Logistics system damaged wood tray detection and alarm system and working method thereof

A logistics system and alarm system technology, which is applied in the direction of alarms, neural learning methods, biological neural network models, etc., can solve problems such as pallets that are difficult to distinguish, damaged wooden pallets, equipment and product damage, etc., to reduce product transportation consumption, Effect of extending service life, reducing equipment damage and product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

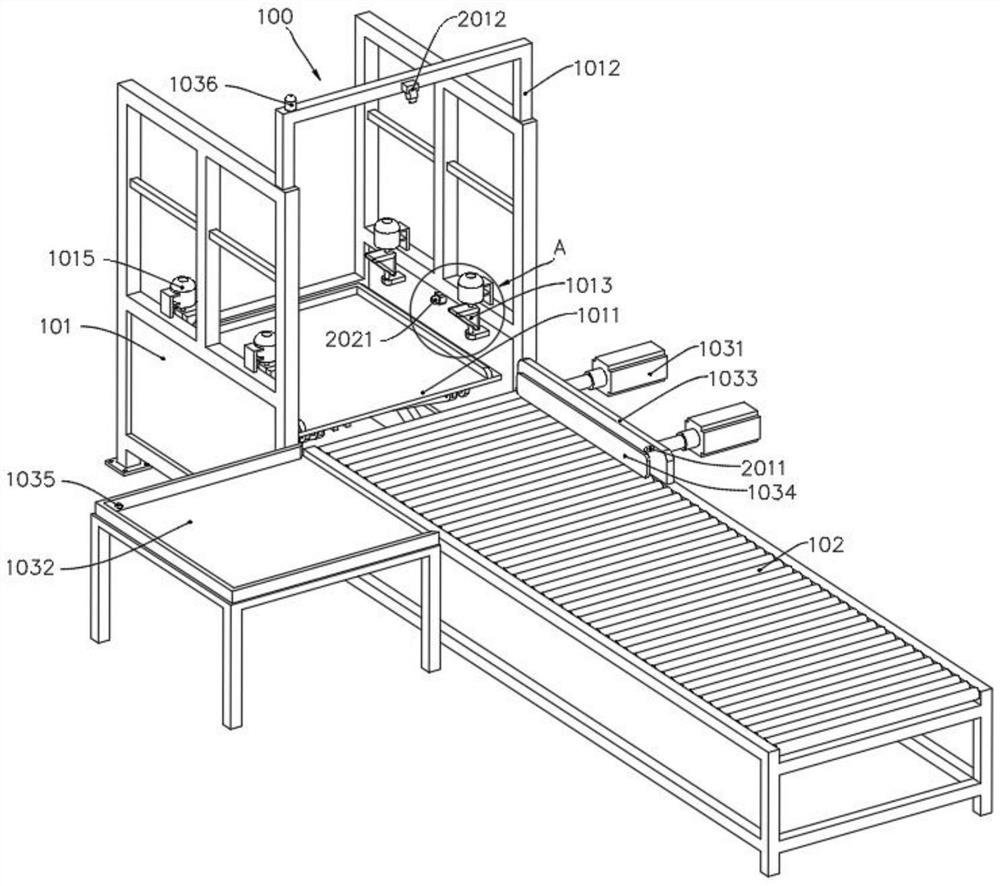

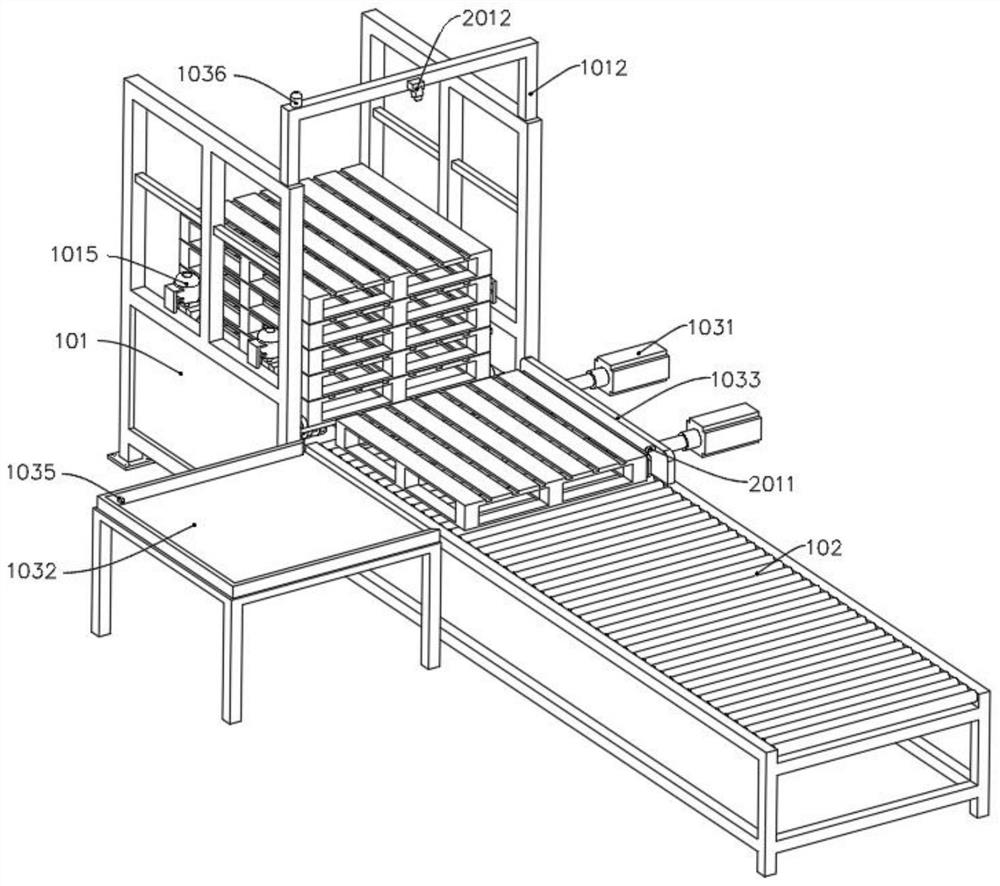

[0034] Refer to attached Figure 1-6 As shown, the present invention provides a technical solution: a detection and alarm system for damaged wooden pallets in a logistics system, including a conveying mechanism 100 , a detection mechanism 200 and a main control mechanism 300 .

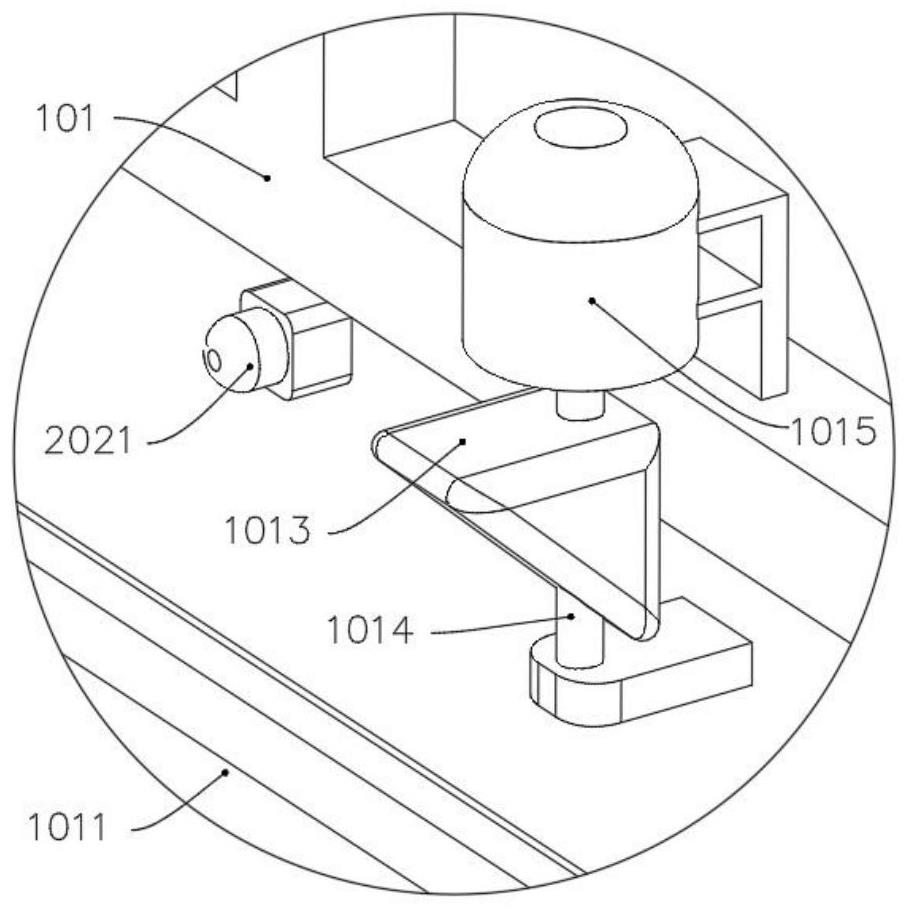

[0035] Refer to attached Figure 1-4 As shown, the conveying mechanism 100 includes a code separator 101, a transmission belt 102 and a rejecting machine 103. The inside bottom of the code separator 101 is provided with a jacking machine 1011, and the top of the code separator 101 is provided with a gantry 1012, and the inside of the code separator 101 is arranged symmetrically. There are four sets of shift forks 1013. The position of the shift forks 1013 corresponds to the fork holes of the wooden pallets. The code separator 101 is used for splitting the whole stack of wooden pallets. The logistics system is used in flow operation. The conveyor belt 102 is set on one side of the code sorting machine ...

Embodiment 2

[0046] Refer to attached Image 6 As shown, a working method for detecting and alarming damaged wooden pallets in a logistics system provided by an embodiment of the present invention includes the following steps:

[0047] S1, the pallet group is split, and the stacked pallet group is placed in the code separator 101. The servo motor 1015 controls the four sets of shift forks 1013 to recover, and the jacking machine 1011 starts to lift the entire pallet group. When the set height is reached, the servo motor 1015 Start to extend the shift fork 1013 and snap it into the fork hole of the second pallet at the bottom, and the jacking machine 1011 continues to descend to a position flush with the conveyor belt 102, waiting for the conveying signal;

[0048] S2, detection of the underside of the wooden board. After step S1, a gap is formed between the second pallet on the bottom layer and the bottom pallet. At this time, two sets of infrared sensors 2021 send out detection signals. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com