DNA sequence printing equipment fault detection method, system and device

A DNA sequence and printing equipment technology, applied in the field of fault detection of DNA sequence printing equipment, can solve problems such as drug contamination, unmatched production speed, and limited energy of staff, and achieve the effect of ensuring accuracy, high efficiency and rapid monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a DNA sequence printer, which includes an endless conveyor belt used for transporting test tubes, and an injection device, the injection port of which is used for spraying and injecting DNA medicine into the test tubes. The number of injection ports is set according to the actual situation. In this embodiment, the injection ports are air pressure injection ports.

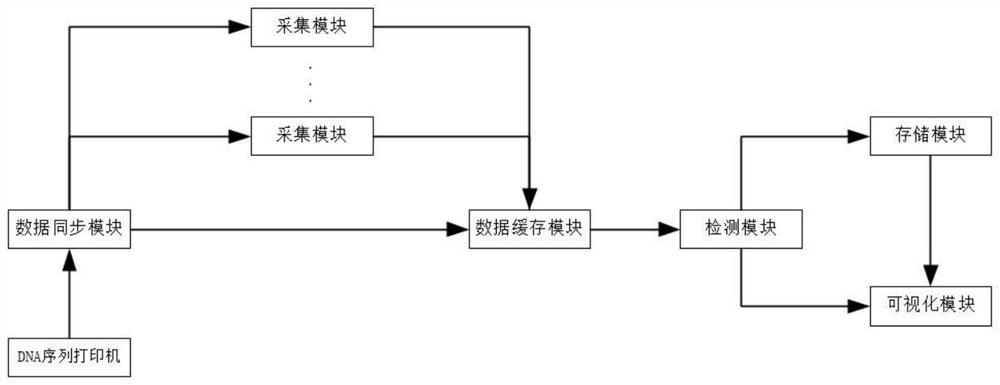

[0047] Such as figure 1 As shown, a DNA sequence printing device fault detection device in this embodiment includes: an acquisition module, a data synchronization module, a data buffer module and a detection module.

[0048] There are several acquisition modules. In this embodiment, the acquisition modules adopt CCD black-and-white industrial cameras, which are arranged in a circular array around the conveyor belt of the DNA sequence printer. The CCD black-and-white industrial cameras are aimed at the injection port of the injection device.

[0049] In this embodiment, a light source...

Embodiment 2

[0060] Based on the DNA sequence printing equipment failure detection device, this embodiment also provides a DNA sequence printing equipment failure detection method, including the following steps:

[0061] Synchronous acquisition step: obtain the print information of the DNA sequence printer; the print information includes several text data, determine the opening time of the injection port through the text data, and based on the opening time of the injection port, send a trigger signal to the acquisition module synchronously through the preset transmission code information , controlling the acquisition module to collect image data of the injection port; so as to realize the synchronization of taking pictures and injecting DNA medicine into the injection port.

[0062] Text verification step: verify the text data according to the transmission code information, and add the text data to the data buffer queue after the verification is passed. The text data includes the nozzle num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com