Ore grinding machine comprehensive operation state online detection device and automatic control method

A technology for detecting device and operating state, applied in the field of mineral processing, can solve the problem that it is easy to be affected by voltage frequency changes, grinding body loss or small fluctuations in mill speed, etc. problems, to achieve the effect of reducing the lack of manual judgment experience, strong practicability, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0018] The invention provides an online detection device and an automatic control method for the comprehensive running state of a grinding machine.

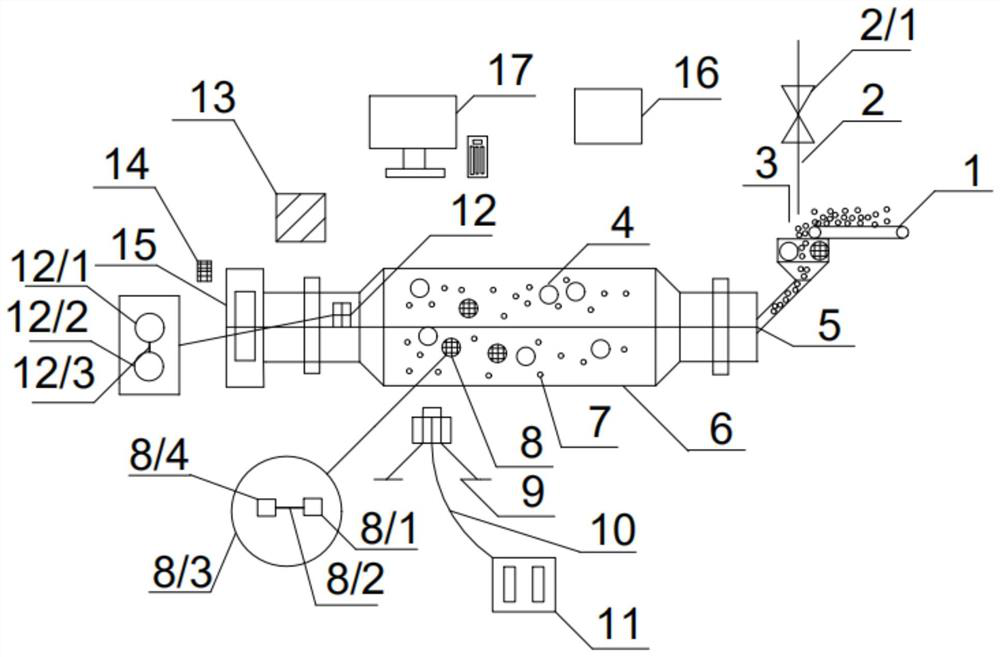

[0019] Such as figure 1 As shown, the device includes a feeding belt conveyor 1, a water pipe 2, an additional grinding medium device 3, a grinding medium 4, a material inlet 5, a grinding machine 6, an intelligent material 8, a grinding noise detection device, and a vibration monitor 12. Inverter 13, wireless base station 14, discharge port 15, expert control system 16, upper computer 17 and electromagnetic valve 2 / 1, wherein the grinding noise detection device includes grinding noise detector 9, shielded cable 10 and analyzer 11 , the vibration monitor includes acceleration sensor 2 12 / 1, connection line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com