High-elasticity flame-retardant fiber band glue removing equipment for wind energy cable

A flame-retardant fiber and high-elasticity technology, which is used in the field of high-elasticity flame-retardant fiber belt degumming equipment for wind energy cables, can solve the problem of inability to accurately control the thickness of nylon-based fiber cloth to remove glue, affect degumming and drying, nylon-based fiber cloth. The fluff of the base fiber cloth is disorganized and other problems, so as to save the cleaning work, facilitate degumming and drying, and achieve the effect of neat fluff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

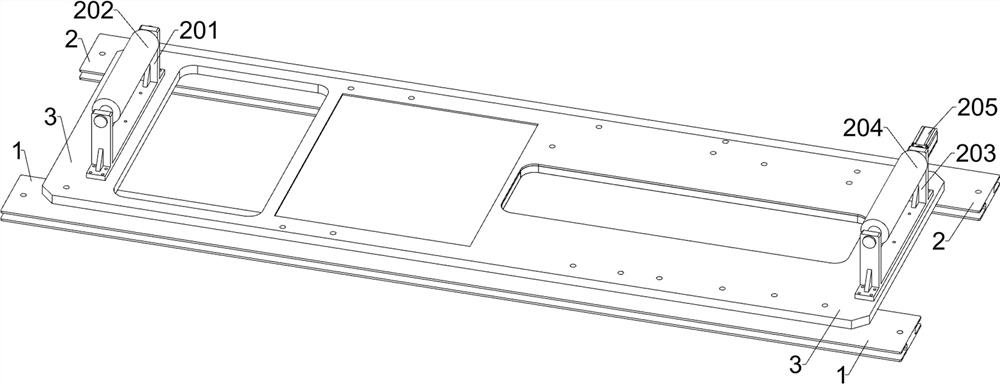

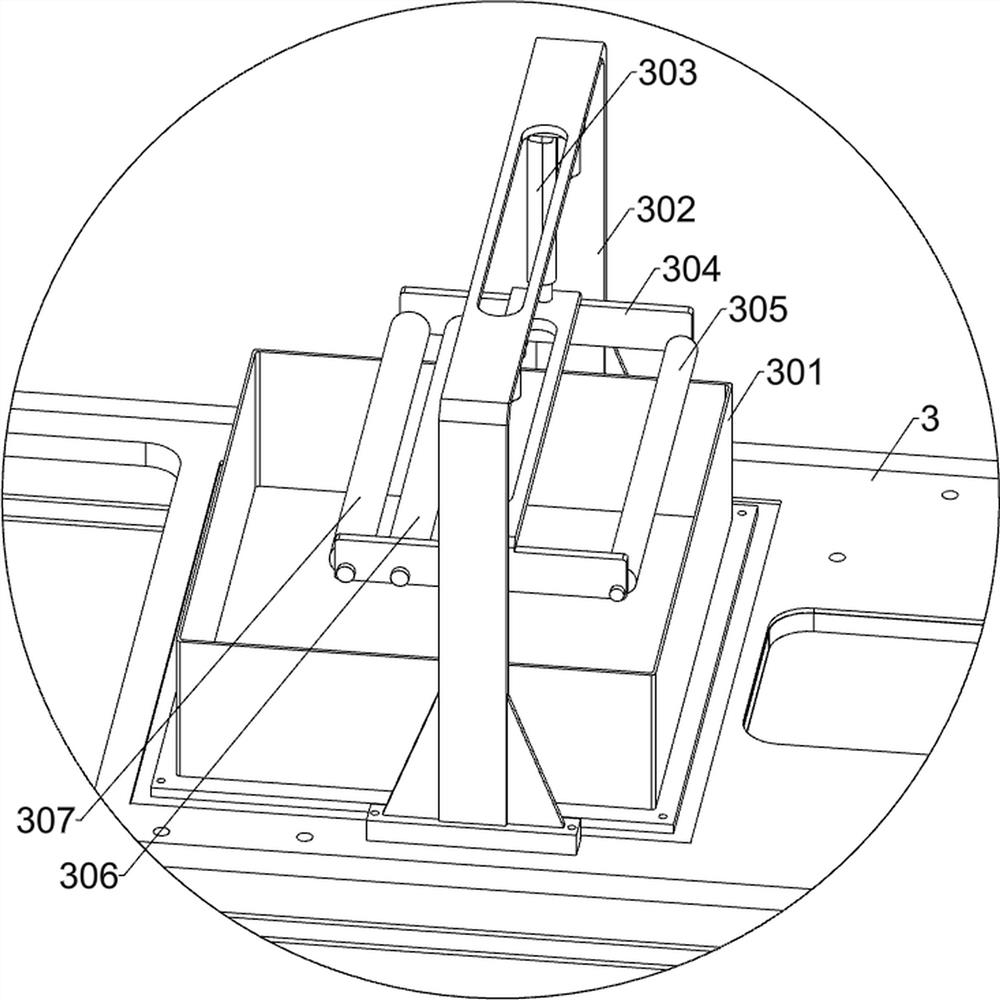

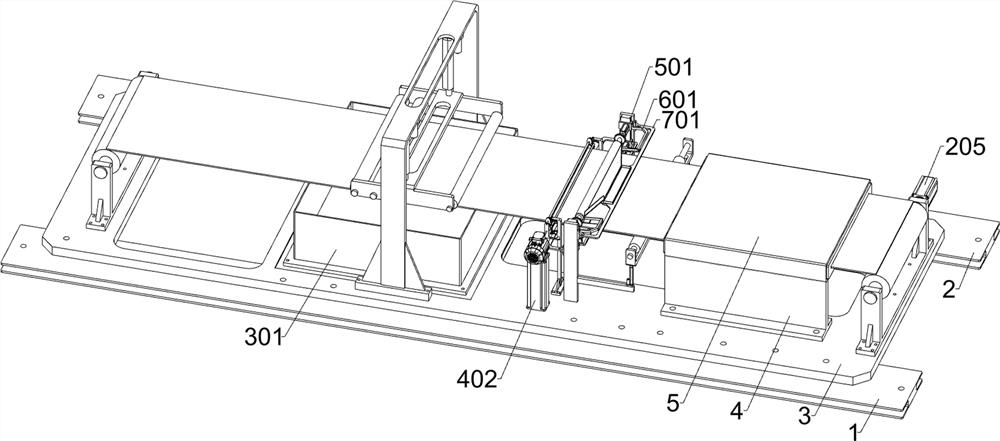

[0033] A kind of high elastic flame retardant fiber tape cleaning equipment for wind energy cables, such as Figure 1-11 As shown, it includes a first bolt base plate 1, a second bolt base plate 2, an installation base plate 3, a fixing frame 4, a dryer 5, a winding unit, a dipping unit, a wrinkle-removing tensioning unit and a glue-removing unit; the first Bolt base plate 1 and second bolt base plate 2 upper surfaces are bolt-connected with installation base plate 3, and installation base plate 3 is provided with the collection area for collecting excess glue; installation base plate 3 upper surface right side is welded with two fixing brackets 4; A dryer 5 is installed on the upper surface of a fixed frame 4; a winding unit is installed on the upper surface of the installation base plate 3; a dipping unit is installed on the left side of the upper surface of the installation base plate 3; ; The glue removal unit is installed in the middle of the upper surface of the installa...

Embodiment 2

[0043] On the basis of Example 1, such as figure 1 and Figure 12 As shown, an edge glue cleaning unit is also included, and an edge glue cleaning unit is installed on the right side of the glue removing unit. Plate 604 and the second cleaning plate 605; two second drive members 503 right sides are respectively fixed with a second connecting frame 601; two second connecting frames 601 opposite sides are respectively fixed with a deflector 604; two The opposite side of the second connecting frame 601 is respectively fixed with a first cleaning plate 603, and the two first cleaning plates 603 are located on the left side of the two deflectors 604; Plate 604, the first cleaning plate 603 at the rear contacts the deflector 604 at the rear; the third connecting frame 602 is connected by bolts between the two third driving parts 504; the third connecting frame 602 is fixed with two front and rear symmetrical The second cleaning plate 605.

[0044] Wherein, the two deflectors 604 ...

Embodiment 3

[0048] On the basis of Example 2, such as figure 1 , Figure 13-14 As shown, it also includes a roller rubber cleaning unit, and the left and right sides of the two T-shaped plates 501 are equipped with a roller rubber cleaning unit, and the roller rubber cleaning unit includes a fourth connecting frame 701, a collection frame 702 and a cleaning frame 703; two The upper left part of the T-shaped plate 501 is bolt-connected with two fourth connecting frames 701, and the middle part of the upper surface of the two fourth connecting frames 701 is fixedly connected with a collection frame 702; the opposite sides of the two fourth connecting frames 701 are respectively welded with a cleaning frame 703.

[0049] When the two glue removal rollers 508 remove excess glue on the surface of the fiber cloth, the cleaned glue remains on the surfaces of the two glue remover rollers 508. The removal thickness of the excess glue on the surface of the fiber cloth by the two glue removal roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com