the system includes a sampling unit and a processing unit installed on a circuit board, and the circuit board is installed in the housing of the acquisition card :

[0054] The above-mentioned sampling unit converts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com